The possibilities of packaging finishing are so varied and differentiated that they can convey not only value but also brand characteristics. As a global leader in hot stamping and coating technology, the KURZ Group from Fürth offers a comprehensive range of products for surface finishing and decoration.

How a product is perceived by the consumer depends to a large extent on its packaging. Without appropriate Presentation of goods a product is not perceived as high quality by the consumer and is overlooked at the PoS. Packaging enhancement is a key means of visualising the value of a product. In particular Metallisations are excellently suited to emphasising the character of brands and outlining brand profiles.

The methods for generating metallic effects have increased in recent years. However, established processes have not been superseded by new finishing techniques, but have effectively complemented them. Brand manufacturers and processors can now choose finishing methods that are tailored to the specific technical, economic and design requirements of individual projects. This diversity has contributed to the fact that Packaging is currently being refined more than ever.

[infotext icon]Gold and silver tones stand for preciousness and exclusivity, silver-diffractive designs for freshness and purity, colourful glitter effects underline creative, young product lines,matt shiny metal colours convey classic elegance, metal-brushed designs signal a high technical standard[/infotext].

The Short Group develops and produces decorative and functional coatings applied to carrier films for a wide range of applications: metallised, pigmented and holographic embossed films for packaging or print products, surface finishes for electronic devices or automotive parts, protective and decorative coatings for furniture or household appliances, authenticity markings for branded goods and differentiated coatings for many other applications.

Classic hot stamping for everything noble

Hot stamping technology provides metallisation with a special gloss. The coating reflects the light like real metal. This is why hot stamping designs give packaging a particularly elegant appearance. This makes the process the first choice for exclusive brands and luxury packaging. Premium lines of private labels are also often decorated with hot stamping foils. Another advantage of the process is the ability to create artistic metallised reliefs. Raised, recessed, single and multi-level reliefs, impressive textured embossing and micro embossing can be generated in a single operation with hot stamping. Relief and textured hot stamping is not only a visual delight, but also appeals to the sense of touch. The haptic perception creates further added value and increases the incentive to buy.

Cold foil transfer for unlimited colour variety

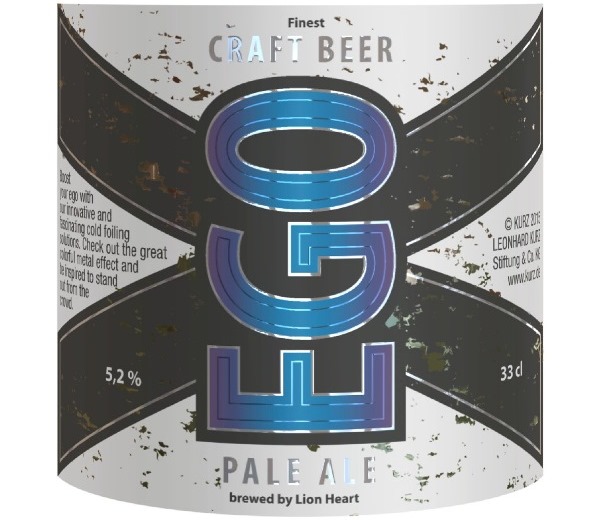

Cold foil is transferred inline and can be integrated into the printing process as flexibly as a fifth colour. Only one colour is usually Silver-coloured cold foil used. An infinite variety of colours can then be created by overprinting in bright metal colours can be generated. Corporate design colours can also be generated in metallic tones in this way. As no embossing clichés are required for this process, it is also suitable for smaller print runs.

Cold foil transfer thus meets the trend towards decreasing batch sizes. There is a continuing trend towards numerous product variants, seasonal packaging, special series and sizes. Cold foil transfer offers an economical way to create effective metal accents on this packaging too.

DigitalMetal for metal effects

Digital Metal was developed by Leonhard KURZ as a finishing method for the digital printing world. In this process, the metallisation layer is transferred to digitally pre-printed sheets with toner using the DM-Liner transfer machine. In a further step, the digital or offset colour overprint is applied. This also produces all conceivable bright metal colours. The process also provides a special opportunity for product valorisation.

The value of a product is measured, among other things, by its speciality. What is rare and not permanently available is considered valuable. Digital Metal creates this special feature through metallised individualisation such as personalisation, numbering or personal design elements. With DigitalMetal, packaging can be decoratively individualised in digital printing from a print run of one at a manageable cost.

Inline foiling for high-quality metal decoration

The inline foiling finishing technology was also developed by Kurz, in collaboration with the machine manufacturer Isimat. Cylindrical containers made of glass or plastic can be decorated at high speed using inline foiling. This creates shiny metal designs in any colour and motif. The designs are borderless transfer and adhere firmly to the substrate. They offer a much higher quality look than labels or decals. Inline foiling motifs look almost like handicrafts, but are produced in a highly industrialised and very economical decoration process. This process can be used to Glass and plastic finishes that could previously only be realised in the paper and cardboard sector.

Decorative variety for autonomous brand presentations

The possibilities for enhancing packaging with decorative metallisation have grown. Brand manufacturers can choose between various processes so that the finishing can be customised to the print run, choice of motif and the possible budget of the respective project. In terms of design, today's variety of decorations offers new possibilities for autonomous brand presentations. Every technique has a specific refinement character and sets special design accents. This independence can be used to strengthen brand profiles.

[infotext icon]With 4,500 employees in eleven plants in Europe, Asia and the USA, 24 international subsidiaries and a worldwide network of representatives and sales offices, the KURZ Group manufactures and sells a comprehensive range of products for surface finishing, decoration, labelling and anti-counterfeiting, rounded off by an extensive range of embossing machines and embossing tools. In addition, KURZ continuously invests in new technologies and develops innovative solutions for the integration of functions into surfaces[/infotext].