Belgian frozen vegetable producer Greenyard Frozen has achieved significant savings in product loss and energy consumption by using smart checkweighers from Mettler-Toledo.

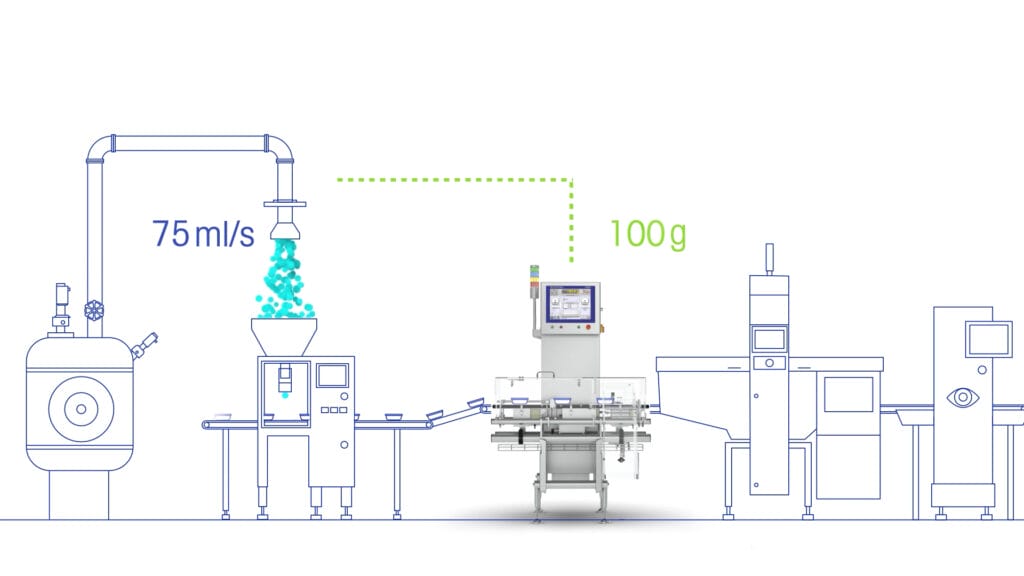

The company processes large quantities of frozen food on high-speed lines - previously with a significant safety margin for the filling weight. Overfilling of up to 40 grams per pack was intended to prevent underfilling, but led to enormous losses of raw materials. The solution: C33 PlusLine checkweighers from Mettler-Toledo, which are equipped with automated fill level adjustment. They continuously analyse the filling quantity, automatically readjust in the event of deviations and thus ensure that the target weight is reliably maintained.

Automated weight correction in real time

The function for intelligent fill level adjustment of the C33 PlusLine checkweigher from Mettler-Toledo was tested in a pilot trial last year - with promising results. The checkweighing system continuously monitors the average product weight and automatically adjusts the margin of the multihead weigher from 40 grams to ten grams per 1 kg bag during filling.

In practice, Greenyard was able to reduce overfilling on a line from 0.69 per cent to just 0.14 per cent. With a line output of 60 bags per minute, this corresponds to a raw material saving of around 1.8 kilograms per minute.

Fast amortisation and high flexibility

As a result of the successful introduction, six packaging lines have now been converted to the new technology. The project was accompanied by comprehensive technical support and training from Mettler-Toledo. According to the company, the cost of integration was low - and the investment was amortised within a few months.

„We can now control the excess weight much better and stay closer to the desired filling weight. This leads to product savings, avoids waste and makes the process more efficient. Ultimately, it's an investment that quickly pays for itself.“

Dominiek Vierstraete, Technical Manager at Greenyard Frozen Belgium

In addition to the economic benefits, the solution also fulfils ecological requirements: Less overfilling means less waste, less energy consumption and an improved carbon footprint. For everyday packaging, this means more precise processes, less waste - and a step towards sustainable production. Thanks to its modular scalability, the solution can also be transferred to other production lines and locations.

Source: Mettler-Toledo