Young boxes - Siemer Verpackung likes to flirt with the fact that two sisters run the company. The folding carton manufacturer also considers its technology, which it uses to realise preferably green packaging ideas, to be young. It has perfected its die-cutting process with a new flatbed die-cutter and machine optimisations.

„We play at the top of the market. Our technology has to support this,“ says Maren Grondey, Managing Director of Siemer Packaging GmbH, firmly. Folding cartons for (natural) cosmetics, food supplements, hygiene products, household goods and stationery - these are just a few examples of the high-end packaging that the company produces. „We love working for start-ups. They generally challenge our creativity and flexibility in particular. We are very happy to support companies that focus on sustainability,“ explains Maren Grondey. Together with her sister Laura, she took over the reins of the company, which has been family-run for more than 100 years, from their mother Renate in mid-2011 as part of the latest generational change.

Perfect timing

„It was time to set a new course for our punching process. Our SP 102 E flatbed die-cutter from BOBST, which was commissioned almost 20 years ago, was increasingly becoming a bottleneck,“ says Laura Grondey, looking back. „We kept looking at the products on offer from various manufacturers. BOBST has always been the market leader in flatbed die-cutting. From our point of view, nothing has changed in this respect,“ says the Managing Director, who is responsible for the technical equipment.

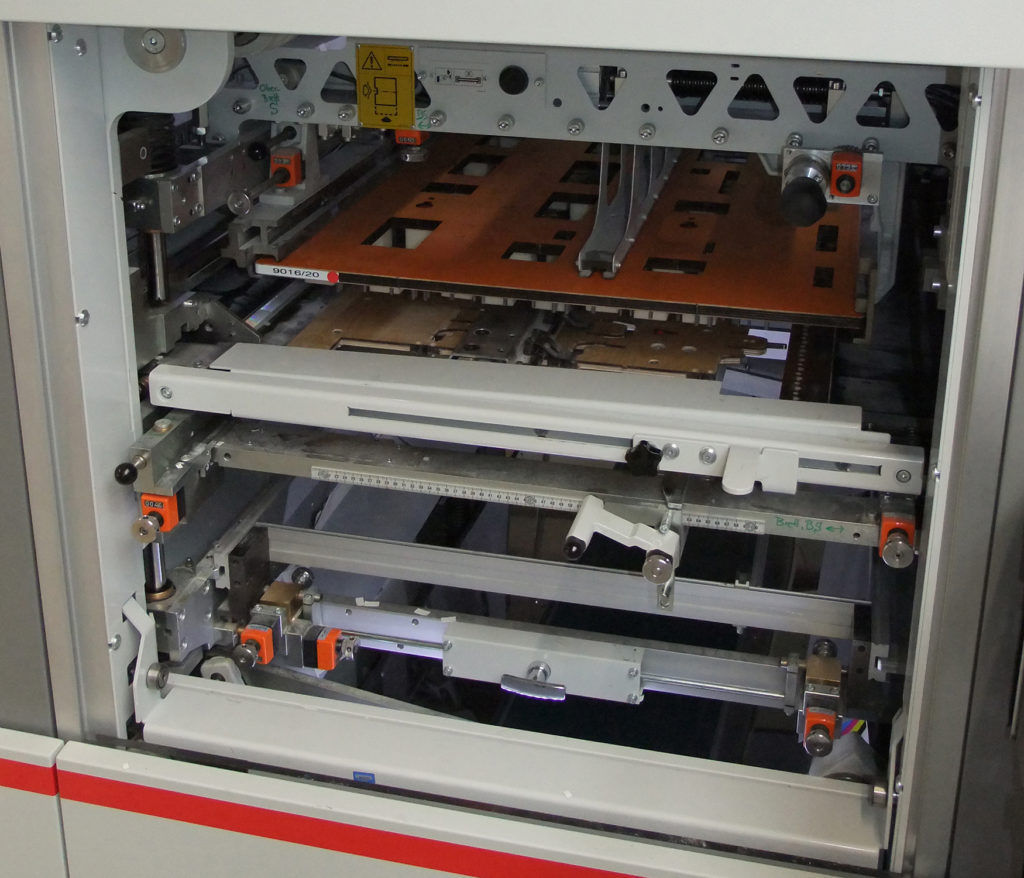

When the Swiss engineering company launched the NOVACUT 106 E, the time had come. Its high hourly output of up to 8,000 sheets per hour, its high degree of automation, its modern, clear design and its ease of operation combined with an attractive price-performance ratio were the ideal match for the packaging manufacturer's requirements.

At the same time, the automatic punching press offers a high degree of flexibility in processing different materials. The machine punches thin materials from 80 g/m with maximum reliability2 Basis weight, solid board up to 2,000 g/m2 and laminated corrugated board up to four millimetres thick.

