In the fully automated lines of modern packaging technology, technical brushes fulfil important key functions in many process stages. They fold, guide, convey, smooth and apply, and also prove to be extremely versatile players in numerous other cases. The decisive factor for their efficient use is always the selection of the best design and the right fill.

They fold cardboard boxes, apply labels, They smooth out films, slow down parcels and convey delicate containers and foodstuffs to the packing station. Today, technical brushes perform these and many other tasks in fully automated packaging technology lines. Time and again, they prove to be both efficient and flexible machine elements that can be used to realise numerous handling and kinematics for packaging, transporting and labelling very different groups of goods very easily and cost-effectively.

The fact that each brush system can usually be customised very precisely and with manageable effort to its task plays a decisive role here. The mere possibility of combining different carrier designs with different densities of trims made from many different materials to be equipped, opens up great scope for application-optimised adaptation and design of brush systems.

Kullen-Koti equips machine and plant manufacturers in the packaging, identification and conveyor technology sectors with innovative system and product solutions.

Starting from a wide range of products and with a clear focus on the customer's application, a renowned manufacturer like Kullen-Koti is therefore able to configure and provide a suitable brush solution for almost any packaging task - even at short notice.

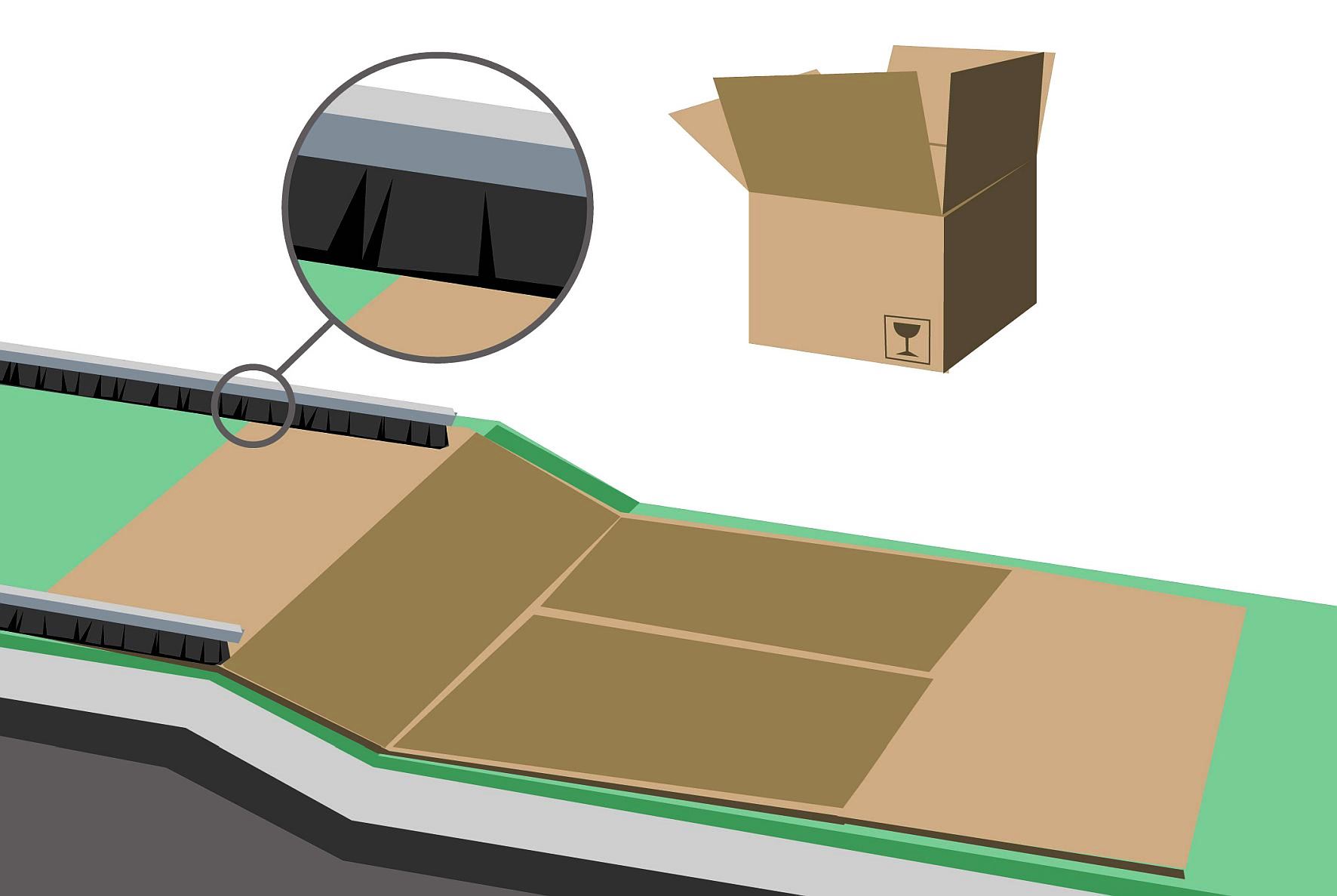

A large field of application in packaging technology, in which brush systems cover central functions as components of various devices and systems, is the mechanical processing of cardboard packaging. Here, it is mostly strip, spiral or roller brushes that fix and unfold the cardboard boxes delivered as flat folded products in fully automated throughput processes and erect them into ready-to-use outer packaging. In other versions, brushes of these designs are used after the cardboard packaging has been filled, as soon as the self-adhesive sealing strips and labels precisely applied and pressed on have to be transported. And to ensure that the parcels do not end up next to the conveyor belts on their intralogistical journey to dispatch, they are slowed down - where necessary - by brush plates and kept on track by brush strips.

