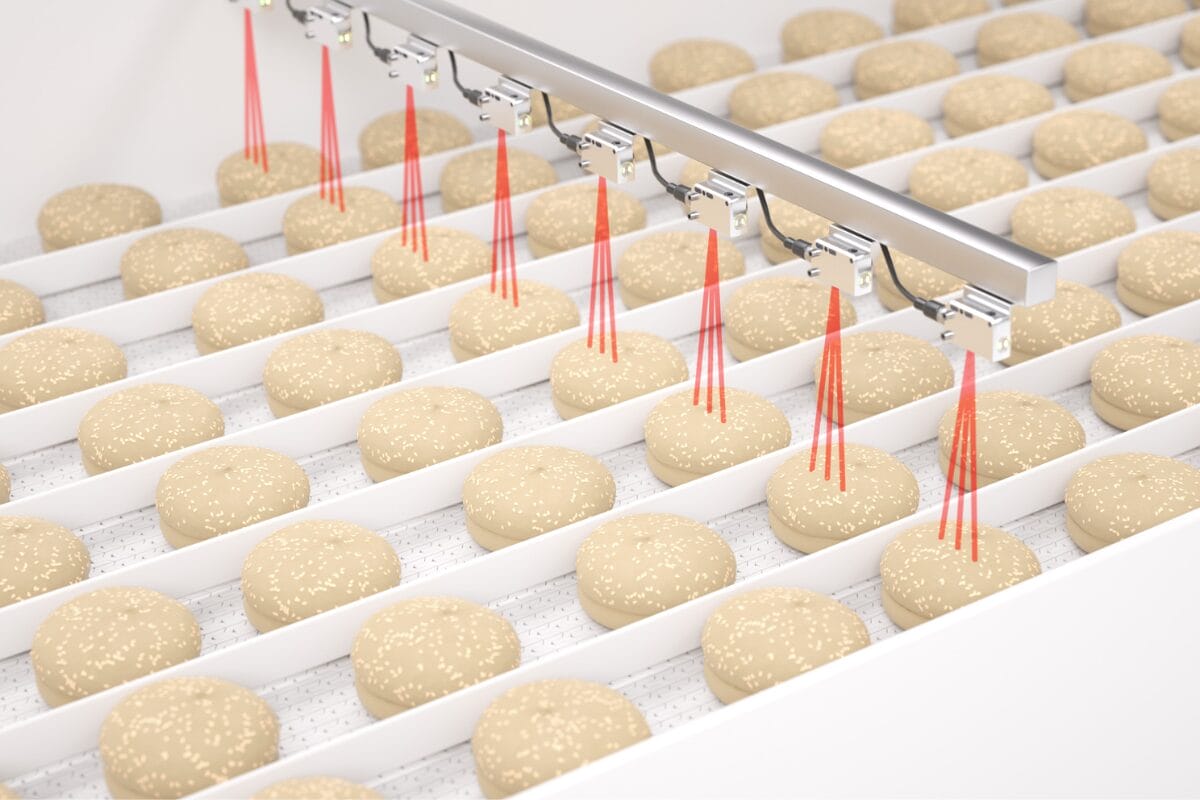

Hygiene-sensitive production and packaging processes place high demands on sensor technology. They must be robust, reliable and approved for direct contact with food. Leuze has launched two new sensor series in stainless steel housings specifically for these requirements.

Thanks to its smooth housing contours without mounting holes, the 33C series is suitable for Especially for applications in the food, beverage and pharmaceutical industries - even in plant areas with unpackaged products. The 35C series is designed for robustness. It is ideal for high mechanical loads and intensive cleaning processes. The sensors in the 35C series can also be used in the food industry.

Solutions for packaging processes

The two series each comprise diffuse sensors, through-beam sensors and retro-reflective sensors. The 33C and 35C series range also includes special solutions for packaging processes: These include Retro-reflective sensors for glass and PET detection, The new series includes sensors with background suppression for detecting small objects as well as dynamic reference sensors and through-beam sensors for film transmission. In the „small“ housing size, the new 33C and 35C series complement the stainless steel miniature sensors of the 53C and 55C series.

Quickly up and running with Power PinPoint LED

With the new 33C and 35C series, Leuze is offering sensors with Power PinPoint LED for the first time. With this light source technology, optical sensors can be easily put into operation and objects can be detected particularly reliably. This succeeds thanks to a bright, round and homogeneous light spot. It exactly reproduces the response behaviour of the sensor. The size, shape and homogeneity of the light spot remain constant over the entire working range. As an alternative to the Power PinPoint LED also devices with laser or infrared as light sources.

Absolutely tight

Sensors with plastic housings often have to be protected in harsh environments with specially manufactured and structurally complex stainless steel housings. Only then can they withstand the high hygiene standards and cleaning with high-pressure cleaners stand. This is not necessary with the stainless steel sensors in the 33C and 35C series. This reduces the complexity of the system, lowers installation costs and saves money. Protection classes such as IP67, IP68 and IP69K and certifications according to ECOLAB, CleanProof+ and Diversey confirm that the appliances also work reliably in wet areas and during intensive cleaning processes.

Smart communication

Another advantage: the two series are equipped with an IO-Link interface. This enables quick and easy parameterisation. System operators also receive diagnostic data via the interface and can therefore plan predictive maintenance.

Source: Leuze