The pharmaceutical industry is responsible for almost five per cent of global CO2-emissions. This makes them an important player in the fight against climate change. It is therefore all the more important that all stakeholders within the pharmaceutical supply chain contribute to defined sustainability goals. This also includes packaging and labelling manufacturers.

The EU Packaging and Packaging Waste Regulation (PPWR) sets ambitious targets for waste reduction and requires recyclable packaging and the use of recycled materials. Developing an efficient climate protection strategy is crucial for companies, to recognise their contribution to climate change and reduce their own greenhouse gas emissions. Innovative label manufacturers for the pharmaceutical industry are already offering their customers sustainable product solutions. Schreiner MediPharm, a division of Schreiner Group, is one of them.

Two effective solutions for reducing waste are recycling and waste avoidance. Schreiner Group has been collecting and recycling silicone paper waste in Germany for over a decade. Added to this are the Collection and recycling of plastic carrier material made from siliconised polyester (PET). A total of around 300 tonnes can be recycled every year.

In addition, the pharmaceutical expert offers its customers the opportunity to realise their Collect and recycle silicone and plastic backing paper to leave. This optimises processes and also strengthens the customer's sustainability profile.

From development to disposal

The development of sustainable labels starts with the design and choice of materials. This requires comprehensive expertise in label design, printing technology and materials. Because the new functional labels based on sustainable materials must be easy to process in pharmaceutical production and function reliably in the end application.

When designing the label, developers must place particular emphasis on sustainable material types, CO2-footprint and the recyclability of the product. Ecology and efficiency should also play a key role in production planning: with a focus on material efficiency and low pollutant emissions. These efforts lead to solutions that have a significantly improved environmental footprint at comparable costs and performance and also take social aspects into account in the supply chain.

Climate-friendly sealing solutions

Innovative closure seals from Schreiner MediPharm are based on high-quality Film material with a recycled content of up to 90 per cent. They therefore fulfil the long-term objectives of the EU Packaging and Packaging Waste Regulation. Because functionality and tamper evidence must be guaranteed, the development of such seals is a challenge. Comprehensive tests ensure that sustainable seals fulfil the following requirements in particular Transparency, printability and reliability of the first-opening indication offer the same performance as conventional solutions. The switch to sustainable upper materials leads to a CO2-reduction of around 28 per cent at film level compared to conventional material.

