Stronger consumer brand loyalty, shorter processes in the supply chain and integrated safety aspects on packaging: these are the benefits for brand manufacturers of the latest generation of digital printing. The T1100S digital PageWide web press from HP, which is currently being installed in the Thimm Group's print division, opens up a whole new dimension in the field of digital printing.

Michael Weber, Head of Marketing Thimm Group, talks to packaging journal about the prospects opened up by this new digital printing technology.

pj: Mr Weber, how can this technology help to strengthen consumer loyalty to brands?

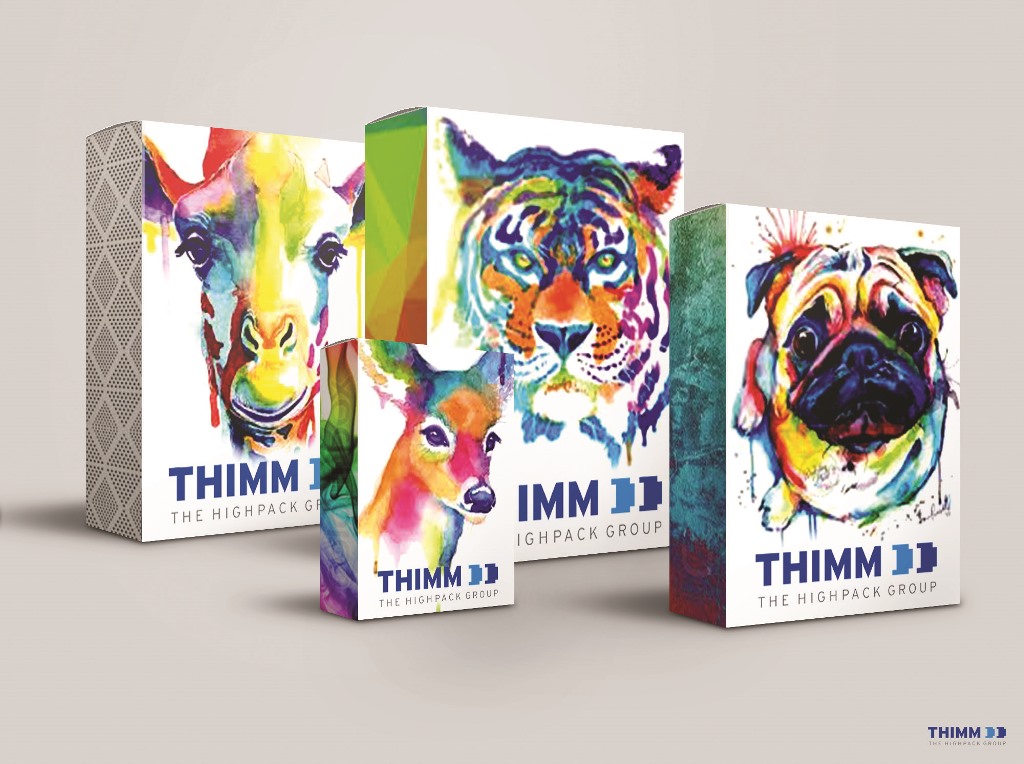

Michael Weber: Our customers are always looking for ways to position their products in bricks-and-mortar stores, but increasingly also in the mail order business, in such a way that they are stand out from the competition. Imagine if you, as a brand manufacturer, were able to address consumers personally via corrugated board packaging in the future, as we already know from personalised labels for soft drinks or chocolate spreads. Also customised advertising on shipping parcels or advertising with relevant content on product packaging are conceivable. Television packaging, for example, could show changing motifs from the most popular films. Fast print image changes with shorter delivery times are not a problem, so that current developments and a stronger Interlocking the packaging with other marketing measures, for example on social media, can be taken into account at any time. I can also very well imagine exclusive, limited editions - i.e. the serialisation of products and seasonal campaigns.

pj: What is the technology behind it?

Michael Weber: The so-called Multi-lane printing architecture (MLPA). This is the option of dividing the paper rolls to be printed into individual webs. This allows different jobs to be printed next to and behind each other on a preprint roll. Several very short or short runs can be placed in the queues and produced together without any intermediate preparation.

pj: What does this mean in view of the ever-shorter product life cycles? Does this mean that response times are getting shorter?

