PulPac has added a phone tray made of paper-based material to its portfolio, which can be used with the patented dry moulding technology of the company. Compared to conventional plastic or fibre-based alternatives, it is said to be have a significantly lower ecological footprint.

The Phone Tray Insert is a response to the growing demand for environmentally friendly alternatives in the packaging industry. With dry moulded fibre applications such as the Phone Tray Insert, users can opt for a Cost-efficient product with a smaller ecological footprint compared to conventional plastic or fibre-based alternatives.

„We recognise the importance of balancing sustainability and cost efficiency. This phone tray insert offers manufacturers and brands a cost-effective solution without compromising their commitment to the environment - a hallmark of Dry Molded Fibre.“

Sanna Fager, Chief Commercial Officer at PulPac

The Dry Molded Fiber product range includes standardised and commercially validated applications. So far The portfolio primarily comprises food-safe products such as protective lids, lids for coffee cups, lids for cold drinks, cutlery, bowls and dishes. The tray for smartphone packaging is now new.

In addition to offering production-ready applications with competitive unit costs and good sustainability features, PulPac offers, together with partners also turnkey production plants for different customer requirements. The aim is to bring about a change in the packaging industry in which sustainability is not just an option, but a fundamental principle.

SourcePulPac : PulPac

PulPac - More news

PulPac receives money for fibre packaging

SIG and Optima join PulPac

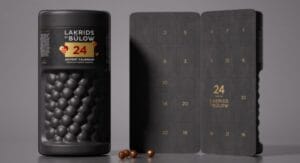

Advent calendar with dry moulded fibre packaging from PulPac

Fibre-based bottle closure