Polish chocolate manufacturer LOTTE Wedel invested heavily in traysealer technology for its best-selling product. In close cooperation with packaging expert SEALPAC and its Polish sales partner Premac, they developed two high-performance packaging systems for their chocolate-coated marshmallow confectionery.

The history of the company LOTTE Wedel begins in 1851 with the arrival of the German Karl Ernst Wedel in Poland. Together with his wife Karoline, he opened a confectionery in Ulica Miodowa (Honey Street) in Warsaw, where he began selling sweet treats and drinking chocolate. The founder's son, Emil Albert Fryderyk Wedel, trained in confectionery and chocolate factories in Western Europe before taking over and expanding his father's business. Under his direction, the First Wedel factory in Warsaw.

His descendant, Jan Wedel, opens a second company in the Praga district of Warsaw on the east bank of the Vistula. The company manages to maintain production during the first years of the Second World War, but the factory buildings are eventually destroyed during the Warsaw Uprising. After the war, Wedel rebuilds the factory in the Praga district.

Wedel has been part of the LOTTE Group since June 2010, a South Korean-Japanese conglomerate. This is the first investment in Europe by the group, which is the largest chewing gum manufacturer in Asia and the third largest in the world. Today, Wedel is a world-renowned confectionery manufacturer with a diverse range of high-quality chocolate, biscuits and confectionery. Despite its impressive history, the company's logo is still based on the Original signature of Karl Ernst Wedel.

The flagship of the product range

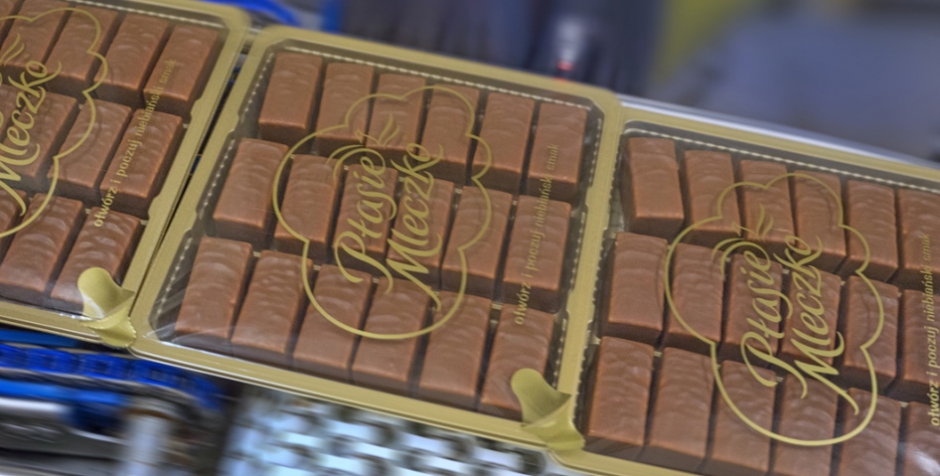

The best-selling product from Wedel is Ptasie Mleczko, a confectionery covered in chocolate and filled with soft milk foam. The name literally means „Bird's milk“, This is a substance produced by some birds to feed their young and is reminiscent of milk. However, ptasie mleczko is also a Polish expression meaning „an unattainable delicacy“. It is one of the most famous chocolate products in Poland.

Jan Wedel developed the first Ptasie Mleczko back in 1936, and today Wedel offers the treat in large quantities and with different fillings, such as chocolate, vanilla, lemon, coconut and, more recently, caramel flavours, but always covered in a delicious layer of chocolate.

The advantages of traysealing

Wedel invested in a new production line for its Ptasie Mleczko. Previously, two open trays were stacked on top of each other with an intermediate layer of paper and then packed in a cardboard box. This not only made the chocolate-coated marshmallow confectionery susceptible to damage, but also resulted in a high consumption of packaging material. A few years ago, discussions began with potential suppliers about alternative packaging solutions.

The company finally came into contact with Sealpac, the manufacturer of high-quality traysealer and thermoformer systems, through its Polish sales partner Premac in Warsaw. The suggestion was Use of traysealer technology, to optimise the production process of Wedel's Ptasie Mleczko. With this new packaging system, the cost-intensive paper liner would no longer be necessary. In addition, the chocolate-coated marshmallow confectionery would be much better protected by the top film sealed to the tray. In addition, the shelf life could be extended compared to the previous solution and the fully automated traysealing would significantly increase overall production output.

