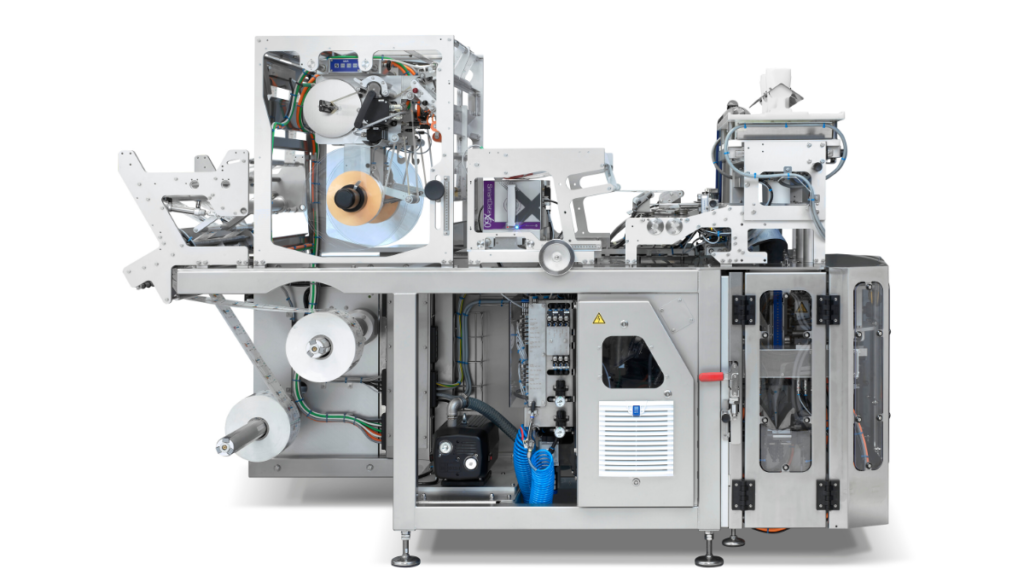

GEA launches its new vertical packaging machine SmartPacker TwinTube in Europe. The machine has been redesigned as a modular system with increased functionality.

The further developments in the field of sealing technology reduce operating costs and energy consumption. For the Bag production can be both Plastic as well as functional paper can be used.

The Packaging machine for pillow bags is a Continuously operating, vertically aligned machine, which is suitable for packing small foods such as sweets, nuts and dried fruit and other snacks in various sizes for on the go. The machine is Part of a complete packaging process with upstream and downstream devices that are operated in dry production. It works with two parallel moulding tubes and achieves a Combined speed of up to 500 bags per minute (with a weight of 10 to 18 g each).

It is also possible, A different film roll for each tube so that Bags of different widths or designs can be filled at the same time. A new function of the machine is the integration of the jumbo roll, that makes it possible, Film rolls with a weight of up to 100 kg for long production runs - this increases operating efficiency.

„The new TwinTube has a modular design, This means that customers can easily add new options and expand their machine, which extends the life cycle of the system. In addition, we have improved user-friendliness through the Introduction of tool-free adjustment options which enable shorter changeover times and error-free machine set-up - including the printer, labeller and vertical sealing unit. With these new updates, we are able to fulfil our customers“ requirements in terms of automated process control, reduced operator dependency, increased uptime and operational efficiency," explains Martijn van de Mortel, Product Manager Vertical Packaging at GEA.

Automatic web guiding control

The new SmartPacker TwinTube is also equipped with a Automated web tracking equipped. If the film deviates from its path, for example due to changes in the film roll, the machine reacts immediately and adjusts the direction of the film, without the need for manual adjustment. This ensures the quality of the resulting bags and avoids downtime at the same time.

Reinforced sealing for more flexibility

The new SmartPacker has a new jaw locking mechanism, a Optimised heating unit and a Vertical rotary sealing unit, which ensures robust packaging performance and excellent tightness of the pack seal. The new jaw closing mechanism offers more than three times the sealing force of the previous method and can apply 6000N. This enables the use of thicker films or films with different properties in relation to the sealing requirements. Thanks to the more stable suspension of the longitudinal sealing unit and the reproducible and precise positioning by spindle and ruler Shorter changeover times for format or film changes possible.

Simple labelling, operation and maintenance

The new GEA TwinTube is optionally available with a new, fully integrated GEA TiroLabel unit, which makes the machine even more compact in the factory. The Special labelling unit delivers a speed of up to 180 labels per minute with a width of 150 mm and achieves millimetre precision when placing the marking. The Label roll has quick-change operation, which means that it can be changed in seconds with minimal downtime.

Source: GEA