At LogiMAT, the Bluhm Weber Group will be showcasing its portfolio of current labelling systems with labels, ink and laser. The solutions are specially designed to meet the requirements of intralogistics.

Smart labelling technology from Bluhm Weber ensures that Processes in intralogistics automated and accelerated be used. This minimises errors and avoids unnecessary expenditure at the same time. The basis for a smooth process is formed by industrial labelling solutions with ink, laser or labels, which deliver the best results even at high speeds and work reliably even in harsh production conditions with cold or dust. The innovative solutions from Bluhm Systeme can integrated into existing logistics processes and have a long service life.

The correct application and legibility of QR codes, serial numbers or content streamline a variety of intralogistics processes. Depending on the requirements, this can be done with high-resolution inkjet printing, laser or labels. In internal logistics, clearly legible labelling ensures that goods are correctly pre-sorted and can be found again. Automated processes are also less prone to errors than manual interventions and are constantly being optimised in modern operations.

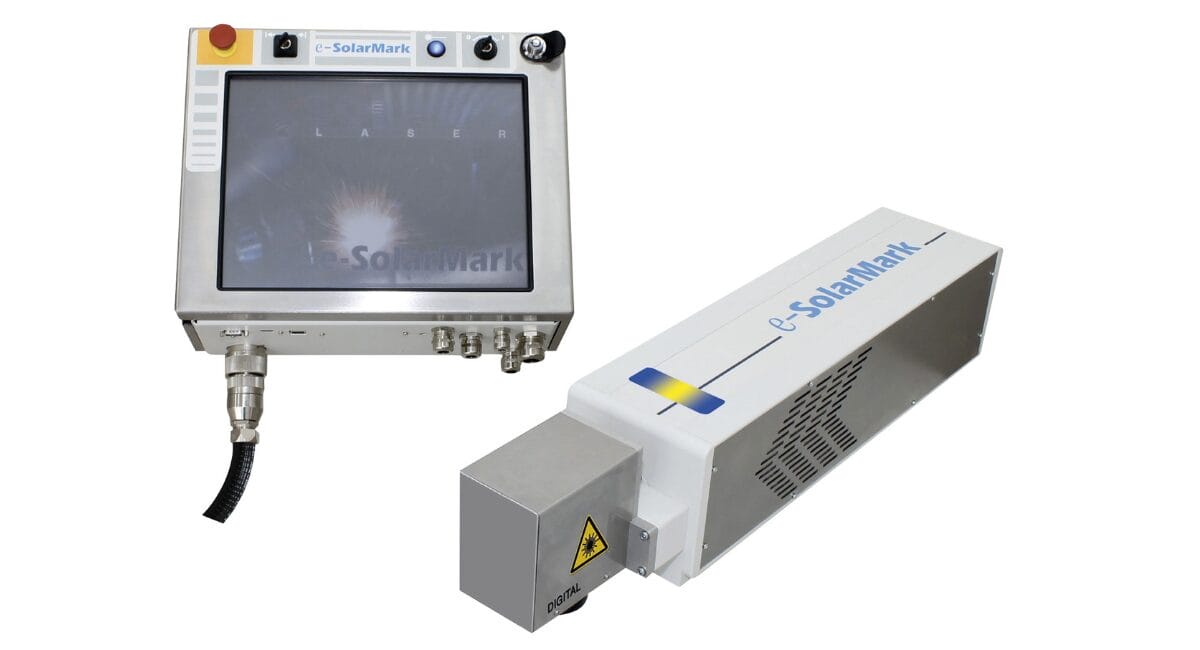

Ink-based industrial printers print high-resolution codes or information directly onto the goods or cartons and can be flexibly integrated into the existing production line. Modular labelling systems apply labels fully automatically and at high speed, thus ensuring fast internal processing. Components and workpieces can be clearly labelled and identified by laser.

Source: Bluhm Systems

Bluhm Systeme at the LogiMAT: Hall 2, Stand 2A05