Heidelberger Druckmaschinen AG and its subsidiary Gallus will be presenting an innovative range of digital solutions at Labelexpo Europe 2023 to underpin their commitment to „intelligent, connected printing“.

With an annual growth rate of around six per cent, the Digital label printing is an attractive growth market for Heidelberg, which is therefore increasingly turning to digital solutions. The latest innovations emphasise the desire to drive this digital transformation forward together.

„The new solutions that Heidelberg and Gallus have developed together address the key challenges that players in the market face on a daily basis, such as the shortage of skilled labour and the demand for greater productivity.“

Dr Ludwin Monz, Chairman of the Management Board at Heidelberg

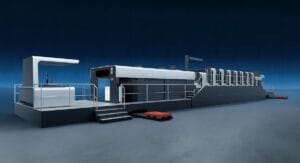

Labelexpo also marks the European trade fair debut of the new Gallus One digital label press. Launched in August 2022, the press has been specifically designed to reduce the total cost of ownership (TCO) for digital roll-to-roll label production with a Maximum automation and cloud-based technologies and thus bring digital label printing to the masses. Gallus One thus gives brand manufacturers access to cost-effective, sustainable and high-quality digital labels for the first time.

To further optimise the TCO benefits, Gallus recently launched the new Gallus One with inline converting. This new solution combines all important functions inlineThe company's portfolio includes a digital printer with an inline flexo station, a semi-rotary die-cutter that can change a job within a minute and process up to 70 metres per minute, and inspection systems to ensure the highest quality and minimise waste.

At the trade fair, Gallus will also be presenting the new digital printing unit (DPU) available for the Gallus ECS 340 flexo press. It transforms a conventional Gallus ECS 340 into a Gallus Labelfire 340 hybrid printing press - albeit a hybrid one. without the need for additional investment in the platform. This means that customers are now able to utilise all the flexibility and versatility of digital printing, but with the reliability and precision of conventional printing and finishing technology.

The trade fair will also provide a platform for presenting the new Heidelberg Customer Portal (HCP), which automates almost every customer contact. As a true industry innovation, future versions of the solution will be also offer prediction functions based on artificial intelligence (AI) and provide recommendations for increasing productivity, reducing maintenance costs and increasing profitability. The new platform is expected to save customers up to 35 per cent of time and money on average.

Source: Heidelberg

Heidelberg - More news

Heidelberg takes over service for Schubert in Brazil

Study shows: paper packaging is becoming significantly more important

Heidelberg acquires technology and trademark rights from Polar Mohr

Networked label printing