Higher productivity and production reliability

With the NOVACUT 106 E from BOBST, Siemer Verpackung has taken the next step in flatbed die-cutting. „With this technology behind us, it is easier for us to promise and meet even the tightest delivery deadlines. This is particularly well received by our customers,“ says Maren Grondey, emphasising the importance of the significantly increased productivity in the die-cutting process. „Depending on the order, we now easily punch 7,500 sheets per hour with the machine. We are working on fully utilising its maximum output of up to 8,000 sheets per hour,“ adds Laura Grondey.

To achieve this, all factors in the punching process must interact optimally. Punching tool production in particular has become a key factor. Here, Siemer Verpackung relies on Hesse Stanzwerkzeuge from Alfeld, a company certified by BOBST as part of its tooling initiative.

The company booked several days of training from BOBST for its machine operators to bring their knowledge up to date. These training courses were tailored to the individual requirements of the operators. „The training courses were very efficient,“ says Maren Grondey, praising the experts from BOBST Meerbusch. „They gave our machine operators additional motivation.“

Fast order changes

Siemer Verpackung retools the new flatbed die-cutter an average of three times per shift. The machine operators also benefit from the high degree of automation of the die-cutter, particularly when setting up new jobs for the first time. For example, the automatic quick-clamping and locking systems, which can be operated at the touch of a button, support the fastest tool changes. The new, intuitive user interface with touchscreen also makes the machine operators' work easier. If errors occur during the process, they can see at a glance on the screen how and where they need to intervene.

No matter which materials are to be processed: They run smoothly and quietly through the die cutter. The even sheet transport is a decisive factor in the high reliability of this machine. And it helps to minimise waste. In combination with its energy efficiency, the new automatic die-cutter also supports the packaging manufacturer's environmental goals.

„We have not yet gone to extremes with the NOVACUT 106 E,“ says Laura Grondey, hinting that the machine still offers the company many options for the future. Today, it is harder than ever to predict what the market will demand in the future. That's why it's good to have the flexibility to process such a wide range of materials in-house.

Services guarantee process efficiency

At the same time as commissioning the new flatbed die-cutter, Siemer Verpackung had its SP 102 E technically upgraded by BOBST. Among other things, the company took advantage of the platen conditioning service. This involved removing oxidation from the platens, frames and plates of the die-cutter using a patented tool and special NSF-certified cleaning agents. Siemer Verpackung has always had its SP 102 E preventive maintenance carried out by BOBST as part of the Maintenance Plus service. This minimises the likelihood of unplanned machine downtime.

The same applies to the particularly versatile EXPERTFOLD 110 folding carton gluing machine from BOBST recently installed in Ronnenberg, with which Siemer Verpackung can pull out all the stops in folding carton production. Among other things, it is equipped with the CAPACITY FOLDER for the production of mailing bags with filling heights of two to 15 millimetres, the WONDERFOLD mobile rotary folding hook for folding flaps in the direction of travel and the PLASMA TREATER. This option improves the adhesion of adhesives on metallised, UV-coated, laminated and plastic packaging. „BOBST provides its customers with a wide range of options to get the last bit of efficiency, quality and flexibility out of their production technology,“ emphasises Maren Grondey.

The NOVACUT 106 E is connected to the manufacturer's Remote Service Helpline Plus. This has direct access to the machine control system via the internet and provides the packaging manufacturer with rapid technical support. With the productivity apps Remote Monitoring and Downtime Tracking, the company can in turn permanently monitor the process data and analyse the causes of any machine failures.

(Image: Siemer Verpackungen)

Siemer Verpackung purchases spare and wear parts via MyBOBST. „The portal makes it easier for us to create our orders. We also have an overview of when and why service technicians from BOBST Meerbusch have visited us,“ says Operations Manager Heike Kokott, emphasising two advantages.

In addition, the company's technicians can use the portal to conveniently find out which spare parts they need. Finally, orders placed via MyBOBST are delivered to customers free of charge if the value of the goods exceeds 500 euros. „We are also happy to take advantage of this offer,“ says Maren Grondey. The company has not needed any spare parts for the NOVACUT 106 E to date.

[infotext icon]Siemer Verpackung GmbH was founded in 1906 as Kartonagenfabrik Ernst Siemer in Hanover. Today, the packaging manufacturer with almost 35 employees realises smart ideas for high-quality packaging as a full-service provider for branded companies in a variety of different industries. Now in its fourth generation of family management, the fully equipped company based in Ronnenberg supplies customers throughout Germany and Switzerland, who in turn distribute their packaging to many parts of Europe[/infotext].