Logistics service provider MS Direct is using AI-based picking robotics from Sereact for automated picking at the port of its AutoStore for the first time. The system processes around 1,500 orders a day - even at night.

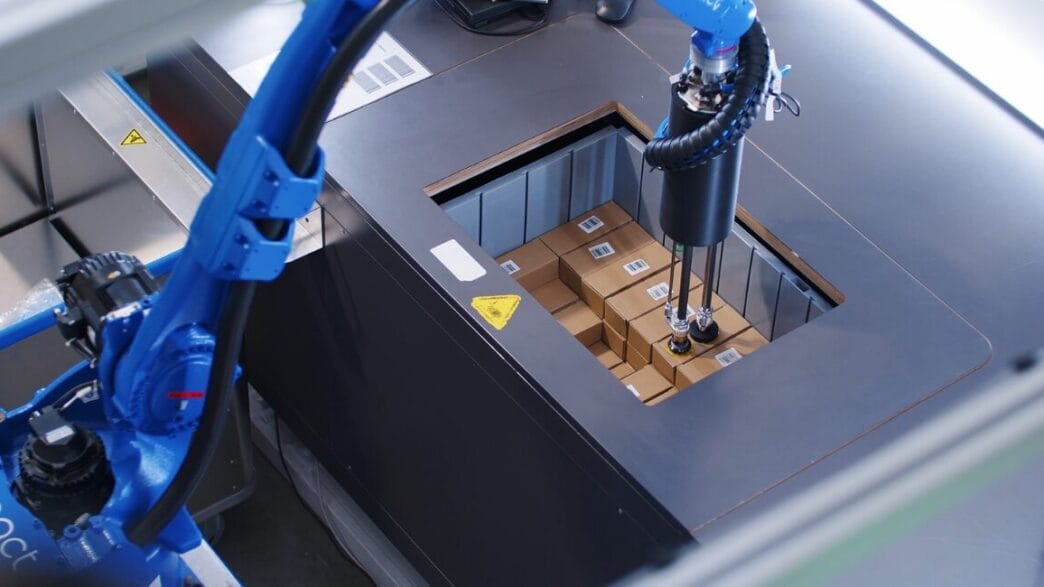

MS Direct AG has taken a further step towards automation at its largest fulfilment site in Arbon (Switzerland). For the first time, picking at its AutoStore port has been automated. An AI-based pick-and-place solution from the software company Sereact is being used, which, according to the company, does not require any prior training for new items.

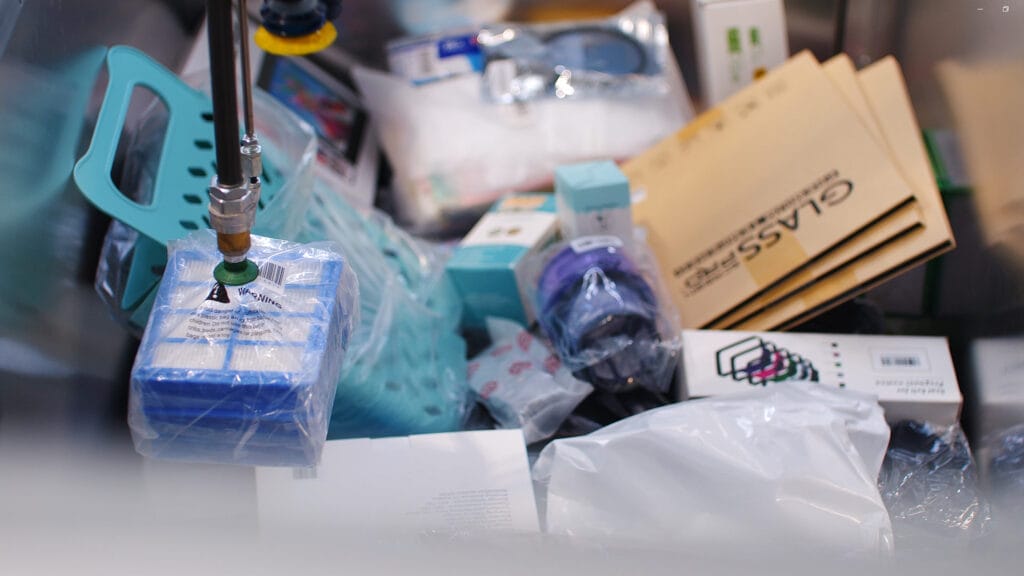

The starting point for the project was the high variety of items in the warehouse. According to the company, there are more than 60,000 different SKUs in circulation in the AutoStore system at the Arbon site. This heterogeneity had previously made further automation in the picking process difficult, as many products were unknown to the picking robot that was first tested. Picking was therefore mainly carried out manually.

Support through artificial intelligence

The Sereact solution now analyses each object visually in real time and recognises characteristics such as shape, material or colour. On this basis, the system independently selects a suitable picking strategy. This is made possible by an AI-supported vision language action model that can apply different picking strategies without manual data acquisition.

According to MS Direct, the robot now processes around 1,500 single-pick orders per day. Its use during the night is particularly relevant: whereas the AutoStore system was previously mainly used during the day, the robot now takes over preparatory picking tasks for the following day during the night. This increases throughput and reduces the need for personnel at off-peak times.

The aim of the project was to automate simple and repetitive tasks and deploy employees specifically for more complex tasks. According to the company, the susceptibility to errors in AutoStore has also been reduced and process reliability increased. In economic terms, the investment was amortised after around nine months.

MS Direct is currently looking into gradually expanding automated picking robotics to other AutoStore ports at the Arbon site. Automation is also being considered at other locations as soon as the technical requirements are met. In addition, the company says it is in dialogue with Sereact about the possible use of other AI-based solutions, such as for inventory monitoring and quality control.

Source: Sereact