„I sold the first labels to Daimler at the beginning of February.“ With these simple words, company founder and namesake Heinrich Hermann later described how it all began in 1906. Today, HERMA is a leading specialist in self-adhesive technology with more than 1,000 employees.

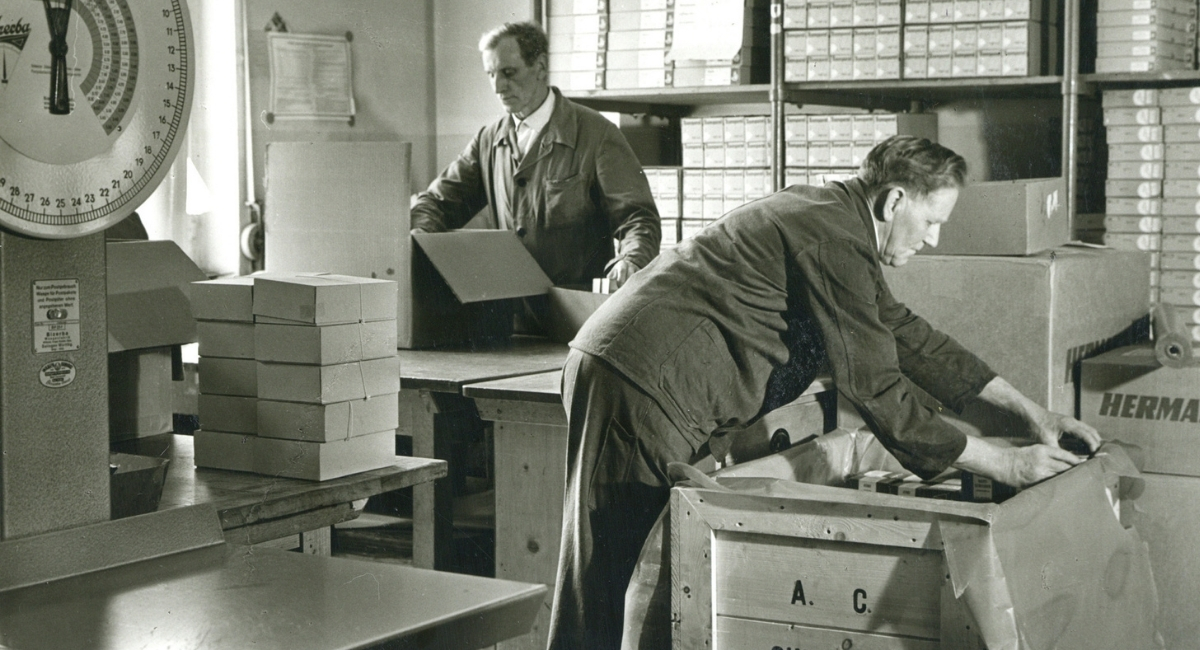

Just a few weeks before the „Daimler coup“, the Heinrich Hermann He set up his own printing business: with a high-speed press, a cutting machine and a perforating machine, all bought second-hand for the very considerable sum of 6,200 marks. He was always on the lookout for Improvements, He constantly developed new products and even tinkered with the necessary production machines because they were not available to buy as he imagined them. In many cases, he applied for design protection and patents.

The result of this origin

Almost exactly 115 years after its foundation Herma with adhesive materials, labels and labelling machines on a comprehensive range of products that is almost unique in the world. Expertise in self-adhesive technology to fall back on. At its headquarters in Filderstadt, the company brings together disciplines as diverse as paper and film processing, printing technology and mechanical engineering under one roof. The company has just invested over 100 million euros in the construction of a ultra-modern production for labelling machines and another labelstock plant. The two new production facilities went into operation in 2019 and 2020 respectively.

Masterplan until 2040

Both production facilities are located on the site that Herma only acquired in mid-2015 in the immediate vicinity of its headquarters. The investments made are just the first stage of a master plan for the 80,000 square metre site, which will extend until 2040. „With the gradual realisation of this master plan, we once again have the opportunity to secure the company's growth at this location over several generations,“ says the Managing Directors Sven Schneller and Dr Thomas Baumgärtner.

