In high-risk environments, fraudsters will develop sophisticated methods to collect and reuse security labels from original packaging, for example. Securikett is working with committed customers on a systematic approach to close the loopholes in anti-tampering technology.

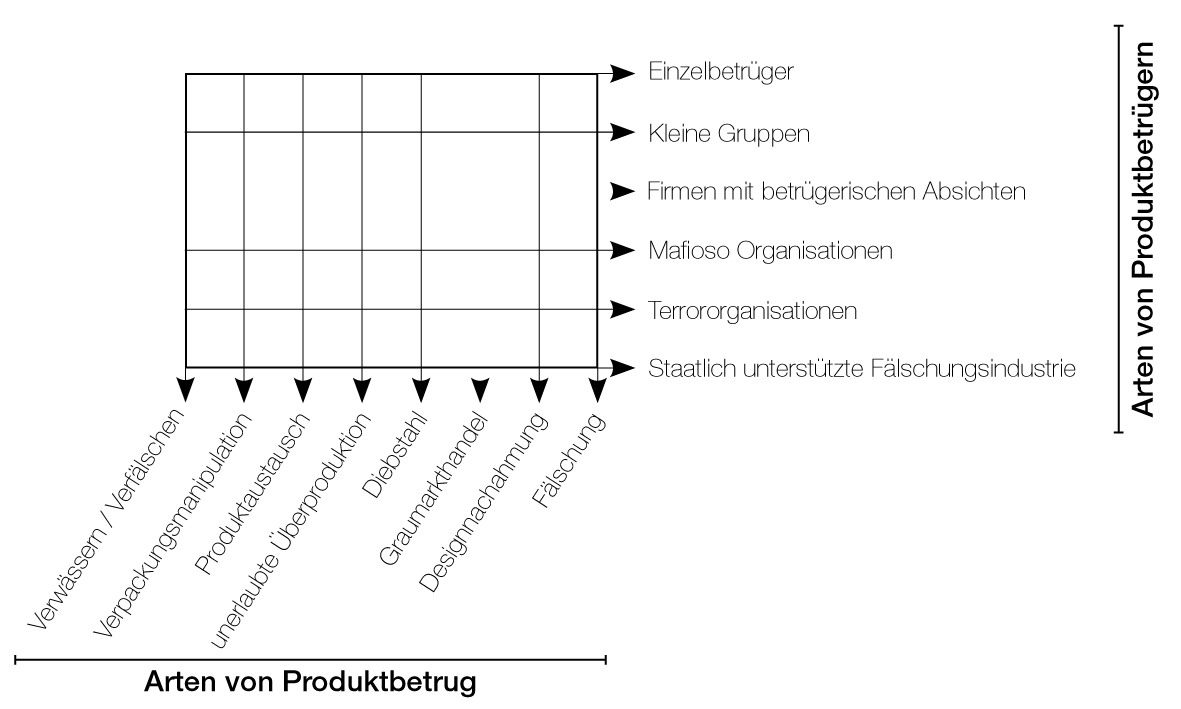

Dr Marietta Ulrich-Horn, Co-Managing Director of Securikett Ulrich & Horn GmbH, Wiener Neudorf (Austria), is driving the development of the seamless tamper protection for high-risk products and markets in order to prevent the use of illegally obtained security labels. Both the market environment and the risk aspect of a product should be included in the risk assessment. In the currently emerging ISO standard TC292 „Security and resilience“ two categories are compared in order to assess the risk of manipulation of a product in a specific market.

Danger from manipulation attempts

To make a folding box tamper-proof, it may be sufficient to tape the flaps shut. This method prevents less serious attempts at fraud, such as the undetected removal of a blister pack from the box in a shop or storeroom.

In order to come into possession of security labels Fraudsters several possibilities, e.g:

- Copying and reprinting the security labels,

- Careful removal of the labels without destroying them,

- Soften the adhesive with heat (e.g. with a hairdryer) to make it easier to remove,

- Weakening of the adhesive due to freezing temperatures,

- Soaking the labels and box in a liquid such as water or solvent to soften the adhesive on the underside. In this case, the folding box can usually not be reused and a reprint is required.

The aim of such manipulation can be to remove the contents from the original box or replace them without being noticed. More often, especially when the effort is high, fraudsters collect intact security labels from used cartons to use on newly printed cartons. In the pharmaceutical sector, counterfeit, illegally manufactured products can be contaminated or ineffective as well as having different properties than expected. In addition, the perception of the Brand value negatively influenced and Liability claims can cause additional damage to the rights holder of original products. But how can you ward off threats from fraudsters?

[infotext icon]Similar to folding cartons, the described criminal activities in the spirits industry aim to refill bottles with fake alcoholic contents or to defraud consumers in the area of price refunds or purchase incentive campaigns[/infotext].Overt and covert security features

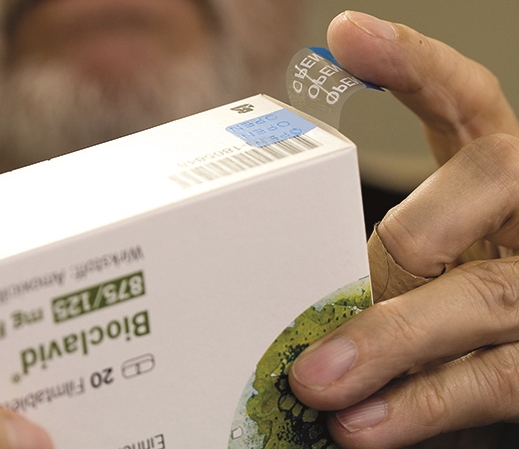

To prevent security seals from being imitated and mass-produced, they should be recognisable as such by both overt and covert security features. Nowadays, unique identification codes are used, so-called unique identifiers, The use of security codes and apps contributes to the efficient, clear identification and traceability of individual products. Corresponding apps are not only able to identify the codes, but also help the user to understand the appearance and overt security features of the labels.

