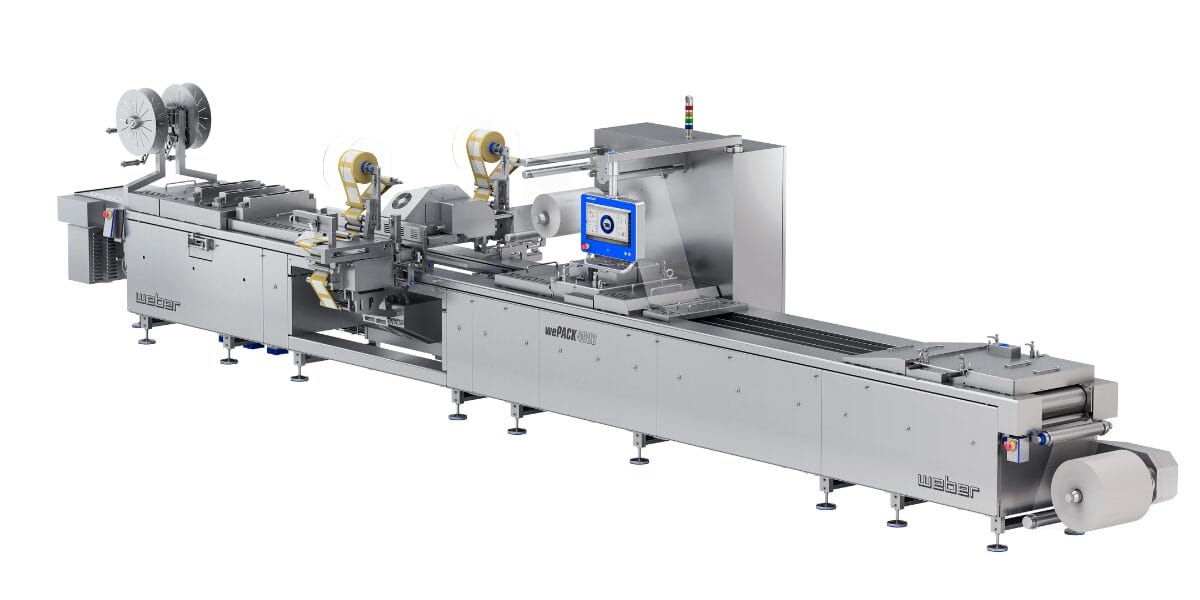

The new, compact Weber wePACK 4000 thermoforming packaging machine is perfect for medium output classes and output quantities of up to 100 packs per minute. The wePACK 4000 is the ideal choice for full-range retailers and food producers who tend to produce smaller batches. The wePACK 4000 packs sliced meat applications as well as piece goods or fresh meat and poultry products safely and efficiently.

The wePACK 4000 also uses servo technology for the chain drive. The new thermoformer also impresses with Very good accessibility for simple service and maintenance work. A highlight in this respect is the quick-change system for forming and sealing tools. The upper mould of the wePACK 4000 can be easily folded down with a single movement.

The thermoformer is particularly suitable for MAP, vacuum and standard skin applications. Both rigid and flexible films can be used, making the wePACK 4000 absolutely future-proof. Thanks to the use of a special gas flushing system for MAP applications, the wePACK 4000 is able to, Reduce waste. This is because the residual strips on the bottom film side are reduced by approx. 50 per cent, while the residual strips on the top film side are completely eliminated.

On the Specialist pack in Nuremberg, the wePACK 4000 will be presented for the first time in Combination with the efficient cross web labeller Weber weLABEL. Compared to other labellers Weaver has achieved a unique integration with the packaging machine.

Weber at Fachpack: Hall 1, Stand 434