Herma already employs well over 1,000 people, who together generated a turnover of 364.4 million euros in 2019. HERMA has its own subsidiaries in England, France, the Netherlands, Austria and the USA; the export ratio for the company as a whole is stable at 60 per cent, but significantly higher in the two divisions of adhesive materials and labelling machines: The company enjoys an excellent reputation worldwide.

The triumph of self-adhesive technology

Curiously, Heinrich Hermann, of all people, did not live to see this development. When he died in 1939 at the age of just 69, self-adhesive, i.e. Labels with a pressure-sensitive adhesive are still unknown in this country. Rubberised labels were still used, which had to be laboriously moistened. But under the leadership of the company founder's two sons, Werner and Heinrich Hermann Jr, this changed soon after the war.

At the beginning of the 1950s, they noticed how the „supermarkets“ began their triumphant advance in the USA and correctly surmised that this trend would reach Germany: It is only a matter of time before this trend reaches Germany. Therefore Labels for price labelling The adhesive is needed that can be applied quickly, i.e. self-adhesively, and that adheres to as many different surfaces as possible without any problems.

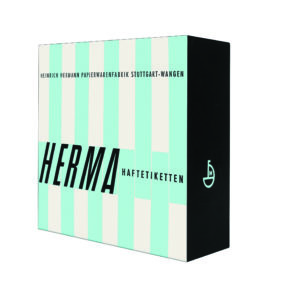

Self-adhesive labels become a bestseller

However, the idea was not so easy to realise. This was because the adhesive material, the „raw material“ for it, was initially difficult to procure in the quality required. Without further ado, Herma began coating paper webs with the appropriate adhesive itself and to self-adhesive labels to process.

As they were the pioneers in this field in Germany, the start was difficult and arduous. An important step for Werner and Heinrich Hermann jun. was to develop the production machines themselves. After all, the company founder had done the same at the time. Their commitment and perseverance paid off.

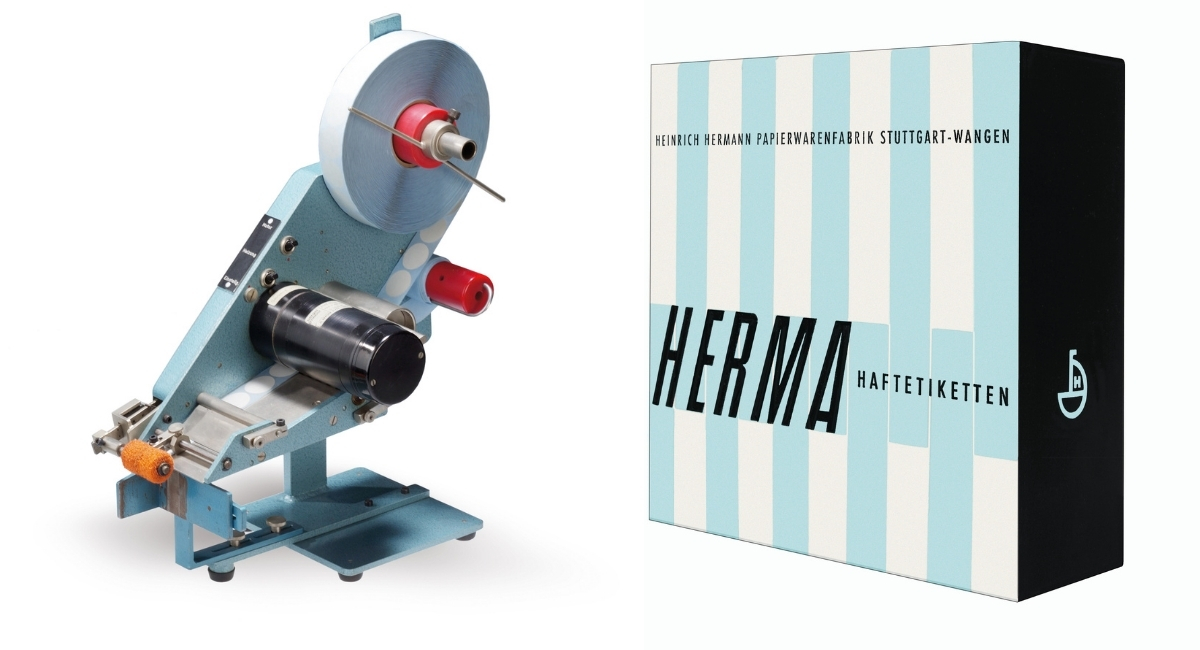

was developed in 1960 (Image: Herma)