Special security technologies

Special security technologies are required for removal tests 2 to 5 in order to detect tampering attempts. For products and markets where the probability of fraud or its effects are low, a seal with a strong adhesive in combination with predetermined breaking points may be sufficient. However, attention must be paid to the balance between predetermined breaking points and adhesive strength. The conventional Cardboard fibre tear-off is not always as safe as it seems. If the uncoated carton is completely torn open, the counterfeiter can stick the carton back under the label without being noticed.

Instead of relying on a high adhesive and bonding strength of the adhesive that is matched to the cardboard, the VOID technology a reliable predetermined separation point in their colour layers, which makes them a robust technology. Any conventional attempt to peel off a label leaves a pattern or lettering such as „VOID“ on the box.

The costs incurred by the so-called. VOID effect The patterns displayed can be customised to the design and shape of the security seal, e.g. with a lock symbol or text. Different colours and translucent labels that allow underlying texts and barcodes to be read are possible.

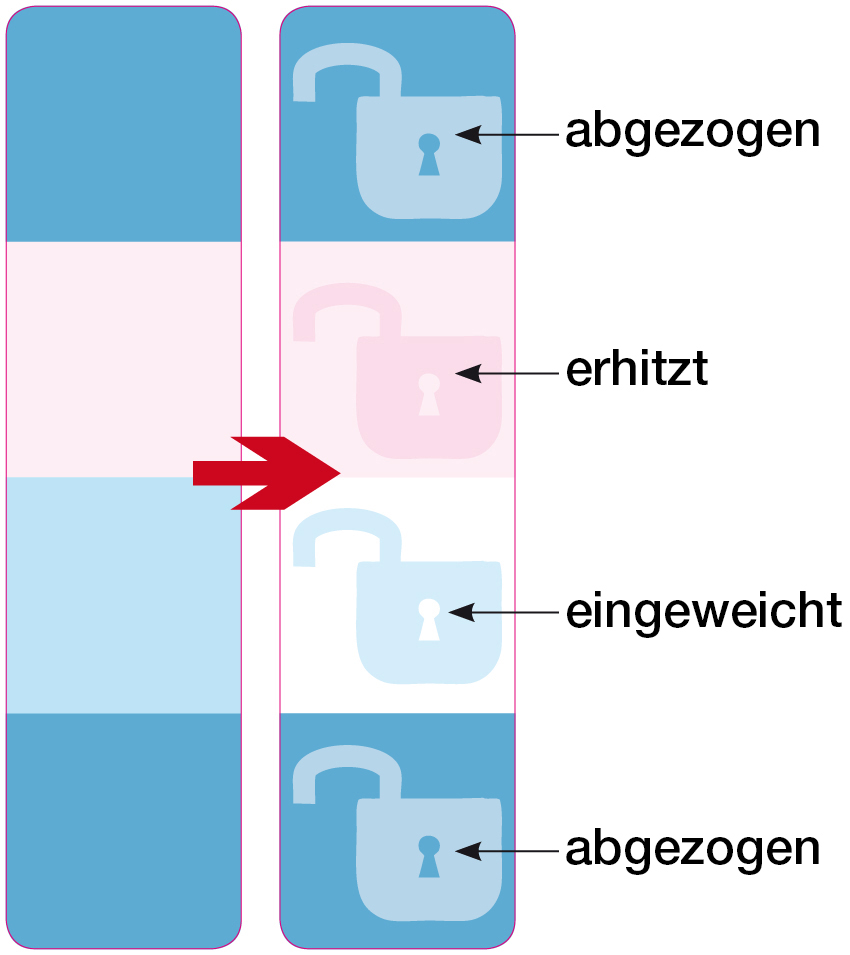

Different VOID zones

To withstand attempts at tampering using cold spray, the use of adhesives that remain effective even at sub-zero temperatures after 24 hours of application is recommended. Things get tricky when fraudsters use heat to remove labels. However, the use of heat-reactive ink, which changes colour irreversibly at a temperature of 80 °C, for example, can also solve this problem. „Heat gap“ close.

What if used cartons are soaked to remove and collect labels? Recently, a new VOID technology has been developed specifically to remove these labels. „Dishwashing gap“ to close. To withstand even the most persistent tampering attacks, security labels should have different VOID zones:

- VOID zones consisting of separable colour layers to indicate the opening,

- VOID zones that indicate heat-based manipulation,

- VOID zones that indicate soaking of the labels together with the box.

Communication with the consumer

It is also important to communicate to the consumers of the products which security features are used. Examples of this are references to the First-opening protection on the packaging such as „Do not use if the first-opening seal is missing or damaged“. This means that the consumer knows what should be present and can check whether the protection is actually in place. Such measures also show the end consumer that the manufacturer is keen to reassure its customers that they are actually buying genuine goods.

When it comes to protecting customers from the increasing professionalism of counterfeiters, it is important to Proactive measures become even more sophisticated. A risk analysis and a solid risk minimisation plan put decision-makers on the right path in the area of tamper protection.