Romaco will be presenting sustainable process, tableting and packaging technologies for the food, pharmaceutical, cosmetics and chemical industries at Achema 2022. These include a new aseptic liquid filling line.

Under the motto "Together towards a sustainable future", the Romaco his approaches for a more sustainable production and to reduce CO2-emissionsThe innovative process management of the technologies means, for example, that production times can be shortened, thereby saving energy and material. Space-saving design reduces the ecological footprint of machines and lines. And the packaging process as a whole can be made more sustainable through the safe processing of environmentally friendly packaging materials, for example for the production of paper blisters. In addition, all Manufacturer's machines available in a climate-neutral version and with energy monitors for sustainability reporting equipped.

The company will be showcasing a selection from its portfolio at the trade fair, including the Ventilus Pilot fluidised bed processor from Romaco Innojet, the KTP 1X and KTP 590X tablet presses from Romaco Kilian and the TP R Optima drum coater from Romaco Tecpharm. The Unity 300 blister line from Romaco Noack and the new Macofar E aseptic liquid filling line will be on show to demonstrate the company's line expertise.

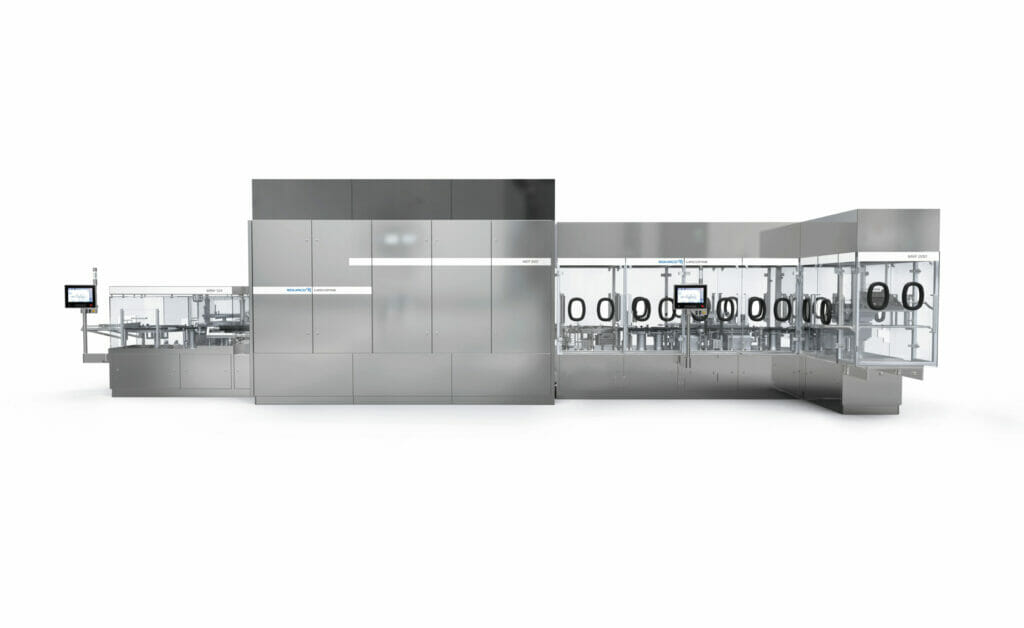

With the Macofar E series, the company offers a cost-effective turnkey solution for the aseptic filling of injection liquids into vials. The integrated lines each consist of a rotary washing machine, a depyrogenisation tunnel, a liquid filling and capping machine for tamping plus a flanging machine. Cartoning machines can also be connected if required. The technology fulfils all the requirements of the revised Annex 1 of the EU GMP guidelines for the manufacture of sterile medicinal products.

Overall, the Macofar E has a maximum output of up to 24,000 vials per hour. Depending on customer requirements, the line can be equipped with oRABS, cRABS or isolator technology. The filling machine's weighing system ensures 100 per cent weight control of the vials, including automatic adjustment of the filling volume.

The integrated Unity 300 blister line was designed for the lower to medium output range and fulfils all the requirements for more climate-friendly pharmaceutical production. For the first time, a sustainability monitor with intelligent stand-by functions, which monitors the energy and air consumption of the single-lane blister line and reduces the base load of the machine without having a negative impact on the overall equipment effectiveness (OEE). At less than eight metres in length, the monoblock is comparatively short, which reduces CO2-emissions are significantly reduced, especially in the clean room of the primary packaging.

Overall, the Unity 300 achieves a maximum output of up to 300 blisters and, depending on the cartoner, 200 or 300 cartons per minute. The blister line was equipped with Equipped with 100 per cent recycled Plexiglas panes and is also available in a climate-neutral version on request.

With the KTP 1X, Romaco Kilian presents the latest generation of its R&D tablet presses for use in the laboratory. The single punch press was developed as a All-in-one tool designed for research and development activities. It can be used for the compression of one, two and three-layer tablets as well as for tab-in-tab tablets. It achieves a maximum output of up to 1800 tablets per hour and pressures of up to 80 kN.

In addition, the KTP 1X is able to simulate all commercially available rotary presses, which makes it easier to carry out scale-up tests in particular. In addition to the production of clinical trial samples, the technology is also suitable for detailed error analyses and thus for process optimisation. Thanks to the rigidity of the machine, the displacement measurement of the punches in particular has been improved. The measuring accuracy goes hand in hand with low product consumption.

Source: Romaco

Further solutions from You can see Romaco at Achema in Hall 3.0, Stand B49.

More news about packaging machines

Automated packaging for changing shipping formats

Krones celebrates 75 years of company history

Traffic lights prevent bottlenecks

Confectionery: Flavour alone is no longer enough