Cama and B&R have joined forces to tackle current challenges together. The companies want to combine their expertise in the fields of machines, technology and augmented reality to create highly innovative solutions.

Working in a high-tech niche market means overcoming the most difficult and demanding challenges. It means recognising your own value and identifying the positive scenarios that can drive the business forward. In this context, the „co-creation“ between Cama and B&R was created. The fusion of specialisations has created a mutual partnership between these two companies, enabling both to benefit from their combined expertise in terms of machines, processes and products in order to create highly innovative solutions.

„Finding the right partners is no easy task, because you have to have the same values and goals. Sustainability is our motto at Cama. Not so much in terms of environmental sustainability, as we do not produce environmentally harmful emissions and are not energy-intensive, but rather in terms of sustainability in the sense of longevity. We add value by maintaining shared values over time, and that requires a strong focus on people. At Cama, we produce machines, but we also produce people: We invest in our people to maintain the company in the long term. This is the only way to consolidate our market leadership. It is the people who make the difference, and all partnerships are built with people.“

Daniele Bellante, CEO of Cama

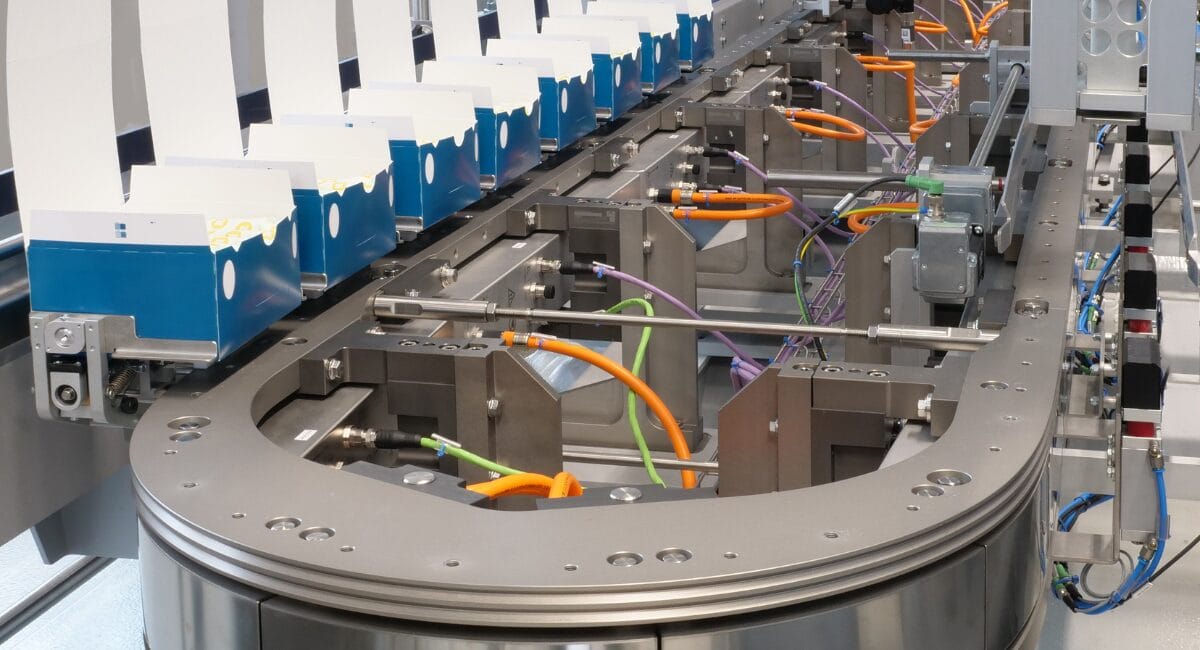

With B&R, we seem to have found a successful solution: an ergonomic, flexible and modular machine designed for the integration of the MTL Monoblock Top Loading System; this latest generation machine has a Transparent cover for maximum visibility and optimum hygiene. Intuitiveness is one of the key pillars of the design: this is essential as the product's target markets have different skill sets and potentially high staff turnover.

„This is a very interesting and complex solution. It also utilises augmented reality to access maintenance, retooling and spare parts that can be ordered directly via a tablet, which also enables predictive maintenance. The result is that this solution requires less human intervention and therefore reduces the potential for human error. Remarkably, this solution also saves time as the changeover time is reduced from 30 to 12 minutes! Our technologies offer real added value and our approach is holistic and customer-centred. This means that we pay close attention to the needs of our customers. And B&R's offering really helps us to deliver a customer-centric solution and successfully overcome certain challenges of the MTL Monoblock Top Loading System, namely to create a monoblock that can serve three or more upstream feeders for similar products with different synchronisations, and to manage the buffers automatically thanks to B&R's ACOPOStrak magnetic track system.“

Alessandro Rocca, Sales Group Director of Cama

The result is higher productivity with a smaller footprint. The solution makes it possible to decouple the process stations and thus optimise the product flow and cycle times. Processing times have also been optimised and the control panel has been simplified, making commissioning and maintenance quicker and easier.

„The challenge was the high throughput and the distance the products have to travel - up to 14 metres. In this sense, speed and dynamics become really important. We proposed ACOPOStrak in this case for several reasons: it is an extremely powerful magnetic shuttle solution: each shuttle can reach a speed of 4 m/s and an acceleration of 50 m/s2 . The system is modular, which favours the scalability of the machine; it also has a clean design that allows easy maintenance with tool-free shuttle removal. To achieve the customer's goals, we used simulation integrated into the B&R programming system to optimise the layout, number of shuttles and duty cycle. At this stage, the customer can make any changes even before the hardware is available. So we have a process that we call „co-creation“. It is impressive that the simulation delivers a result that corresponds to the real behaviour on the final hardware. The co-creation process is made possible by the combination of a variety of skills, and that's why it's ultimately the people who make the difference.“

Wlady Martino, B&R Global Industry Manager, Packaging

Annalisa Bellante, Vice President of Cama, confirms this: „We have always tried to be one step ahead, with a large R&D team of young people. We have a holistic view of the work that allows us to be innovative in our products, with a focus on the environment (we are increasingly developing sustainable packaging) and social policy. Our relationships with our suppliers are based on ethical principles and we take social responsibility by investing in society and engaging in the region. Corporate governance means acting globally and staying local, with a focus on gender equality. This is our way of working and it forms the framework by which we select our partners.“

This award-winning solution will be exhibited by our customer Edgewell at the upcoming PACK EXPO packaging show in Chicago: Cama and B&R have combined their expertise in research and development to create an impressive co-creation that tells a holistic success story.