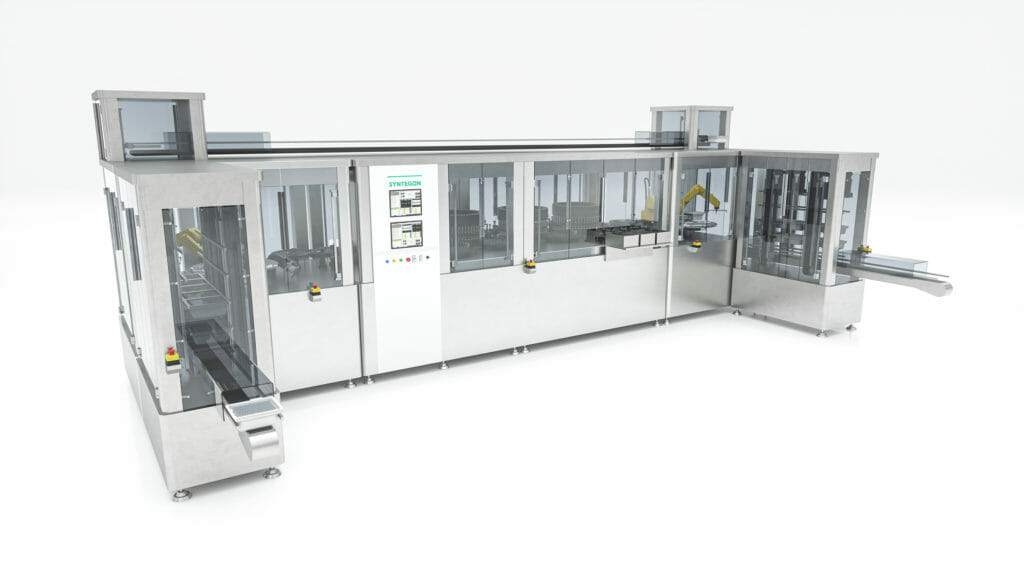

Syntegon has added a new member to the AIM 5 series: the fully integrated line for syringe inspection has a de- and re-nester and is also equipped with an artificial intelligence (AI) function as standard.

Earlier this year, Syntegon launched the first fully validated, AI-equipped visual inspection system. Now the company offers its customers the integrated AIM 5 syringe line with selectable AI as standard on. This is available for inspecting the flange, the plug and the cylinder.

The AI-based image processing system from Syntegon demonstrably increases recognition rates and reduces the false reject - especially for challenging products such as highly viscous parenteral solutions with air bubbles, which are sometimes difficult to distinguish from harmful particles.

„When drugs are administered intravenously, any contamination and particles in the product are unacceptable. Our innovative and fully integrated inspection line processes syringes with the utmost care and utilises AI to further increase inspection accuracy.“ Dr José Zanardi, responsible for applications and developments in visual inspection technology at Syntegon

Gentle processing and reduced footprint

The line is designed for particularly gentle processing: The robotic de-nester removes the syringes from the nest and places them precisely in a single-lane infeed, while the re-nester gently returns them after inspection. Throughout the entire process Glass-to-glass contact completely avoided, so that maximum product protection is guaranteed at all times. Thanks to the integration of de- and re-nesting, the line has a significantly reduced footprint. It can also be operated via a single, user-friendly interface (HMI).

Syringe inspection with robotics and AI

The inspection line, which Output of up to 18,000 inspected syringes per hour is based on the AIM 5 series from Syntegon, which is used by numerous customers worldwide. Its modular design consists of a pre-inspection module, a pre-rotation module and a main inspection module. Visual particle inspection is carried out using the proven Static Division (SD) technology. A module for high-voltage leak testing (HVLD) can be integrated for CCI (Container Closure Integrity) testing.

„Customers from all over the world have been relying on the AIM 5 for 20 years,“ says Zanardi. „In the new line, we have combined the advantages of the proven Inspection machine combined with state-of-the-art robotics and supplemented by AI applications expanded.“

Source: Syntegon