The trend towards self-administering medication at home is creating new challenges in the pharmaceutical industry. Faller Packaging has developed smart labels with printable temperature or light indicators to make it easier for patients to take their medication themselves.

The healthcare and pharmaceutical market is growing rapidly - and the technologies behind it are constantly evolving. Faller Packaging is following the current trend towards intelligent solutions for medicines that are administered at home with a new product line: Temperature or light indicators on the labels increase user-friendliness and safety Self-Application Medicines (SAM).

Self-application medicines should be as easy and safe to use as possible. This is the only way to achieve treatment compliance. Incorrectly taken medication can have unpleasant consequences for patients. For example, if insulin is too cool, it may cause pain during application. In the worst case, the effectiveness may even be delayed due to the change in viscosity.

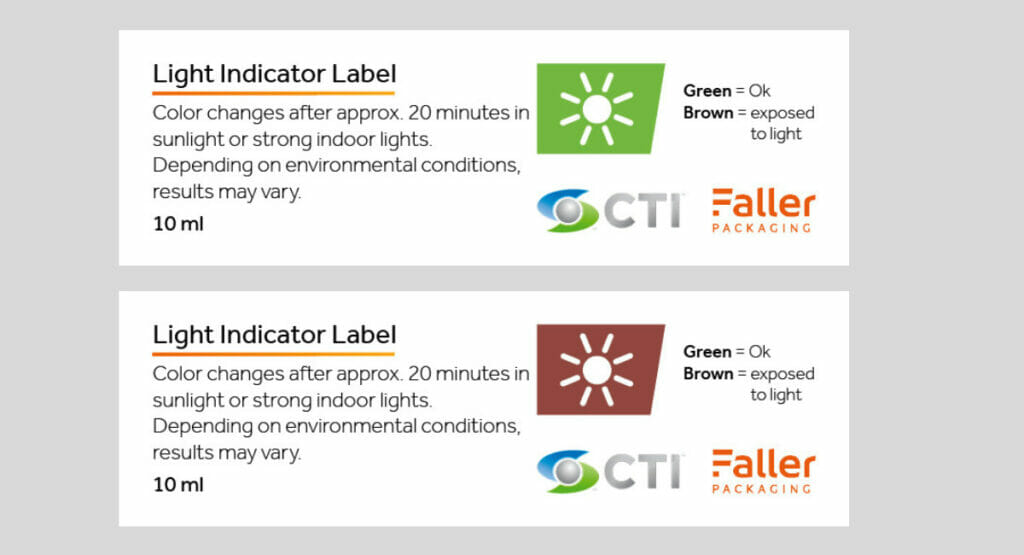

In order to remedy this and further minimise the cognitive burden for the patient, the Faller Packaging together with its partner CTI (Chromatic Technologies Inc) developed a label with printable temperature or light indicators. As soon as the indicator changes colour, the user can easily recognise when the medication can be administered. The label can be customised to meet the individual requirements of pharmacists - both in terms of design and the required indication range.

The customer can easily print the indicator on the label without electronics. It can then be further processed and applied to the product like any other standard label.

„Our product innovation process (PIP) is based on an agile stage-gate procedure that is optimally tailored to our requirements. The labels are a good example of how we use the PIP to drive new ideas forward. „

Sarina Diebold, Product Marketing Manager at Faller Packaging

In order to pool interdisciplinary knowledge and expertise, interdisciplinary teams at Faller Packaging We develop new products in short cycles and bring them to market maturity. The innovation process for the new labels began around two years ago.

Direct dialogue with potential pharmaceutical companies at a very early stage played an important role, says Sarina Diebold. „This gives us the certainty that the new product is optimised for the user. There is great interest in the labels. We are currently talking to a number of customers and discussing possible applications together. We will then develop the customised product together with the customer and our partner CTI. With this label, it is important to understand exactly what the indicator is supposed to represent. If required, the shape, colour, temperature range, branding, text and more can be customised. Depending on the desired application, the sensor is reversible or irreversible.“

Source: Faller Packaging

Pharmaceuticals and cosmetics - More news

Multi-Color Corporation ensures delivery capability

Alltub takes over La Metallurgica

Limburger Packaging Group integrates Müller & Bauer

Sharp invests massively in expanding packaging capacities