Italian manufacturer IMA Spa is now using a hybrid drive system from Yaskawa. The company has switched from a mechanical to a fully electronic system.

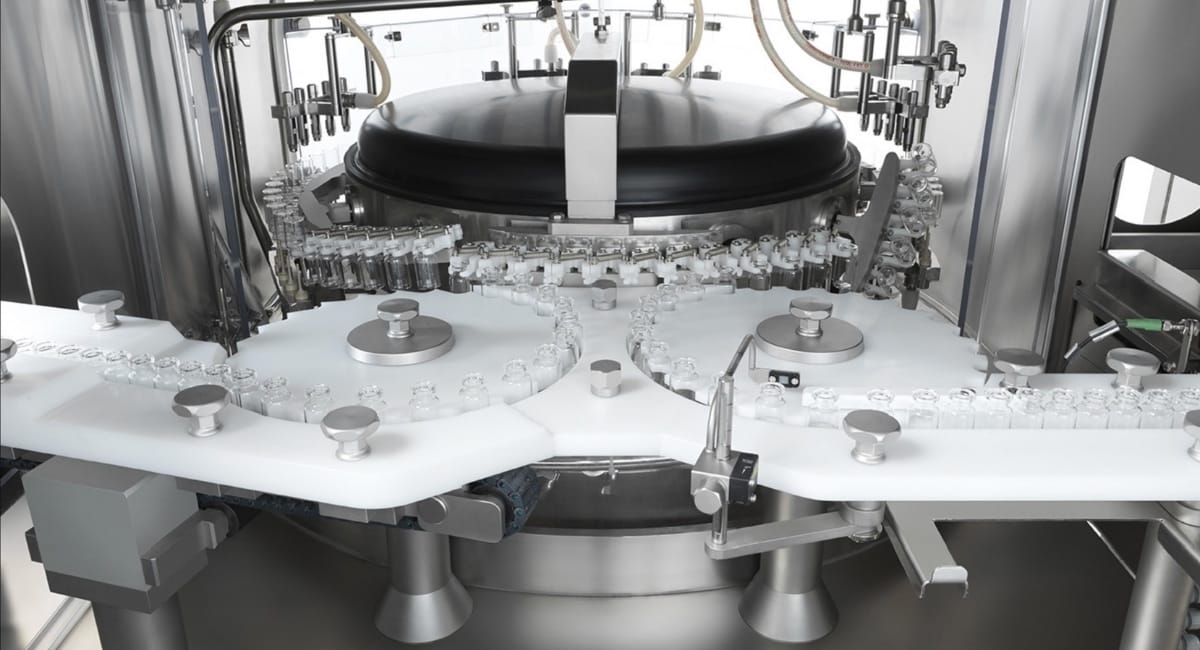

For almost 60 years, Italian manufacturer IMA S.p.A. has been developing and producing machines for processing and packaging pharmaceuticals, cosmetics, food, tea and coffee. The company has now upgraded the standard module of its VEGA series of multi-format rotary filling machines for sterile ampoules and vials with the addition of a hybrid drive system from a mechanical to a fully electronic systemFor the basic functions of the machine, transport of the bottles and management of the cleaning trolley, the mechatronic subsystem of the axis control consists of the MP3300iec machine control with Sigma 7 motors and drives from Yaskawa.

The project involved a major challenge: a A non-digital, non-real-time subsystem should be integrated into a digital real-time control system. be realised. The conversion of the VEGA series required the use of two special motors to lift the carousel, which were neither manufactured by Yaskawa nor equipped with a Yaskawa digital interface and therefore could not be managed directly by the selected control system. As a further challenge, the external 2-motor drive system is equipped with an incremental encoder, so it was a mechanical configuration with a vertical gantry. It was necessary to manage the adjustment during machine start-up, the management and correction of possible mechanical deviations during the normal cycle and in the event of an emergency stop.

Of the various solutions, IMA opted for the Control of the external system via special streaming of movement data, generated by a virtual axis in the Yaskawa controller. The solution not only proved to be robust and reliable, but also made it possible to Savings on components and cabling. During the tests to examine the tolerance of the streaming solution, an attempt was made to overload the PLC of the Yaskawa controller with a dozen additional virtual axes in electronic cams, several FOR_TO cycles and several subroutines. The result was excellent: The PLC did not exceed 60 % of its computing capacity, confirming that the PLC's real-time management and multitasking behaved exactly as expected.

„Yaskawa's motion control system not only proved to be powerful in terms of hardware and software, but was also designed to ensure the durability and resilience of the end product thanks to the predominant use of standard parts. In addition, the solution is environmentally friendly due to its high performance, which enables a lower energy footprint.

Maurizio Lodato, IMA

Source: Yaskawa