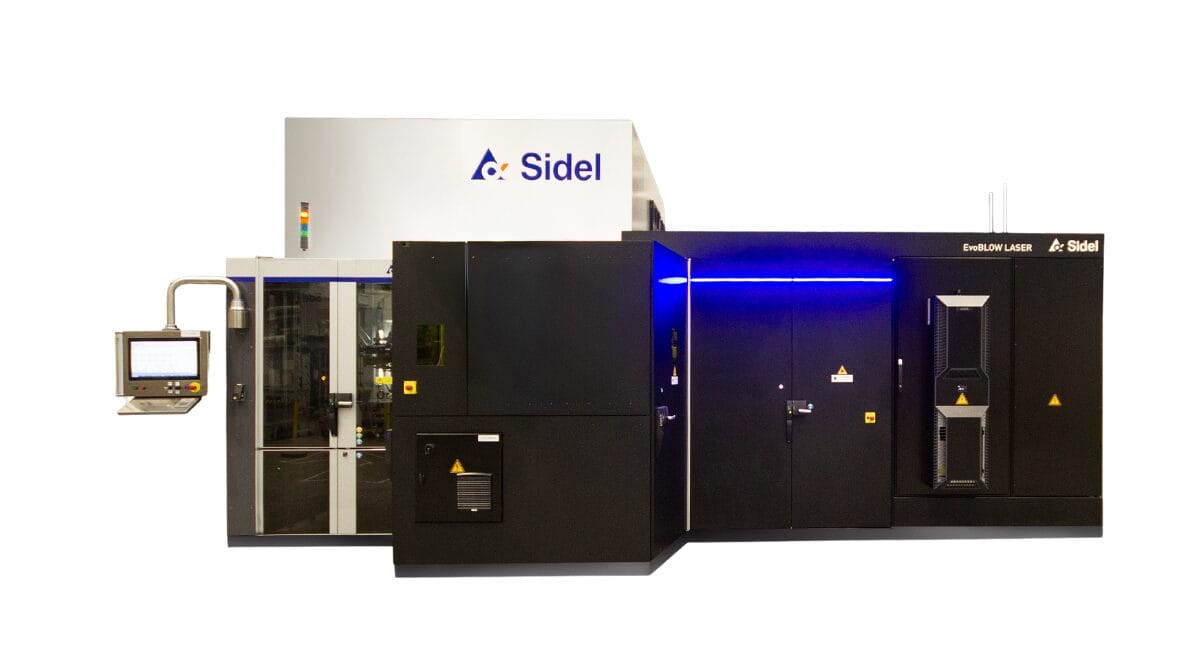

With the EvoBlow Laser, Sidel is presenting a new blow moulding technology for PET and rPET packaging at drinktec. The system replaces the conventional halogen technology with a laser-based heating process.

According to the company, the precise control of heating enables up to 36 heating lines instead of the usual eight zones. This allows material thickness and distribution to be controlled more precisely, which allows for lighter and at the same time more stable bottles. Invisible „power rings“ reinforce the structure of the containers without restricting their design. In addition, weight reduction is also possible in areas that were previously considered unsuitable, such as directly under the neck of the bottle.

Another advantage: The laser-operated ovens do not require any warm-up time. They deliver consistent results from the very first preform, regardless of the ambient conditions. Downtimes can be overcome without waiting times, as No cool-down phases or stand-by mode required are. Operation should also be easier, thanks to a touch interface and lower maintenance requirements, among other things.

According to Sidel the technology also improves the processing of recycled material. rPET reacts more sensitively to fluctuations, which can be compensated for more quickly and precisely with the laser process. At the same time, the amount of waste in the production process is reduced.

Beverage bottler Refresco has already used the EvoBlow Laser in a practical test. „After 45 years of halogen technology, we are now entering a new era. I am convinced that laser oven technology will become the new standard,“ explains Coert Michielsen, Chief Supply Chain Officer at Refresco.

Source: Sidel

Sidel at drinktec 2025: Hall A6, Stand 361