At Anuga FoodTec, Ulma Packaging will be showcasing solutions for optimised and efficient packaging processes in the food industry. These include a high-performance tray sealing machine.

„Anuga FoodTec is the international meeting place for the food industry par excellence. It is the ideal platform for us to present our high-end machine technology. All the solutions we show at the trade fair are centred around the needs of the user. Our fully automated lines are particularly interesting for the food industry - for more efficiency and full control in the packaging process.“

Thomas Blümel, Ulma Managing Director

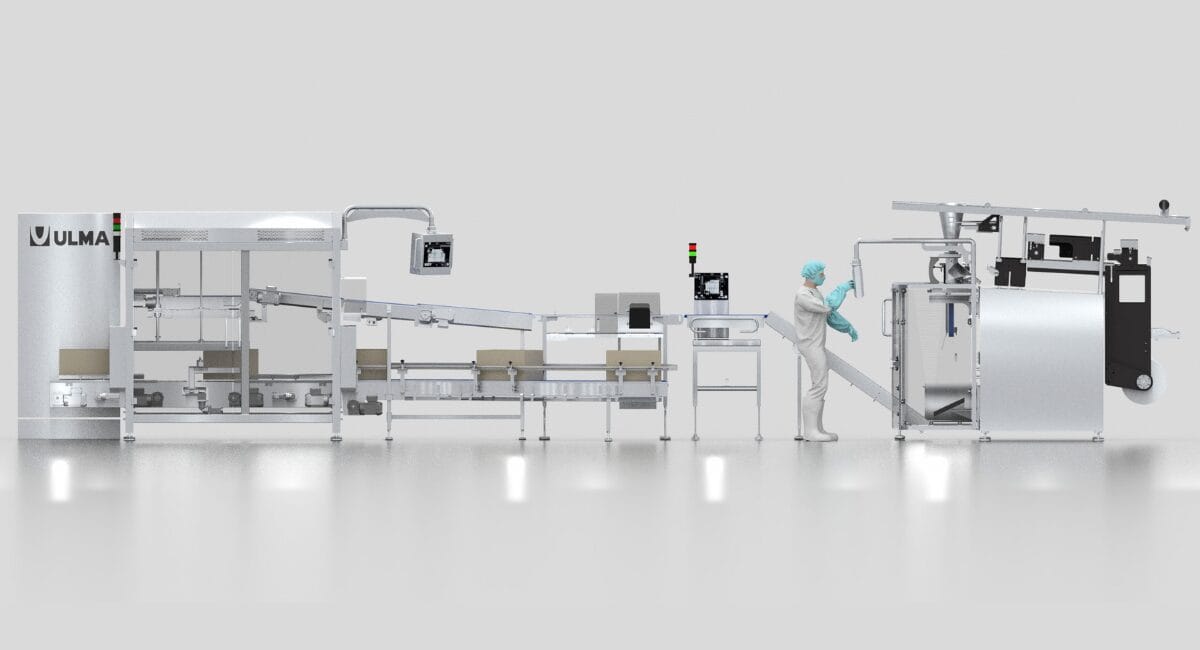

Ulma shows on the Anuga FoodTec 2024 his Packaging line for tray-sealed packaging of fresh products. The high-performance tray sealing machine scores points not only for its automatic loading and packaging, but also for its innovative control system via the Ulma Line Control System. This allows all phases of the process to be efficiently controlled and monitored from a single central point.

More sustainability through less packaging material: this is possible when packaging minced meat with the skinless flow-wrapping system (HFFS). Ulma will also be presenting this in Cologne, together with one of the leading manufacturers of meat portioning and mincing lines. With the horizontal packaging machine from the FM series, the company is following the European market trend, Continuously reduce packaging material.

The company will be exhibiting a line with the VTC 840 vertical packaging machine and an automatic gravity cartoner. With its wash-down design, the VTC 840 is suitable for use in the food industry. A special feature of the vertical bagging machine is the Tight bag technology for bag volume optimisation. It is compatible with various types of sustainable films. This enables optimum pack sizes to be achieved, which not only saves on logistics costs, but also on storage and transport costs. Another feature of the machine solution is the SealFlex system for Reduction in maintenance costs, as a quick jaw change is possible. The TFS 200 S, a thermoforming machine for SKIN applications, will also be on the stand. It is designed for Processing of various materials such as mono-material films, laminates or cardboard designed.

For the Packaging of slices and portions in the meat and dairy industry Ulma will be exhibiting several product lines at Anuga FoodTec 2024 that can be used to fully preserve products until they are consumed. Such packaging solutions include the TFS 700 high-performance thermoforming machine and the FM 500 horizontal flow-wrapping machine. The company will be exhibiting the FM 500 horizontal flow-wrapping machine with the LEAFSHRINK format as well as a tray denesting system and an automatic tray loading system. LEAFSHRINK is a modified atmosphere packaging (MAP) that uses a shrink film and a cardboard carrier. This ensures the Plastic volume reduced by up to 85 per cent and fully recyclable waste is generated.

Also on the stand will be a flow-pack machine for tortilla packaging, a resealable MAP packaging solution with a longitudinal zip. These highly flexible packaging machines are ideal for all users who want excellent format flexibility with optimised packaging costs. Ulma's flow-pack machines offer various options for resealable packaging, such as glue or zips along or across the pack.

Source: Ulma Packaging GmbH

Ulma Packaging at Anuga FoodTec: Hall 8.1, Stand A020-B039