From 28 to 31 January, LoeschPack will be exhibiting an upgrade of the FHW-S at ProSweets in Cologne. The machine packs bars and tablets in flowpacks. The company is exhibiting in Cologne together with its sister company Hastamat.

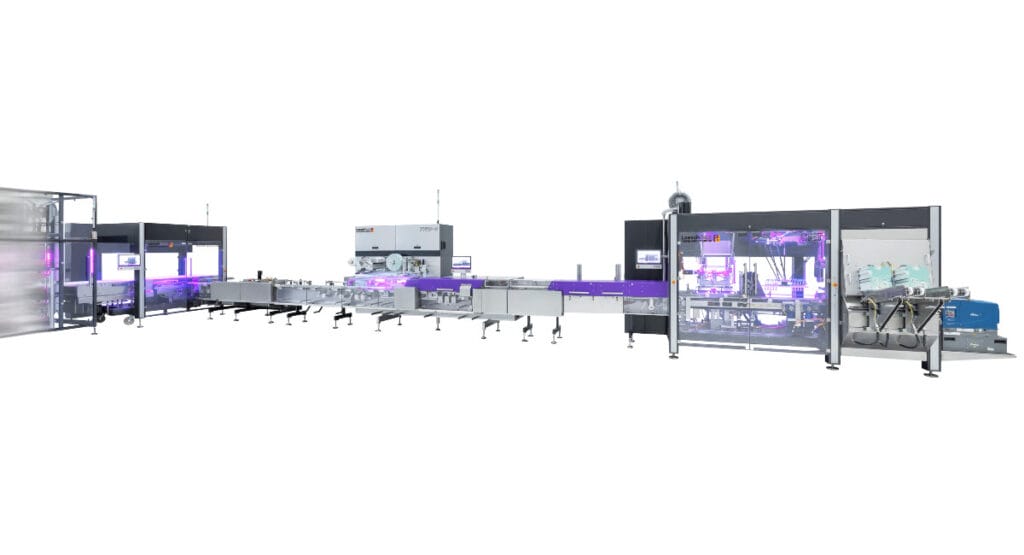

At the trade fair stand LoeschPack the trade visitors of the international supplier fair for the confectionery and snack industry. Innovative and modular bar packaging line - from buffering and product feeding to the finished packaged product.

„We are continuously developing our packaging machines and our broad portfolio. This enables our customers to pack their products even faster, more sustainably and more efficiently. We achieve this with a packaging process that is perfectly tailored to our customers“ requirements. True to our company motto > Packaging your ideas ..."

Olaf Piepenbrock, Managing Partner of LoeschPack, Hastamat and the parent company Piepenbrock

High performance, flexibility, sustainability and quality: the FHW-S horizontal flow-wrapping machine from LoeschPack's F-Series combines these characteristics. It is the centrepiece of the bar packaging line for production systems with a high degree of automation. Constantly undergoing further development, the machine manufacturer will be presenting the FHW-S at the ProSweets its high-performance model, which is characterised by an even Faster and more flexible working methods is what sets it apart. The machine packs up to 2,100 stick or tablet-shaped products at up to 205 metres of film per minute.

„In addition to its uncompromising performance, the FHW-S also impresses with its flexibility in terms of packaging material, format range and packaging shapes. The platform is designed for both classic and alternative packaging materials and can process both plastic and paper-based wrapping materials as well as laminates. Switching between materials is effortless at the touch of a button and the splicing process ensures smooth and highly efficient production even at full speed. Unwinding the film to the core reduces operating costs and waste. And all this with high packaging quality.“

Dr Ferdinand Schwarzfischer, Head of the LoeschPack development team at Altendorf

In combination with the upstream LOOP buffer system and the LOMATIC feeding and distribution system, the result is a unique packaging system that fulfils the highest demands.

Storey, gondola, belt or overhead buffers: LOOP buffer systems are specially customised to the Requirements of large production lines for bars, tablets and other confectionery products customised. With integrated buffer systems, LoeschPack succeeds in increasing production efficiency and regulating the production flow. The system is directly linked to the LOMATIC feeding and distribution system for all speed ranges. In addition to chocolate, the machine also processes Biscuits, waffles and muesli bars. Row by row, the LOMATIC feeds the downstream packaging machines at a speed of up to 190 rows per minute. From the Neapolitan to the 300 gram bar. The design is focussed on efficiency, precision, durability, easy cleaning and quick and easy format changeovers.

In the field of cartoning, the company will be presenting its newly designed, space-saving CMT system at the trade fair. It can handle up to Process 1,000 products per minute - with a maximum output of up to 200 cartons. The incoming products from the flow-wrapping machine are turned through 90 degrees by a turning device, slowed down and fed to the racetrack. The format can be easily changed. Regardless of whether the customer requires a high-speed inline version, a traditional 90-degree feed or a two-lane feed The CMT is available in versions that meet these requirements.

Source: LoeschPack

LoeschPack at ProSweets: Hall 10.1, Stand G030-H031

More news on the packaging of confectionery

Three applications, one solution

Judgement: No trademark protection for square Ritter Sport packaging

Dot meets sweet

Confectionery packaging: plastic-free for Christmas