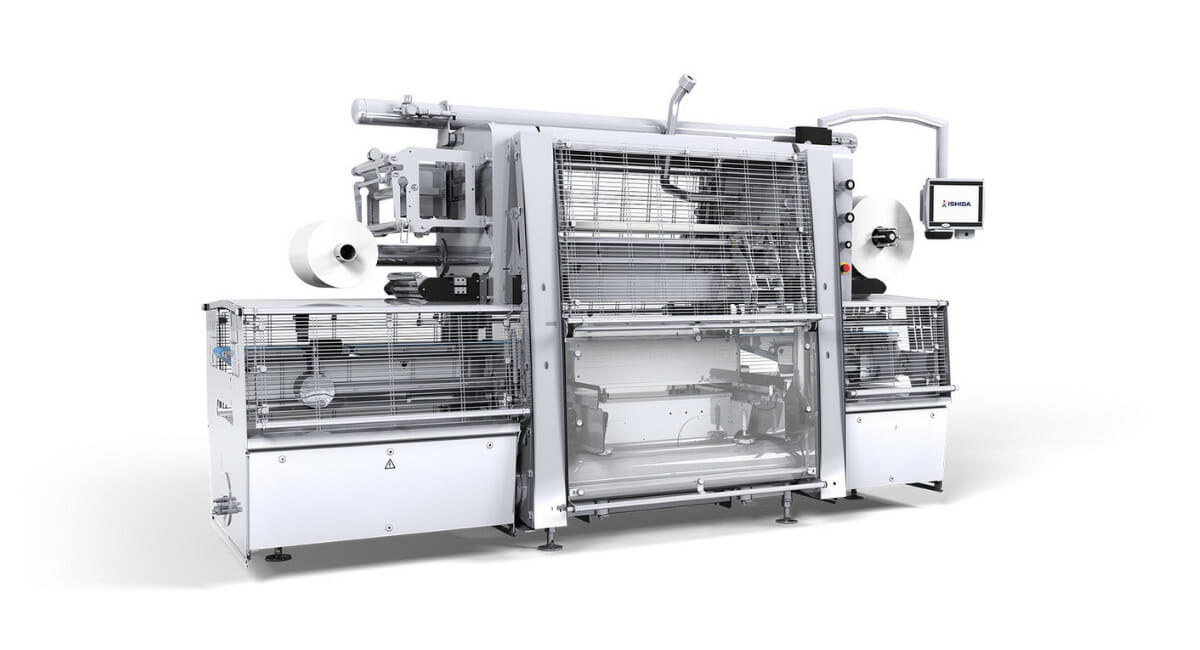

In 2013, Wedel decided in favour of the purchase of two double-lane Sealpac traysealers, an A8 and an A10 system. Premac carried out the smooth assembly of the two traysealers at LOTTE Wedel and was responsible for instructing the operators and technicians.

Optimum synchronisation

In the first few months, Premac and Wedel put a lot of effort into increasing the output of the production lines by continuously optimising the various steps in the production process. Once the chocolate-coated marshmallow confectionery has been produced according to Wedel's secret recipe, the product enters the loading zone, where it is picked up by robotic arms and six pieces at a time are packed into the automatically unstacked tray. The trays are then transported to the buffer zone, where they are stored until they are transferred to the A8 traysealer.

The Line distributors from Sealpac ensures that the trays arriving in a single lane are fed smoothly into the double-lane tray infeed. The sealed trays, ten of which are sealed at a time, return to the single-lane infeed and are then packed into their outer packaging by a robot. With the double-lane traysealer system Sealpac A10, both the infeed and outfeed are double-lane. In this case, at least 14 trays are sealed in each cycle.

Smooth-running servo technology

Both traysealers were installed on the first floor of the historic Wedel building. For this reason, the impact of the systems on the floor had to be calculated beforehand in order to determine whether additional reinforcement of the floor would be necessary. However, due to the servo technology used in the A8 and A10, the vibration effect on the floor was limited. The use of servo-driven lifting and gripping systems also enables careful handling of the tray and its contents. In addition, servo technology reduces air consumption and maintenance costs.

High performance, low downtime

Both traysealers currently run at more than twelve cycles per minute, achieving a production output of up to 175 trays per minute. This was a challenging task for such a sensitive and light product. For example, Sealpac used special heat-resistant protective plates in the sealing station to prevent the chocolate from melting.

For continuous operation of the system, it is important to Production line downtimes as low as possible. A special Crash detection function inside the traysealer automatically recognises when one of the chocolate items protrudes beyond the tray just before sealing. If this is the case, the system tools do not close, preventing potential breakage and the resulting time required for cleaning. Given the high production speeds involved, the top film has to be replaced relatively frequently. For this reason, both the A8 and A10 traysealers are equipped with a tandem film arm, so that it is possible to quickly switch to the other film roll when one roll comes to an end. In addition, Premac's technicians are available just round the corner to provide professional assistance at any time, should this be necessary.

Attractive packaging

Ptasie Mleczko are mainly packaged in trays of 18 pieces (380 g). Each tray is securely sealed with a printed film that can be easily removed by the consumer for the entire shelf life of the product. For maximum convenience, the tray is provided with a large, clearly marked peel-off tab. During the sealing process, Wedel uses the Inside cut technique from Sealpac, in which the film is first cut and then completely sealed inside the tray. This enables a more attractive presentation than with the conventional outside cut and minimises film consumption. This technique also ensures that the trays fit snugly into the outer packaging.

Thanks to the extended shelf life Wedel is now in a position to offer its products around the globe. The company already sells its products in over 25 countries worldwide, with the USA, Canada and the UK currently being the key markets. Thanks to an intensive marketing campaign (Wedel is represented at trade fairs in Moscow, Paris and Ireland, for example), the sales area is expected to expand even further in the coming years.