The dimensions of the chocolate bars in 100 gram format are just as varied as the different Ritter Sport varieties. A difference of just three millimetres in thickness poses a challenge when it comes to packaging ready for sale. The new solution from Schubert now handles this process fully automatically and directly on site within the production chain.

One reason for Ritter Sport's continuing success story is that sustainability has always been a top priority for the company. The fact that there is always room for improvement is demonstrated by current projects from Waldenbuch, in which Ritter Sport is extensively testing a new type of special paper packaging as part of a major campaign with 500 loyal chocolate fans and testing its suitability for everyday use.

Three millimetre challenge at Ritter Sport

From a sustainability perspective, the packaging process for the 100 gram bars was also recently put to the test. Due to the different dimensions of the individual varieties, sorting and packaging ready for sale previously had to be carried out in an outsourced Logistics process by hand take place. The system used could not automatically cope with differences of up to three millimetres in thickness for product types such as nougat and whole nut.

"We wanted to optimise this complex process in a cost-efficient and sustainable way. That's why we were looking for an in-house solution, which packs our 100-gram bars directly in the right formation and reliably recognises whether ten, eleven, twelve or thirteen bars need to be sorted into the box", explains Ivo Bǔncǔga, Head of Technology at Ritter Sport. A question with which he specifically approached the packaging machine manufacturer Schubert. Ritter Sport has a long-standing, trusting partnership with Schubert. Jonas Müller, project manager at Schubert, took on the challenging task. Within a very short time, he developed a compact, flexible and effective machine solution for the company.

Intelligent technology for customised packaging sizes

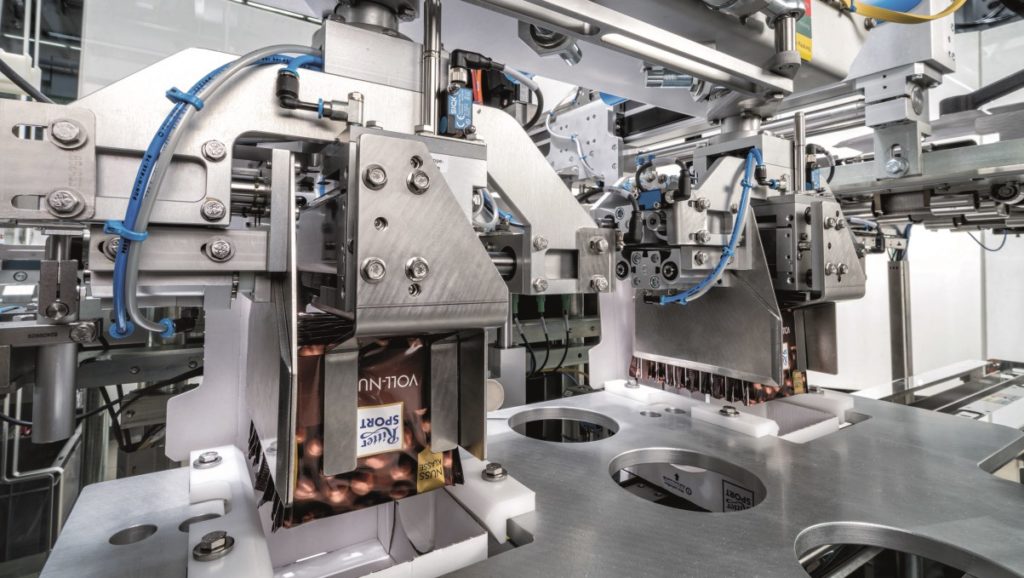

The compact machine consists of a transfer unit, three F2 robots for erecting, filling and closing the cartons and a downstream turning unit in a single frame.

It is also designed to be so flexible that it can be optionally connected to the existing packing machine for packing in alternative cardboard packaging via an additional height-adjustable swivelling conveyor, depending on the production order. As a rule, the 100-gram sheets on the Schubert system are packed at a speed of 400 sheets per minute directly from a flow-wrapping machine in a single lane.

Sorting then takes place via a grouping chain according to the sheet thickness in the exact quantity for the carton instead.

TLM system turns everything upside down

Before the chocolate is filled into the cartons, they must first be made from one-piece blanks, which are stored flat in a magazine, erected become. "The fact that the cartons no longer consist of a base and lid as before means that we can simplify and speed up the packaging process many times over," says Marco Wleklinski, the project engineer responsible at Ritter Sport. The flat blanks are removed from the magazine, glued and pressed through a folding frame by an F2 robot. The erected modular carton is placed "upside down" on a vacuum conveyor, which guides the cartons through the system to the collating table.

There, an F2 filling robot inserts the products, also upside down, into the carton lid. Another F2 robot then closes the attached base section.

He places the box in the Reversing unitwhich rotates the cartons by 180 degrees: it then places them on the outfeed conveyor.

Excellent and sustainable

With the help of the new system, the following No time-consuming format changes necessaryonly the grouping tables vary due to the different bar thicknesses and can be changed quickly and easily with just one tool. Asmus Wolff, Managing Director and Supply Chain Manager at Ritter Sport, is visibly impressed: "This really is an ingenious 'toy' that Mr Müller and his team have built for us."

Thanks to the new system, Ritter Sport is actually saving 30 per cent of storage space and cardboard packaging potential that can now be utilised to implement further ambitious sustainability standards. The family business has already received several awards for its extraordinary commitment in this area. This is also a matter close to the heart of the head of the family and retired Managing Director Alfred Theodor Ritter, who radically modernised the company in 2004 and has been intensively committed to environmental issues and employees for decades. For this, the 66-year-old received the German Founder Award 2019 in the Lifetime Achievement category.

[infotext icon]Ritter SportThe chocolate treat from Baden-Württemberg, which has been popular for more than 100 years, was not square from the start. Nor was it called Ritter Sport. The chocolate in 100 gram format owes its unmistakable trademark to a pioneering idea by Clara Ritter in the 1930s. She developed a square chocolate with the same weight as a long chocolate. This fitted perfectly into the pocket of the sports jackets commonly worn by football fans at the time without breaking. The Ritter Sport brand was born. It continues to conquer the world today with more than 22 delicious flavours. With the slogan introduced in the 1970s „Square. Practical. Good.“, the square chocolate from Germany secured itself a place in the eternal list of the best brands and continues to enjoy unbroken international popularity to this day.