Stäubli Robotics is presenting a comprehensive automation programme at the leading trade fair Automatica, including robots with and without AI, mobile platforms, forklift AGVs, digital solutions and software tools.

On the hardware side, the company has focussed on expanding its range to include mobile robotics solutions and is presenting three AGVs at Automatica, including the world's first cleanroom vehicle for use in aseptic environments. And on the software side, Stäubli is opening a new chapter in AI-supported robotics through a cooperation with Robominds.

AI opens up a new range of applications

In fact, the combination of Stäubli robots and Robominds AI opens up completely new possibilities. Intelligent robots are predestined for a whole range of new tasks, including in particular applications with small batch sizes and a high number of variants. The big advantage: AI robots can recognise, grip and separate articles in all variants. The constant programming and teaching of new variants is no longer necessary. Taking on completely new tasks is also quick and easy. All you have to do is select the right AI skill from the Robominds library - and you're done.

Logistics solution for the mail order business

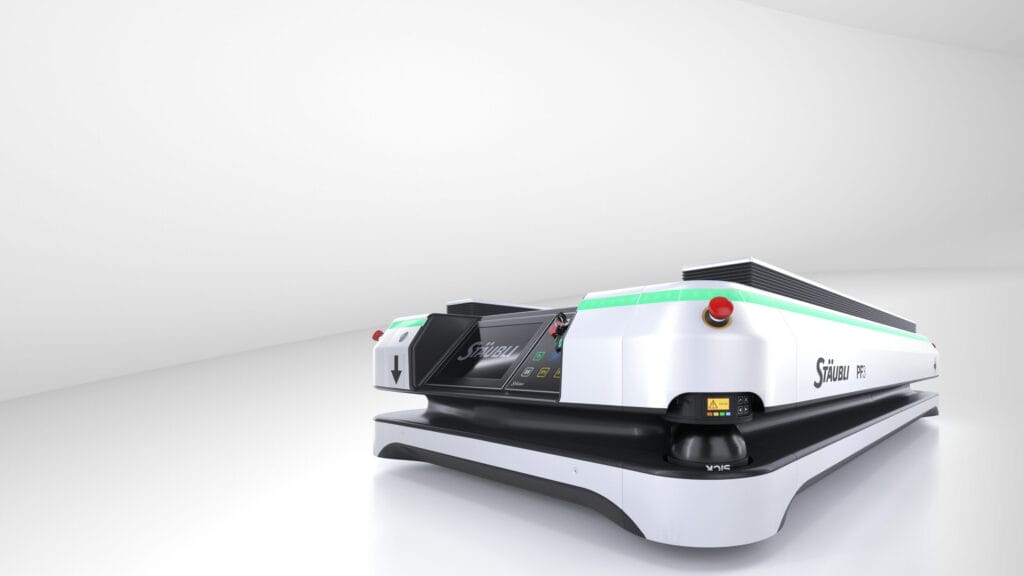

At the trade fair stand, Stäubli Robotics will also be demonstrating how the interaction of AI robotics, AGVs and control expertise can be used to solve a typical logistics task from the mail order business simply, quickly and safely. In the practical demo application, a PF3 mobile transport platform loaded with various shipping goods moves under a gantry with a TX2-160L ceiling-mounted robot. Thanks to AI, the six-axle truck recognises the goods on the PF3, It picks them up and sorts them for correct placement on conveyor systems for further internal transport. The mobile robot can communicate with the TX2-160L via Stäubli's fleet management system to ensure a safe process.

Mobile robots penetrate aseptic areas

In addition to the PF3 mobile transport platform, two other mobile solutions will be on display at the stand, including the FL1500 self-propelled counterbalanced forklift truck, which was developed in close cooperation with the PF3. Cooperation with Mercedes-Benz logistics planning was created. Built for use in confined spaces, the FL1500 is characterised by its compact design, which gives it excellent manoeuvrability and a very small turning circle.

„A real trade fair highlight is of course our highly innovative Sterimove platform solution for cleanrooms of all kinds. The fully encapsulated vehicle is the only one of its kind in the world that is certified for GMP class A/B/C/D sterile environments. This opens up completely new possibilities for users in the medical and pharmaceutical sectors.“

Peter Pühringer, Managing Director Stäubli Robotics Bayreuth

Simulate, commission, monitor and optimise

Of course, the software developers at Stäubli have also made a significant contribution to the holistic range of solutions, as can be seen in the 2025 version of the Stäubli Robotics Suite. Through consistent further development the software tool of yesteryear has become a complex, high-performance PC environment for smart production. Particularly noteworthy: The Stäubli Robotics Suite 2025 is now fully compatible with Siemens Process Simulate software.

The Scope digital solution at Automatica is also impressively updated. Never before has the seamless monitoring and optimisation of robot fleets has never been as easy as with this tool. It analyses the status and load of the robots in real time, detecting irregularities or creeping changes in the process before production quality drops, components are damaged or even failures occur.

Source: Stäubli Robotics

Stäubli at Automatica 2025: Hall B5, Stand 315