Packaging made from moulded fibre parts is exceptional - moulded fibre parts protect products and the environment: buhl-paperform GmbH, Burbach, is one of the leading manufacturers of customer-specific and ecologically high-quality packaging solutions made from the secondary raw material waste paper. Production processes that are optimised to meet individual challenges are available.

With currently nine production lines and three finishing lines, buhl-paperform is one of the trend-setting and recognised companies in the field of paper production. constructive packaging solutions made from recycled paper. The two production sites in Burbach offer customers a high degree of supply security and flexibility. The specialist's portfolio ranges from individual packaging solutions to a variety of standard solutions that are suitable for many transport situations, are available at short notice and offer the same product benefits as individually manufactured moulded fibre parts.

Available qualities of moulded fibre parts

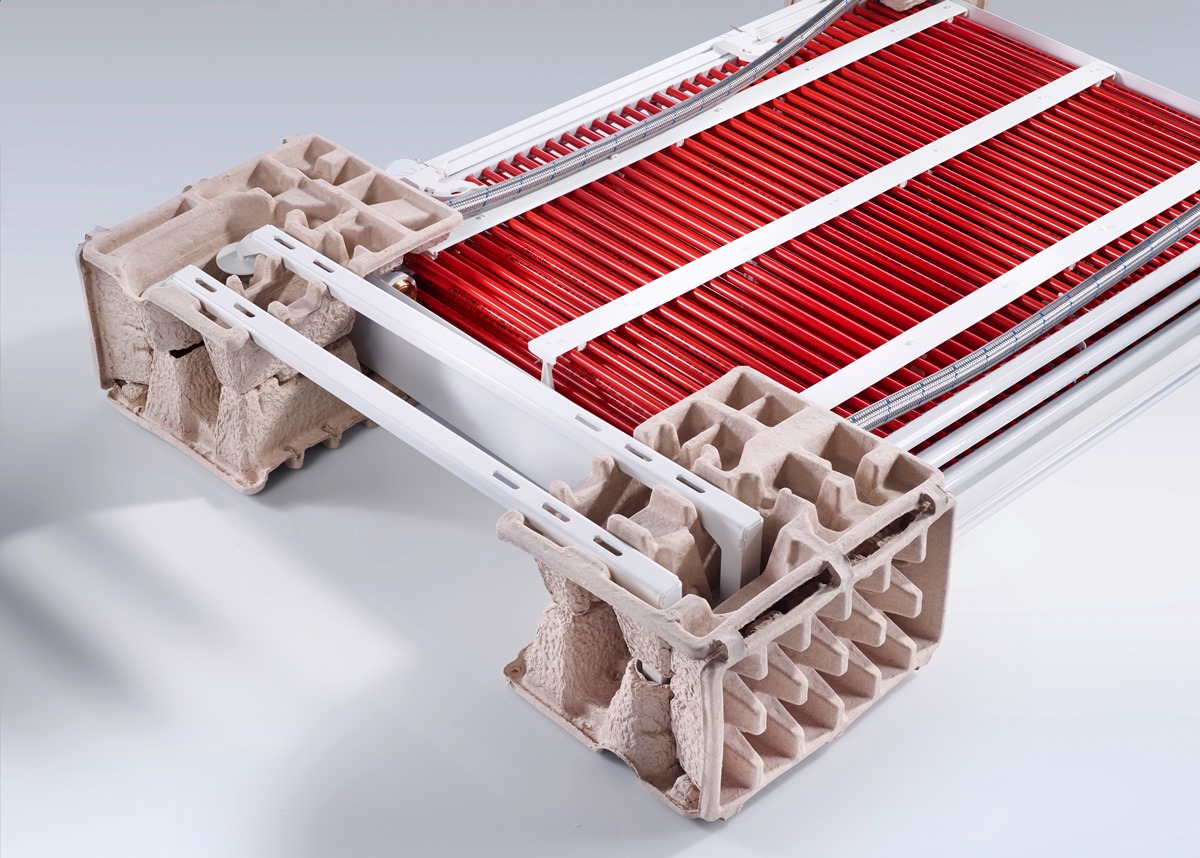

The moulded fibre parts (also known as cast fibre parts) from buhl-paperform are used in the food industry, in the chemical and solar industries, in medical and sanitary technology, in the furniture and fittings industry or in the automotive industry and for household appliances. A distinction is made between different production technologies:

Moulded fibre parts for product protection and transport

NormTec moulded fibre parts are made from up to 100 percent recycled paper and are characterised by High rigidity and Stability under heavy load from. This manufacturing process focusses on the padding and protective functions. The geometry of the moulded fibre part adapts perfectly to the product contour and thus guarantees secure padding.

