Many thousands of folding cartons, die-cut and glued packaging with high-quality flexo or offset printing, leave Mondi's plant at the Bad Rappenau production site every day. The different packaging formats and large production quantities place high demands on outer packaging and transport.

Corrugated cardboard products in a wide variety of designs with customised printing are part of the portfolio: Multi-part glued packaging ("shelf ready packaging"), complex die-cut and multi-point glued packaging, as well as wine cartons, fruit and vegetable crates and packaging for the mail order business ("e-commerce") are typical products from this Mondi site.

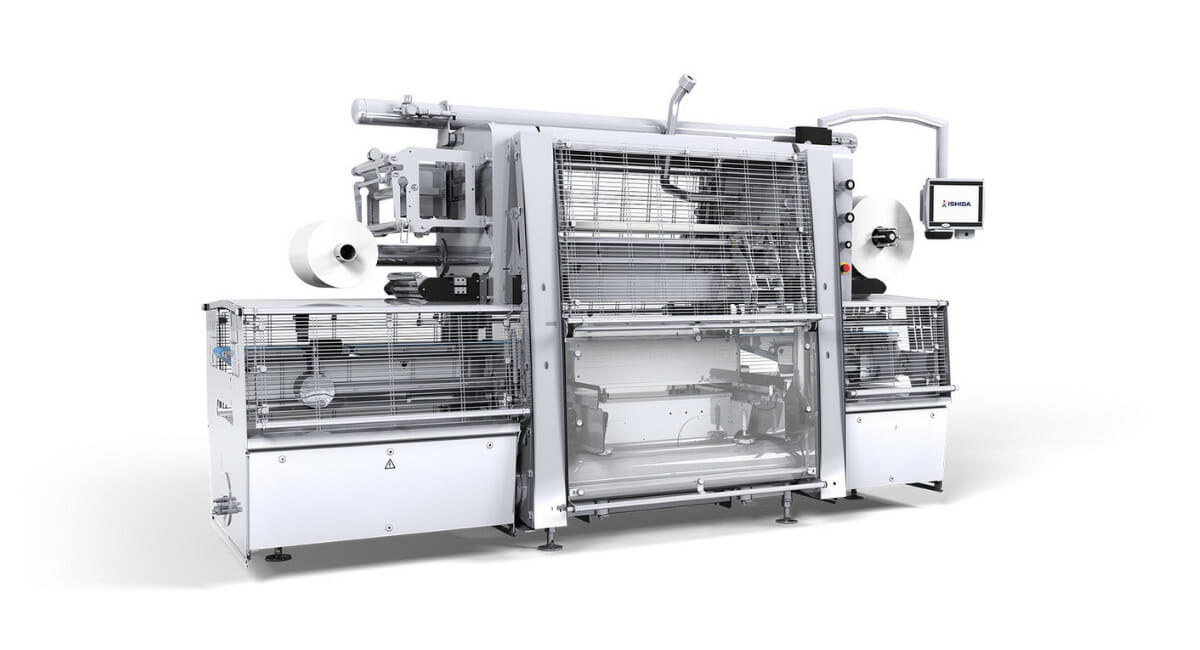

In one of Mondi's high-performance lines, a Bobst FFG618 inline machine glues packaging together along its longitudinal seam. For one Suitable strapping solution Mondi turned to the machine manufacturer Mosca. The company was able to convince the customer with a newly developed SoniXs UATRI-2 XT: Glued packaging are aligned fully automatically in bundles and strapped before palletising.

Special requirements

Corrugated board packaging must be transported through the processing machine safely and with minimal disruption. A Reliable strapping of the packaging bundles also guarantees the stacking quality and safe transport of the pallets to the customer. On the other hand, the strapping must not damage the products. The Gentle strapping is an important aspect for technology leader Mosca, which thanks to own production of the strapping can provide different strap widths and thicknesses and thus also prevent "cutting" into the product surface.

