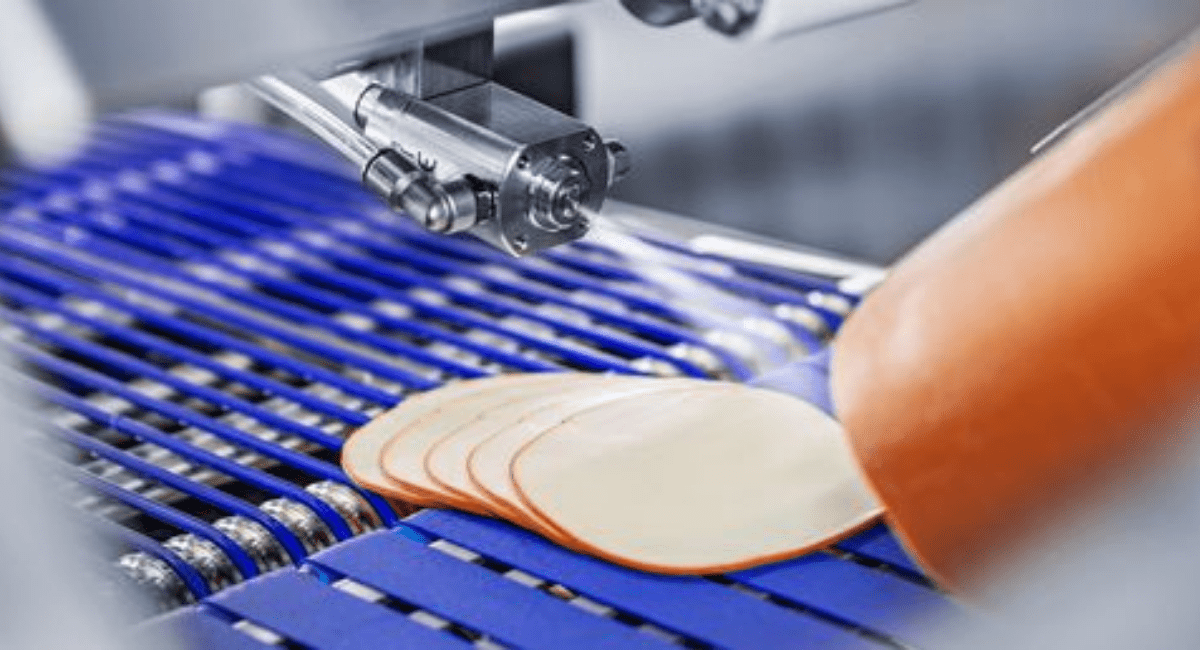

With the SprayTech technology developed by Weber Maschinenbau, an imperceptible release agent can be sprayed onto slices of sausage or cheese. This makes it easier to remove from the packaging.

With the help of the intelligent Weber SprayTech technology, a release agent that is imperceptible to the consumer is sprayed onto the product so that individual slices of a portion can be removed more easily and without damage. The technology is used for products that strongly adhere to each other due to their nature, such as cheese or vegan products. The Weber SprayTech is also ideal for applications with often very thin slices, such as cooked ham.

SprayTech as an alternative to the interleaver

In addition to the naturally occurring adhesion, the thinly sliced discs of such products are particularly sensitive. In many cases, the Weber SprayTech can therefore fulfil the function of a Replace conventional paper or film interlayer and is therefore an environmentally conscious, sustainable alternative to the interleaver. The use of SprayTech technology is particularly exciting for products that simply do not allow the use of paper or film to separate the individual slices. The Weber SprayTech therefore opens up Completely new fields of application.

One example: the use for shaved applications. These wafer-thin slices adhere strongly to each other after a short time and are difficult for the consumer to remove, usually without damaging them. Classic interleaver layer pads have their limits here. Weber SprayTech provides a remedy and makes it possible for even Simply separate slices of shaved meat from each other leave.

Bioprotection extends shelf life

In order to use resources sustainably and avoid unnecessary soiling in the slicer room, the Weber SprayTech only when the knife releases the product - an additional plus in terms of sustainability. Track-related vario applications can also be realised. In addition, the application of luxury products or shelf-life extending agents is conceivable and can be realised with the SprayTech.

The latter in particular, so-called Bioprotection, is a promising technology for the future and is of interest to both food processing companies and retailers. In addition to extending the shelf life of foodstuffs, certain agents also offer the property, delay the growth of pathogenic germs or even prevent it. This has several positive effects: greater sustainability through less food waste and greater food safety.

The SprayTech can be fully integrated into all current Weber and Textor slicers and is therefore also suitable for retrofitting existing machines. The technology is conveniently operated directly via the familiar Weber Power Control operating terminal.

[infotext icon]Weber Mechanical Engineering is one of the leading system providers for slicing applications and the automation and packaging of fresh products. The company employs around 1,500 people at 22 locations in 18 nations. The company is still family-owned today and is managed by Tobias Weber, the eldest son of company founder Günther Weber, as CEO.Source: Weber Mechanical Engineering