Rapid development

However, one prerequisite for their mass use was the ability to apply them quickly, precisely and reliably to millions of products. So what could be more obvious than to combine the product knowledge gained to date with the company's own experience in mechanical engineering? After several manually operated devices, Herma developed The first electrically operated label dispenser in 1959, a year later, the „ancestor“ of modern labellers. Meanwhile, the company's own adhesive material proved to be so good and so popular that it was not only used for the company's own labels, but was also sold to other label printers.

From 1950 to 1976 the company's turnover increased thirtyfold. Today, the three divisions operate independently of each other on the market. This makes the company as a whole both flexible and extremely crisis-proof.

The courage to break new ground

However, the most important basis for the company's continuous growth is and remains Innovative thinking and action. Today, Herma is an international innovation leader in adhesive materials. The main focus here is on combining paper and film materials, adhesive, backing material and silicone at very high speeds and with extreme precision. With the entry into the revolutionary Curtain Coating, the curtain coating, and later as a pioneer in multi-layer technology, the company has set standards.

Multi-layer technology in particular has helped to open up new possibilities for label printers and users around the world and the best growth opportunities for Herma. This is because labels made from adhesive material with multi-layer adhesive systems can now combine properties that previously required expensive speciality adhesives, if solutions were available at all. These include, for example, very good adhesion even under extreme conditions and yet the possibility of subsequent, uncomplicated, residue-free wash-off, which is the decisive step for many recycling processes.

Efficiency and cost-effectiveness

The series production of labellers and complete labelling machines can be combined with a high degree of variability in application. It enables the experts to produce large quantities at the highest quality level and at the same time cater to the needs of very different industries.

Whether Pharmaceuticals, food or consumer goodsThe efficiency and cost-effectiveness of entire production lines depend on the reliable labelling of large quantities at high cycle rates. One outstanding example is the Herma 500 labeller, which is unique worldwide thanks to its combination of high performance and comprehensive connectivity, maximum flexibility and optimum operability.

Bundled specialised knowledge

Although the three business units operate independently, Herma benefits greatly from the combined specialised knowledge in self-adhesive technology. Rarely has this been as tangible as with the InNo-Liner system, for which Herma won the German Packaging Award in the Sustainability category received. It is probably the first liner-free labelling concept that really meets the requirements of shipping and logistics centres. This allows huge amounts of material to be saved on shipping labels.

In the most important shipping nations alone, around 100 billion shipping labels are currently produced every year. Until now, this has meant thousands of tonnes of document paper that had to be disposed of at great expense. The InNo-Liner system puts an end to this. Users are particularly impressed by the simplicity of the system, which consists of a combined activation and dispensing unit and a special adhesive material. The activation unit for the initially non-tacky adhesive is purely water-based. This means: no solvents, no heat and no other agents with various undesirable side effects. And the label user is practically Free choice of label paperIt does not require a silicone layer and therefore allows great freedom in pre-printing.

A solid foundation for the company's success

The reinvention of the label, this „game changer“ - the energetic and hands-on company founder Heinrich Hermann would have been delighted. Today, Herma has 29 shareholders. They are all fourth generation descendants of Heinrich Hermann. However, the family withdrew completely from management back in 1982. Instead of the principle of „family in the company“, for almost 40 years Herma has therefore applied the principle of the strong corporate family, which is united in its basic attitude, seeks close proximity to the company, but leaves the operational side to the best external management.

„Even today's family shareholders are always concerned with creating a sustainable basis for the company's success. This has a lot to do with sustainability in the broadest sense,“ explains Managing Director Sven Schneller. „And this means that the family is still an important anchor in turbulent times.“

This article is in the packaging journal 8/2020 published