Machine manufacturers are increasingly demanding hygienic design components. With its MAXOLUTION®-The SEW-Eurodrive GmbH & Co. KG offers a functionally scaled robotic solution.

The kit consists of three interconnected freely combinable packages. The Controller package includes the Control system, e.g. MOVI-C® CONTROLLER UHX85A-R, the visualisation and the software. The Robot axle package includes the axle modules, e.g. MOVIDRIVE® modular and the servomotors, e.g. synchronous motors from the CMP series, including the cabling. The Robot mechanics package includes the Servo gearbox such as the new PxG planetary servo gearbox®, compatible with common robot kinematics. Convenient teach-in functions and simple parameterisation enable effortless implementation in the shortest possible time.

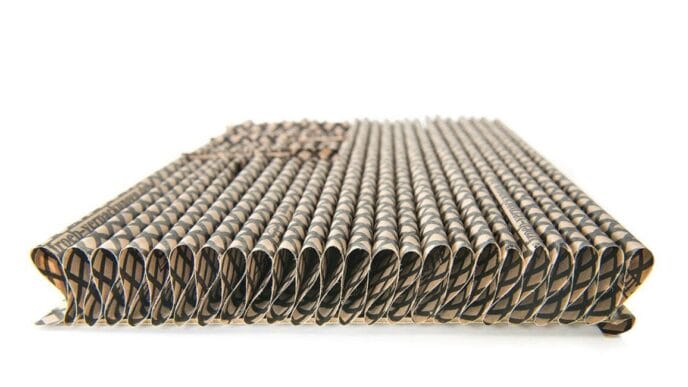

Hygienic design is already possible in the basic version as well as a special design with a closed stainless steel housing.

SEW-Eurodrive combines reliable Drive and control technology and Software to comprehensive, easy to integrate Solution packages. These leave the classic value creation in the form of design, integration, installation and commissioning to the machine manufacturer. The packages are optimally harmonised. The overall solution is Tailored to standard robot mechanisms, which the customer can obtain from a SEW-Eurodrive approved provider of his choice.

Customised individual packages are also available on request, including safety technology. This customisation is not limited to the design of the technology alone. Rather, the packages offer the required free space, to find solutions in the Hygienic design for example for the Food industry or the Pharmaceutical industry. The manufacture of medicines must highest hygiene standards which are regulated by strict guidelines. And in food processing, there are more and more robot-assisted work areas in which fish or meat is filleted, sorted or placed in packaging.

SEW-Eurodrive at Fachpack 2019: Hall 3, Stand 233