Environmentally friendly function labels

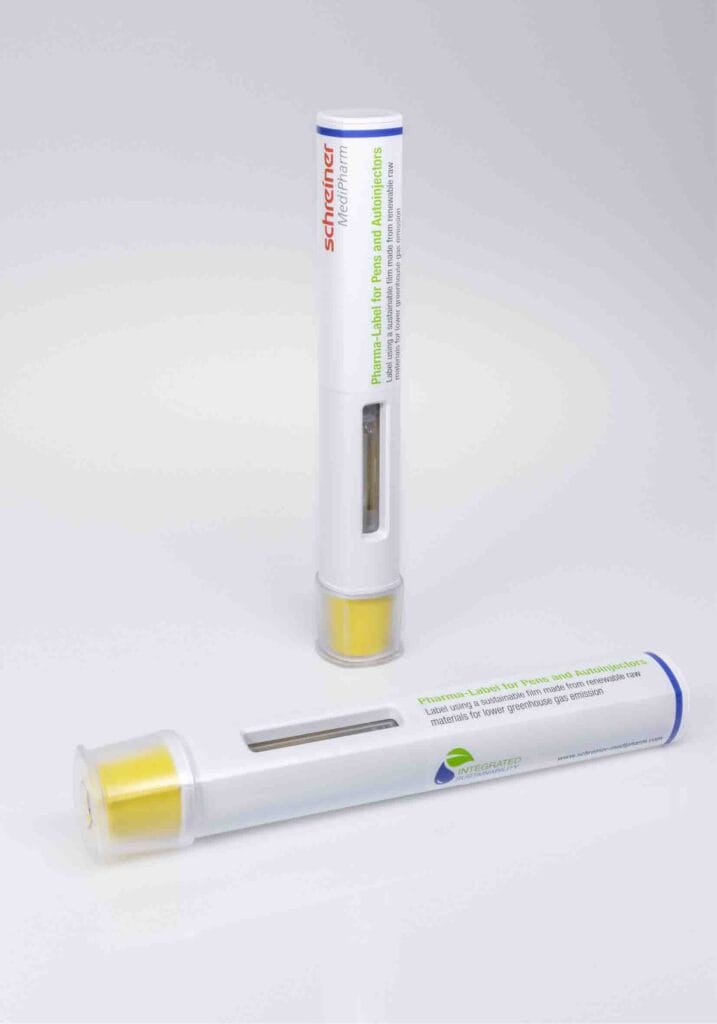

Examples of sustainable labelling concepts include a Pharma-Tac label for infusion bottles with integrated suspension bracket and removable documentation parts or a Auto-injector label for injection systems, with an anti-slip function. Environmentally friendly film materials made from recycled materials were used for both concepts.

Extensive in-house research and development tests prove that the new materials work just as reliably as previous ones, including load and drop tests in accordance with DIN ISO 15137. Adhesion, colour adhesion, print resistance and laser marking have been successfully tested. The new materials enable problem-free processing and guarantee reliable functionality.

The PCF calculation is carried out according to the cradle-to-gate principle, that all CO2-emissions from the extraction of raw materials to the dispatch of the product to the customer. This consideration also includes end-of-life scenarios.

Resource-saving needle protection solution

Needle-Trap, a needle protection system for pre-filled syringes, is characterised by a reduced ecological footprint. Compared to conventional needle protection systems, Schreiner MediPharm's solution has a compact design because the needle catcher is integrated directly into the label. Needle-Trap uses less plastic material and saves space during transport, storage and disposal. In addition to the lower environmental impact, this is also cost-efficient. An additional seal for first-opening indication can replace blister packaging.

Compared to conventional needle protection systems, Needle-Trap requires up to 76 per cent less space in the freight container, generates up to 76 per cent lower transport costs and reduces emissions during transport by up to 83 per cent. The label-integrated plastic catcher also contains Up to 50 per cent recycled pellets. This is one of the reasons why pharmaceutical manufacturers such as Pfizer, Leo Pharma, B.Braun, Sterinova and Kingfriend use Needle-Trap internationally.

Setting and achieving sustainability goals

Memberships and certifications help companies to achieve their own sustainability goals. One example is the Alliance to Zero, which was founded in June 2021 by eight companies in the pharmaceutical value chainSchreiner MediPharm, Dätwyler, Harro Höfliger, HealthBeacon, Körber Pharma, Schott Pharma, Sharp and Ypsomed. The aim of the alliance is to support the decarbonisation of the pharma supply chain and enable the market launch of net-zero pharma products by 2030.

Assessments by EcoVadis and emissions reporting via the Carbon Disclosure Project (CDP) help to check the sustainability of suppliers. EcoVadis evaluates companies in the areas of environment, labour practices, business ethics and sustainable procurement. Schreiner Group has a gold rating. CDP focuses on the environmental data of companies and takes into account all relevant emissions, including along the entire supply chain. The Science Based Targets initiative (SBTi) supports companies in setting science-based climate protection targets in line with the Paris climate targets. Schreiner Group is committed to both CDP and SBTi.

The calculation of the PCF is crucial for assessing the climate impact of a product. Schreiner MediPharm carries out these calculations in accordance with the Greenhouse Gas Protocol and the ISO 14067 guidelines in order to minimise CO2-emissions of a product and identify potential savings.

Future-proof action

The development and introduction of sustainable labelling for the pharmaceutical industry and the support of a circular economy are important aspects in the fight for sustainability. Labels not only play a decisive role in terms of Product and patient safety, but also contribute to Reduction of CO2-emissions to this. Through sustainable production practices, pure recycling, the use of recycled materials and, in particular, thanks to innovative sustainable product developments, packaging specialists such as Schreiner MediPharm show how this can be achieved, to continuously minimise the ecological footprint. Examples of sustainable production include, in particular, a geothermal project and the reduction of electricity-related emissions through the use of green electricity and photovoltaic systems at Schreiner Group's headquarters in Oberschleissheim.