Michael Weber: Exactly. Products can be introduced to the market much more quickly, as the Preprint process significantly shortened can be realised. Test productions, the production of small quantities for field research or the equipping of test markets are possible without incurring plate costs. The highlight: other printing processes can be simulated using digital printing and thus combined in a cost-optimised way depending on the print run. This makes it possible to switch between digital and conventional processes at any time. Most spot colours can also be simulated. There are typically colour variations in conventional printing. We do not have these in digital printing. This enables us to achieve a constant colour tone and optimally implement the customer's corporate design in the rollout

pj: What restrictions are there with regard to formats?

Michael Weber: Almost none. Even very large formats up to 2.8 metres wide and almost any length can be printed in offset quality with a resolution of 1,200 dpi. This is particularly important with regard to the Display production enormous advantages. A display casing, for example, can be printed in one piece. As a result, there are no annoying adhesive edges later on. In addition, one work step can be saved in further processing.

pj: What is the issue of security all about?

Michael Weber: Each packaging can be equipped with a unique identity that fulfils different functions during the sales process: Invisible security features or originality features protect the brand from counterfeiting and misuse, for example. Other labelling features make it possible to identify the goods in the track the entire cycle. Another added value that this technology offers.

pj: Is the use of this technology limited to certain product groups?

Michael Weber: If you are referring to the migration of mineral oil, I can reassure you. HP's PageWide T1100S web press uses water and pigment-based CMYK inks. These inks are designed to meet the legal and industry standards for paper-based food packaging with indirect contact. They are therefore ideally suited for use in the FMCG sector.

pj: Is digital printing replacing conventional printing processes at Thimm?

Michael Weber: No, this technology complements the unique mix of different printing processes within the Thimm Group and is suitable for small print runs as well as for orders of up to 50,000 square metres. With the options available to us, we will be able to provide our customers with even more customised, better and more flexible support in marketing their products in future.

pj: When is it best to use which printing process?

Michael Weber: In addition to the print run, the criteria for selecting the process are of course the quality, the need for personalisation and individualisation, the costs and the lead times. You have to look at this on a case-by-case basis, work out the key points in dialogue with the customer and do the maths. You can't give a generalised answer.

pj: How great is the potential for digital printing in the corrugated cardboard market?

Michael Weber: Around 70 percent of corrugated board packaging sold in Germany is currently printed, a good 22 percent of which is printed in three or more colours. Only just under one per cent is digitally printed. I am sure that there is Great potential.

pj: Where is digital printing heading?

Michael Weber: In my opinion, industrial digital printing will play an increasingly important role in the coming years. Not only because of the many possibilities already described, but also because this technology will have a lasting impact on the process and generally promotes digitalisation in all processes. We want to play an active role in shaping this development and utilise the resulting opportunities. [infotext icon]

Thimm - Always one wavelength ahead

The company recognised back in the 1950s that packaging could also be an advertising medium. Three-colour direct printing was possible at the time. In the 1970s, Klaus Thimm developed a revolutionary printing process together with the company's technical director at the time: ThimmColor®. It took the advertising possibilities of packaging to a new level of quality. With the so-called Conprinta belt technology paper can be printed very flexibly and in any size with up to eight colours. For decades, no competitor was able to imitate this patented process. The classic transport packaging developed into high-quality, sales-promoting packaging, the benefits of which were quickly appreciated by the up-and-coming discounters. The two engineers thus pioneered the still growing field of multi-coloured pre-printed corrugated board packaging.

Since then, Thimm has continuously expanded its printing expertise and today offers the market a unique mix of technologies for packaging and display printing: From various processes of Flexo preprint, about the High Quality Postprint (HQPP) and classical Flexo direct printing until Offset and Digital printing. With the installation of the world's largest and most modern printing press for digital preprint at Christiansen Print in Ilsenburg am Harz, the company is once again setting standards for the further development of this exciting market. Measuring 11.5 x 34 x 5.5 metres, the heavyweight weighs in at 115 tonnes. The investment volume amounts to around 15 million euros[/infotext].