Multi-stage vacuum generators from SMC's ZL series are suitable for pick-and-place applications in various industries. With the IO-Link extension, processes run more reliably and efficiently. The ZL3/ZL6 models combine high suction power and low weight.

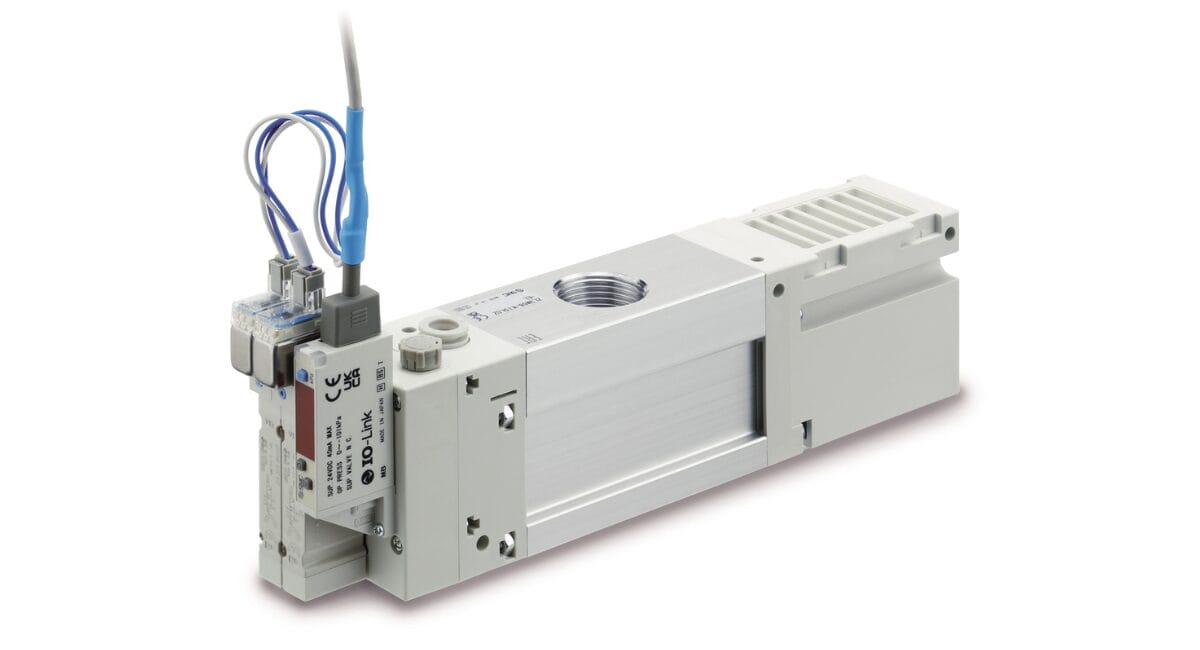

In many places, modern pick-and-place applications require small, lightweight and powerful vacuum generators that perform reliably with both large workpieces and moving robot parts. To Processes, security and connectivity to further improve the quality of its products, automation specialist SMC has now equipped the two multi-stage vacuum generators ZL3/ZL6 of its ZL series with an IO-Link interface.

Both models also score points with a maximum suction volume flow of 300 l/min (ZL3) and 600 l/min (ZL6) and are completed by the ZL1 model (100 l/min, ANR in each case). The IO-Link communication increases the degree of automation and process reliability In addition to remote monitoring and data utilisation in real time, malfunctions can also be detected more quickly. All in all, the ZL series is an economical all-round solution that also helps to reduce application errors and IT costs thanks to the IO-Link extension.

As before, the high suction power shortens cycle times and therefore increases output, while the low weight enables lightweight machine designs. In short, the ZL series provides flexible all-round vacuum generators for Industry 4.0 - which simultaneously save space, weight and costs while increasing efficiency, safety and connectivity.

Control with sensor monitoring

In use, the IO-Link extension of the ZL series enables better control of device status and production processes. Thanks to sensor monitoring, malfunctions can be detected more quickly, which is a plus for process reliability. If required, vacuum generation can also be controlled remotely via optional pilot valves that can be mounted on the housing. This allows the Compressed air supply switched off on the control side which reduces energy costs. The already reduced weight compared to previous models (e.g. by 44 per cent for ZL3/390 g compared to the previous ZL212/700 g) ensures a lower moment of inertia when using the vacuum generator in moving applications (e.g. robot arm). In addition, this enables the design of particularly small and cost-effective machines.

Air consumption and therefore energy costs can be kept in check with the help of special features: For example, all models in the ZL series have a Nozzle design with 3-stage diffuser, which can more than double the suction volume flow with the same compressed air supply (single version for ZL1, ZL3; double version for ZL6).

The ZL3/ZL6 models can also be equipped with an optional digital vacuum switch including an energy-saving function. The resulting self-regulating control circuit reduces air consumption by up to 91 per cent: Vacuum is only generated on demand and the compressed air supply is automatically switched off when the desired vacuum level is reached. This is not only easy on the wallet, but also on the climate.

Installation of the ZL series is still quick and easy: The double threaded connection (vacuum connection 1/2″) allows the ZL3/ZL6 models to be connected directly without additional T-fittings - saving time and money. An optional adapter is available for mounting from below, for example for machine updates without changing the mounting hole (ZL1/ZL3). In addition, a setting needle for Damping of the blow-off pulse for gentle loosening of sensitive components or workpieces. The increased process reliability reduces the time and cost of potential production errors.

Thanks to IO-Link, the even more versatile all-round vacuum generators from the ZL series make pick-and-place applications in numerous industries safer and more efficient - from the Food industry, automotive and life science. Small, light and powerful, they are ideal for assembly in moving robot applications and for suctioning glass panes (e.g. ZL1), clamping workpieces (e.g. ZL3) or transporting cardboard boxes (e.g. ZL6).

Source: SMC