As a Master's student at Stuttgart Media University, Lisa Scherer has developed an ecological packaging material made from grain husks that could replace expanded polystyrene (EPS). The patent has already been filed and the company is now ready to be founded.

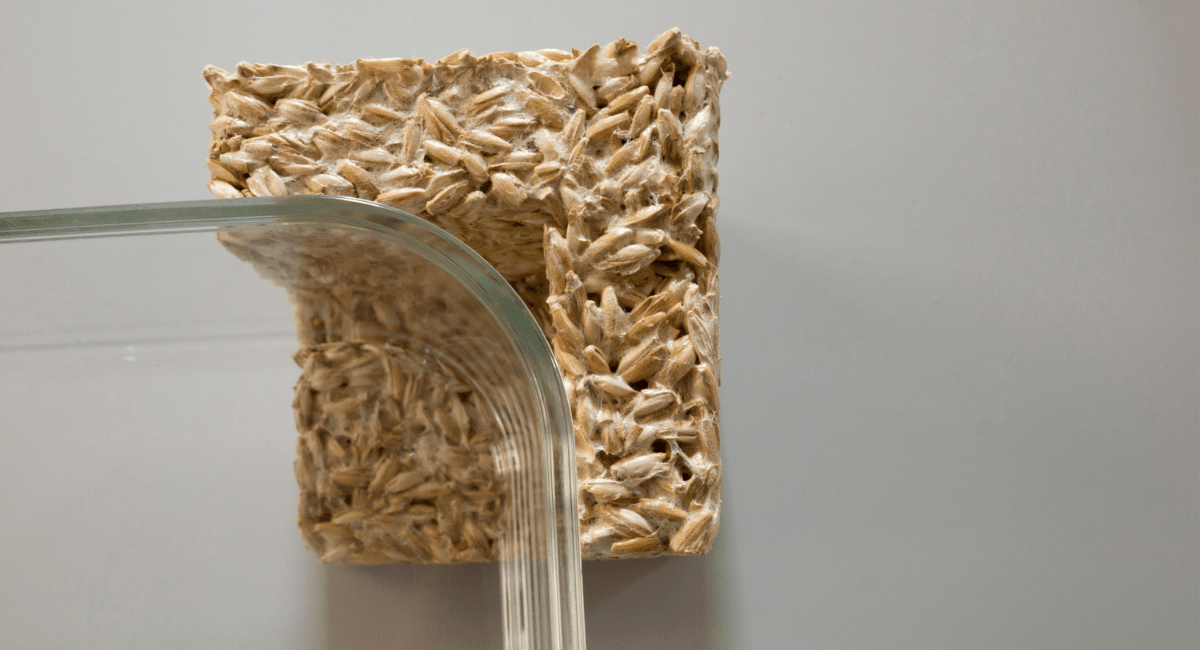

The new material consists of husks, which were previously disposed of as unused waste in grain processing. Due to the natural cavities in the husks, the new material has the following properties Good insulating and shock-absorbing properties. With the help of organic adhesives, it can be moulded to any shape and is completely harmless to the environment.

„We obtain the grain husks from regional mills. They are usually used as animal bedding or simply burnt. Our project helps to ensure that the raw material is utilised once again.“ Lisa Scherer, Proservation

After use, the sustainable packaging material should be easy to dispose of in the organic waste bin or home compost.

Packaging material made from husks on the way to market maturity

The material was created by Lisa Scherer during her Master's degree in Packaging Development & Management at the Hochschule der Medien (HdM) and was already the subject of her final thesis. Proservation is the name of the company she wants to set up together with three others.

Lisa Scherer's sister Sophia is also part of the team. The packaging technology graduate is responsible for project management, marketing and process development. Nils Bachmann deals with business management and market strategy, the start-up process and IT interfaces. He has a Master's degree in Business Informatics from the HdM. The team also includes Henning Tschunt, who has just completed his Master's degree in Sustainable Corporate Management at the Eberswalde University for Sustainable Development (HNEE).

Pilot applications and collaborations wanted

The young team has received an Exist start-up grant for the further development of the material and would like to use it to develop its product. ready for the market by February 2022 bring. The first step is to drive forward product and production development. Subsequently, suitable partnerships will support the development and testing of industrial production.

The team is currently using the university's infrastructure. „We are producing our first samples there and test various organic binders. We hope that we will then be able to implement a small packaging line in the autumn and produce an initial small series.“ The team is looking for sensible packaging applications for the initial product realisation. „Our material could initially be used in small, regional projects, for example as transport protection for wine bottles.“ The four have already aroused interest with their sustainable product, and the first enquiries have already been received.