The machine manufacturer from the Odenwald region of Germany had already developed an application for a folding box gluing machine in advance. Semi-automatic solution for bundling of multi-point glued packaging was developed and delivered. In this project, Mosca impressed not only with its geographical proximity but also with its uncomplicated, prompt and solution-orientated approach and short response times.

Plant manager Marcus Mayr chose Mosca and the UATRI-2 XT with SoniXs unit, which is currently under development, to replace an existing unit: "We found it very interesting to use the ultrasonic technology introduced by Mosca in the High-performance application to use."

Strapping with ultrasound - cole performance

Traditionally, strapping machines seal strap material using a thermal process. The SoniXs unit developed by Mosca, on the other hand, relies on Ultrasound. "The strapping unit in inline strapping differs significantly from the common standard 6-SoniX strapping units," explains Michael Zimmermann, Head of Sales Systems DACH at Mosca. The UATRI-2 XT uses two standard units per machine. This design enables a Double strapping for narrow products.

"We developed a mirrored SoniXs unit for another customer project and recognised its potential for use in inline machines. We can now offer energy-efficient and extremely reliable double strapping. for the smallest products guarantee", explains the expert. In addition to these positive aspects, SoniXs models require less energy and energy savings compared to hot wedge machines. work more wear-free.

Fast and flexible

High performance, as required at Mondi, is no problem for the newly developed UATRI-2 XT. Up to 30 parallel strappings per minute at a conveying speed of 1.6 metres per second and a package length of 600 millimetres. In order to fully utilise the machine's maximum performance, Mondi relies on two units as well as a Double dispenser. If one roll of tape is used up, the machine automatically switches to the second roll. The throughput widths of the UATRI-2 XT are 1,300, 1,600 and 2,000 millimetres, even with ultrasonic technology.

The folding boxes can be bundled into a single unit and strapped once or twice. The bandwidth of the longitudinally glued packaging ranges from 240 to 870 millimetres and requires quick adjustment of the strapping pattern.

"For different articles, the Strapping parameters saved like a 'recipe' and quickly retrieved via a reference number for future orders of the same type. This ensures a smooth changeover between orders," explains Mayr. In order to strap packages in very different formats, the side aligners can also be set up in the three steps "small", "medium" and "large" can be adjusted.

Bundle for bundle Quality

The UATRI-2 XT also carries Fully automatic for checking the packaging: Upstream quality assurance systems in the processing machine ensure that various Quality parametersThe quality of the product, such as the straight infeed of the corrugated board sheet, the folding quality (known in technical jargon as "gap" and "fishtailing"), the slit depth of the base and lid flaps and the quality of the glue application on the glued longitudinal seam are measured. Deviations from the product specifications are detected and transmitted to the machine via a signal.

After strapping, these bundles are automatically discharged via a ball chain conveyor. "This is important because we always want to deliver optimum quality to our customers," explains Marcus Mayr.

"ZERO-DEFECT" philosophy

Another particularly important factor in the decision in favour of the Mosca machine was the state-of-the-art safety technology, which is guaranteed by the approval of the machine by the BG ETEM employers' liability insurance association. "The "ZERO-HARM" concept is the most important pillar of our Mondi philosophy: "We come and go healthy," says Mayr. "With this machine, we are relying on a German manufacturer that meets high standards and realises the automatic adjustment of the formats well."

Reliable and innovative partner

In the course of the assignment at Mondi Mosca perfecting the machine to meet customer requirements. This concerned, for example, the adjustment of the rear product stops: Previously, this had to be done manually, but the two project partners are currently working on an automatic changeover.

Marcus Mayr is very satisfied: "We have always focussed on the Service from Mosca can count on. The project partners were reliable and quick to respond when problems arose. I also think it's very important that we can rely on a partner with its own belt production, so that any troubleshooting that may be necessary can be completed quickly." Marcus Mayr is also looking forward to further developments from Mosca. "I have come to know Mosca as an innovative partner who is keen to test. We will certainly take a look in the direction of Odenwald when we continue to modernise our lines."