Famoulded parts for transport protection and presentation

In this manufacturing process, a PressTec fibre moulded part is smoothed and given its final shape in an additional work step - post-pressing. This significantly reduces the space required for transport and storage. The good flatness of the products ensures trouble-free machine runability. A PressTec fibre moulded part is characterised by optimised handling in the packaging process and a Precise fit from.

Moulded fibre parts for the highest demands

The FineTec quality is made from up to 100 percent recycled paper (this applies to all fibre castings). The special feature of this process is the Increased strength of the moulded fibre parts compared to the PressTec process, meaning that up to 30 percent of the normal material input can be saved. Thanks to their smooth surfaces, FineTec moulded fibre parts are particularly suitable for use in Fixation of products and the locking of precision components.

Packaging development

At the centre of packaging development are the individual requirements customers' requirements for the product to be packaged, for simple handling and optimised packaging in the production process, for the customer's internal logistics processes and for the safe and simple removal of the product from the packaging.

From determining the specific requirements for the packaging through the design and development phase to the testing and approval of a sample part and the subsequent implementation of the customised packaging solution at the customer's premises, the entire project process for the optimum moulded fibre packaging is supported by a team of experts.

Special solutions for protective packaging

The moulded fibre parts SafePac are universally applicable protective packaging made from 100 per cent recycled paper, which are characterised by a patented cushioning mechanism and therefore a high degree of elasticity. The cushioning elements absorb pressure and shocks and thus prevent damage to the product.

GlassPac is protective packaging that has been specially developed for the transport of glass bottles. Many of these packaging solutions are UN-approved and can then be used for shipping hazardous goods.

With its Additive products the company also offers solutions for special requirements, e.g. increased protection against corrosion or moisture. Examples range generally from moulded fibre trays for food or contact lenses to moulded fibre pads for technical devices and components or medical products and even a base for the Gardena garden hose.

Everything but eggs: the egg packaging principle

We have Christoph Buhl, the head of the company, about the potential and special features of moulded fibre parts made from recycled paper.

pj: Mr Buhl, how did everything start with the production of your fibre moulded parts? Who came up with the idea and what was the market like at the time?

Christoph Buhl: The idea was born Beginning of 1992, when I discussed the avoidance of petroleum-based packaging with my father (and company founder) Ernst Buhl. At that time, as is still the case today, the moulded fibre industry was mainly involved in the production of food packaging, such as egg packaging and fruit crates, as well as solutions for the medical sector, such as kidney dishes, which are part of the basic equipment in every hospital and doctor's surgery, in huge quantities. Only with the widespread introduction of the digital CAD development of customer products, the optimised development of upholstery was also gradually implemented.

pj: Where do you stand today with your production programme?

Christoph Buhl: Today, as in 1996, the focus is on advising customers and developing an optimally customised solution. This often does not work with the standard range, which means that the proportion of customised developments is over 90 per cent.

pj: How do these solutions differ from those of other providers?

Christoph Buhl: Our sales force consists exclusively of experts in the field of packaging development and product development in a wide range of material groups. In close, trusting cooperation with our customers, it is thus possible to create a truly customised solution that meets the Best possible protective function with optimum handling offers.

pj: What development are you particularly proud of? Which challenges were particularly complicated?

Christoph Buhl: The development of an industry solution for the dispatch of Glass bottles in the hazardous goods area posed a particular challenge. We are proud that many of our customers use them in both fully automated and manual applications for the worldwide shipping of hazardous goods.

[infotext icon]When buhl-paperform GmbH was founded in 1996, the installation of the first FineTec production line in Germany set the course for technological leadership. Interested parties and customers benefit from a holistic consulting concept, starting with the joint qualified recording of the requirements and their implementation in the design phase through to support with customised logistics[/infotext].