Web guiding systems are required wherever flat material webs are produced, processed or finished. A typical application is the printing industry for paper, packaging and labels. Sensors ensure that the web is guided precisely, even at high production speeds.

When a paper web runs through a printing press, it is guided through the machine by numerous rollers. To achieve a perfect end result, the position of the web in the printing press must be defined and always correct. A web guiding system ensures that the web is guided precisely and keeps the material on track even at the highest web speeds, so that it is always positioned correctly.

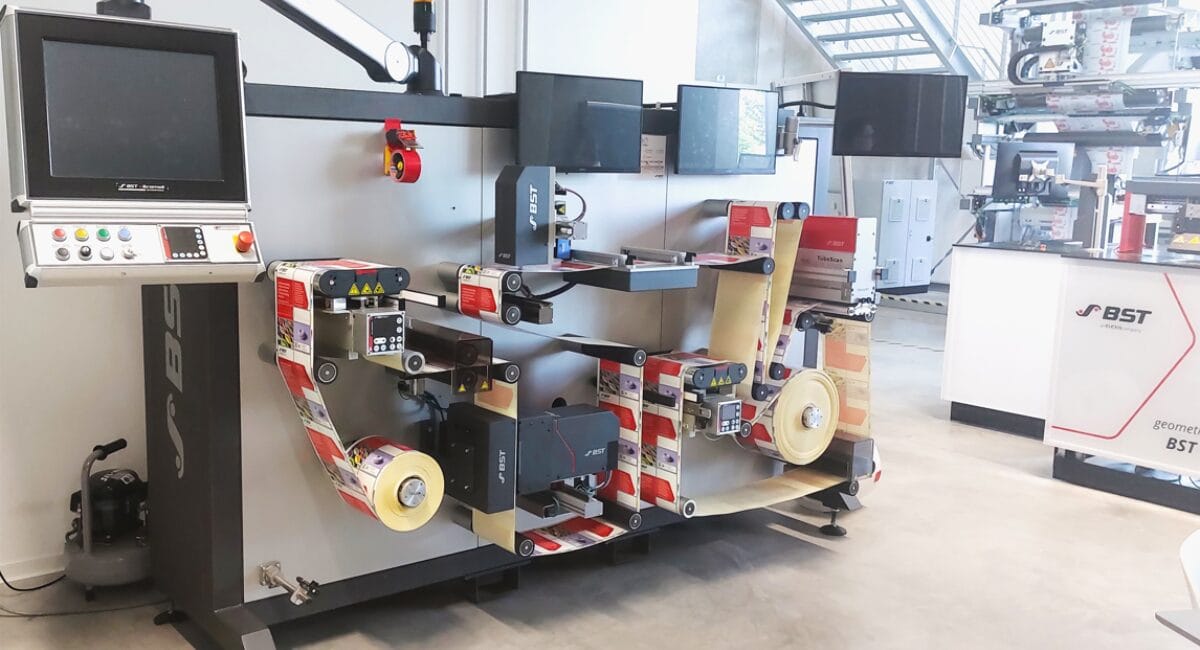

Bielefeld-based BST GmbH, a medium-sized manufacturer of systems for the web-processing industry, uses the following as an important component of its web guiding systems the linear sensor MMP from Metallux. Its task is to continuously record the absolute actual position of the drive and thus enable precise control of the web run.

The absolute measuring, wear-free sensor is hermetically sealed and, with a height of less than two millimetres, particularly flat. The pick-up is contactless with a magnet guided at a distance from the sensor. The MMP is operated in the low voltage range. The output signal can be processed by all common control systems become.

Sensor with long service life

The MMP not only has good resolution, precision and measuring accuracy. It is robust, wear-free and has a very long service life of up to 50 million cycles. These advantages make it the ideal sensor for high-speed machines, enabling precise and reliable control.

However, BST does not use a standard version, but A customised solution. The sensor is not mounted on a film with an adhesive backing, as is usually the case, but integrated directly into the design of the drivet. The special shape of this assembly makes it easy to install. The dimensions and the cable are also customised.

Metallux manufactures exclusively in Germany: From sample quantities to large series of several hundred thousand units. Modern, automated production processes are utilised. The equipment includes a clean room as well as high-quality inspection and testing facilities.