Somic has been recognised as a mechanical engineering specialist in the food and non-food industry since 1974. The company was founded by Manfred and Hildegard Bonetsmüller in a small workshop in Vogtareuth, Upper Bavaria. Today, 50 years later, the company is based in Amerang in Chiemgau and is one of the leading manufacturers in the end-of-line packaging sector.

With just four employees, the team initially tapped into customers in the dairy industry in the first few years after the company was founded with products such as wrapping packaging machines, double-stitching machines for blue cheese and mixing and treatment systems for sour milk cheese. In 1986, after around ten years on the market, the company founder recognised the potential for the company's development in the world of packaging machines. One of the first machines from this period is the KA 20 carton erector designed for dessert cups. The machine for erecting and gluing carton blanks, combined with an automatic stacker for carton crates, achieves an output of 800 cartons per hour.

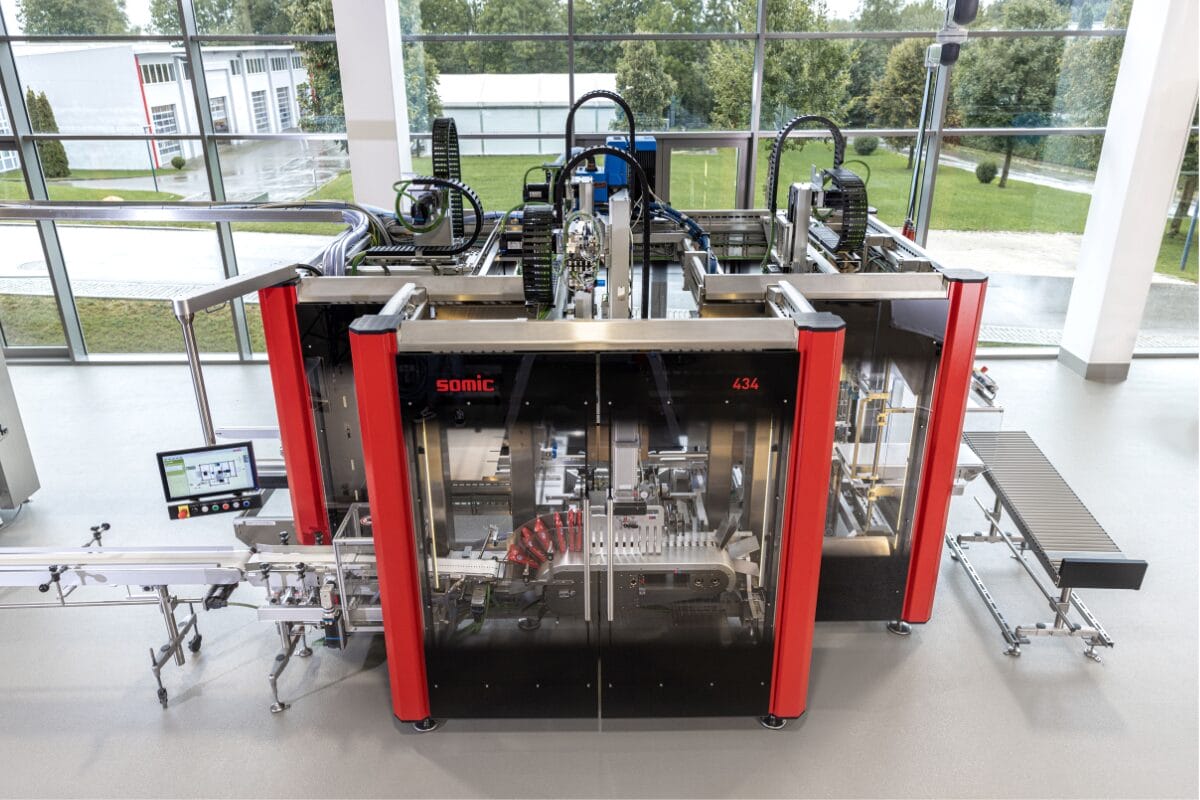

The next steps in the success story follow on seamlessly: Somic 404 for the first time in modular design from 1996, Somic 424 with improved technology and a new machine design from 2009 to on the current development status of the Somic 434 since 2023 with a narrow linear floor plan and a platform concept.

Developments in format changes

In the early days of the company, all format changeover operations were still manual, but modern technology offers users of the Somic 434 a fully automatic changeover process controlled from the control panel. Since the first carton erector, performance has changed from the hourly to the minute category. 500 chocolate bars per minute, 360 bags of powdered drinks per minute, 300 aluminium trays per minute, 500 biscuit rolls per minute: A new performance record is possible with every product and format.

The consistent consideration of savings potential when designing the carton cutting and packaging formats is particularly valuable. With its own in-house plotter and product-appropriate cutting, the company has been able to minimise costs in discussions with customers since 2016. customised packaging solutions using a practical example.

New possibilities

Flexibility for new carton formats, other grouping requirements or product formats: This is essential for customers when purchasing a new packaging machine. Since the early 2000s, all questions relating to machine flexibility have been an essential part of customer support. Between five and 20 formats are stored as standard in the customer-specific processing programme. With this number of packaging formats, many customers come for many years of operation. Just recently, a supplementary module for levelling the contents in the primary packaging was produced for a machine that is more than 20 years old in order to pack a new product in this machine. And if the existing format set is not enough? Then Further format parts customised for the new packaging requirement, so that the existing machine can continue to be operated.

Since 2011, such customer enquiries have been bundled in the „Retrofit & Upgrade“ (R&U) department with a team of experts who know the model history down to the last detail. With many years of service, ranging up to 19 years the employees' knowledge database back into the history of the machine. Well over 200 orders per year are processed in the R&U department.

From the drawing board to simulation software

While machine design was still a real manual job on the drawing board when the company was founded, the team realised a complete cultural change from 1990 onwards: with 2D drawing programs and, ten years later, 3D drawing programs, the design team always used the latest technology in design. The Visualisation of the machine by integrating the individual components from the library of the programme bring massive advantages for the presentation of the machine to the customer and for communication in the internal order processing procedure.

Another quantum leap was made in 2012 with the development of control programmes for end-of-line packaging machines. The Somic RealSource simulation is a Linking the original machine software with a 3D programme and shows the real motion sequence in the packaging machine. This allows the function of the software to be checked before the machine is built.

Over the course of 50 years, the control of the machines has undergone a similar development: A simple control panel with buttons is all that is needed to operate the first Somic WA 17 cartoning machine in 1988. Production lists are mainly kept manually. By the time the company celebrates its 50th anniversary in 2024, no customer will be satisfied with on/off buttons. Human Machine Interface (HMI) is the standard for all operator actions on the machine.

Convincing concept for success

The decisive factors for successful development are clarity about the necessary changes and the willingness to quickly integrate the possibilities of new technologies into suitable solutions for the benefit of customers. This has characterised the history of the company to this day: The second generation with Managing Director Patrick Bonetsmüller has been continuing the success story since 2015. One fly in the ointment in the anniversary year is the Death of company founder Manfred Bonetsmüller in October 2024. This sad event sharpens the focus on what has been achieved so far and will also be an incentive to follow his visions and lead the company successfully into the future.