Gentle promotion of sensitivity

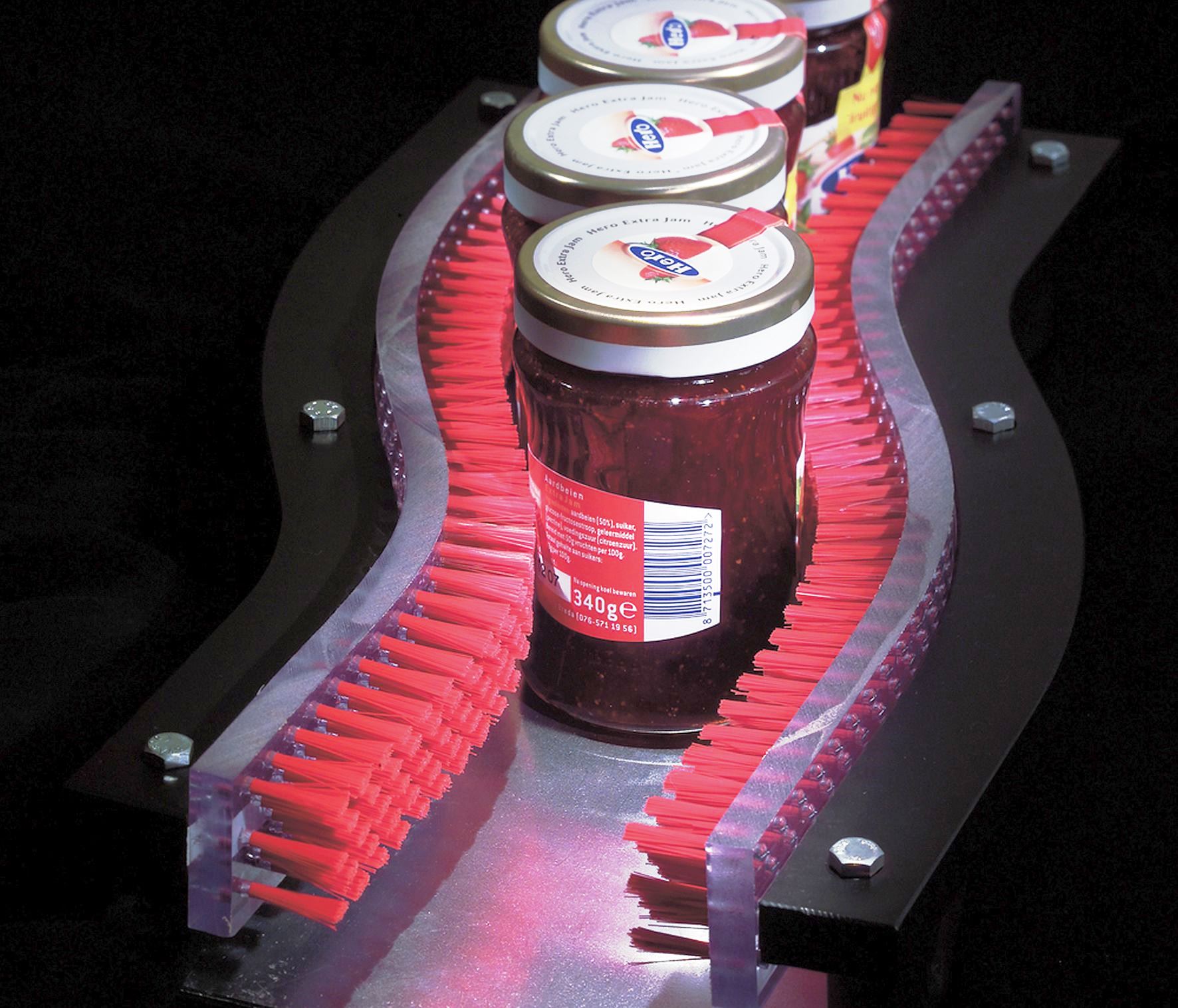

Technical brushes are also used in many other areas of packaging technology for the application of labels and conveyor technology tasks. For example, when fragile glass containers need to be labelled and then guided safely through the automated process from filling to delivery. Or when fresh, thin-skinned foodstuffs need to find their way into the transport packaging particularly gently and „unharmed“. Here, technical brushes play a key role in the truest sense of the word. For example, there is hardly a better solution for the delicate conveying of many types of fruit and vegetables as well as eggs than intelligently designed roller brushes with a spiral-shaped filling of particularly soft fibres.

Technical brushes are also indispensable in the processing of packaging films. Here, for example, high-quality brush systems from Kullen-Koti ensure precise winding and unwinding of the aluminium or plastic film from the coils, as well as controlled stretching and smoothing when packaging goods. A further process stage of film packaging, which is also covered by Technical Brushes, is the removal of static charge from the ready-to-ship packaging. In the manufacture of electronic and microelectronic products, this is usually one of the last process steps before delivery.

Partner of the mechanical engineers

When designing and configuring brush systems for packaging technology, a large number of of decisive factors.

- Which brush type is generally best suited for the specific task?

- What dimensions must the base body have? Which material, geometry and density should be selected for the trim?

- Are there any special requirements with regard to peripheral speeds, feed forces or the infeed process?

- Is the brush system used in a dry, damp, hot or cold environment?

- What service life is required?

- And how short or long are the maintenance intervals?

The Kullen family business was founded in 1913 and has developed over the decades into one of the leading international manufacturers of technical brushes. It has been part of the Dutch Koti Group since 2012 and has been trading as Kullen-Koti GmbH ever since. The company is headquartered in Reutlingen. Andreas Bruhn has been Managing Director since 2014.

Kullen-Koti's product range includes a large number of different designs and variants of technical brushes. As a manufacturer, OEM supplier and tool supplier, the company serves all industries and exports to over 74 countries. Kullen-Koti representatives and sales offices can be found all over the world.

[/infotext]Source: KULLEN-KOTI GmbH