Toolink, the latest digital solution from Bobst, shortens changeover times by connecting mould, machine and processes. This provides packaging manufacturers with support when they need to deliver smaller orders quickly.

The Connection of the tools to the punches is a step towards Bobst's vision of shaping the future of the packaging sector. This novel solution represents the new standard for efficient and agile carton processing. By utilising digital technologies and connectivity, packaging manufacturers will be able to work more productively.

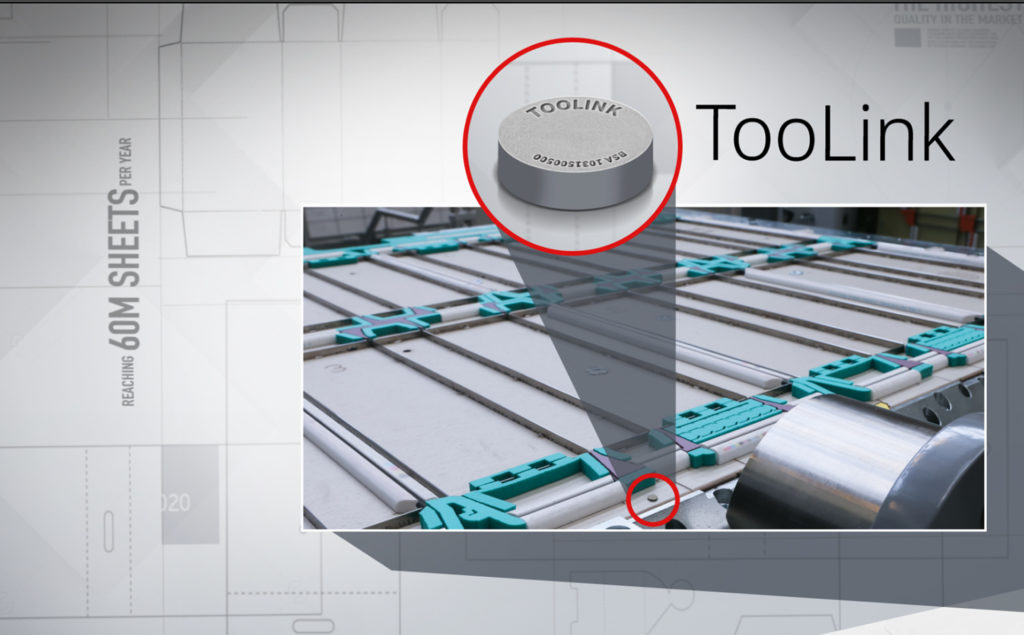

Short changeover times thanks to Toolink

TooLink simplifies job changeover by automating job management. This saves time for the operator and eliminates the risk of human error.

„Customers keep telling us in discussions that the downtime between two orders is still too long. This costs valuable production time. We recognised the opportunity to develop a digital and automated solution to solve this problem. The result was the development of TooLink.“ Alex Volery, Head of the tool department at BOBST

A Secure data chip is incorporated into every cutting die and creates an ID for each tool. As soon as the tool is inserted into the machine, the chip is read and the production-ready job is automatically transmitted to the machine with the correct alignment and settings. The operator only has to make two clicks on the punching machine's HMI. This saves time when retooling repeat jobs and avoids possible operator errors when entering the job.

The tools prepared for TooLink are provided by BOBST-certified cutting die manufacturers built. According to the company, this ensures perfect quality and compatibility of the tool with the punch.

All players connected in the future

„This is the first phase in our development of TooLink technology,“ continues Alex Volery. „We are working intensively on it, develop new value-added services as well as solutions for tool connectivity. The future scenario envisages that the various players will be connected, tool and order management will be done remotely and access to tool data will provide more detailed insights. These digital solutions will enable better decision-making in the future and offer more control, automation and efficiency.“

All new BOBST die-cutters in 106 format are TooLink-capable. In combination with Matic Plus, the time saved when retooling repeat jobs is 15 minutes on average. This gives packaging manufacturers additional production time and flexibility.

Source: BOBST