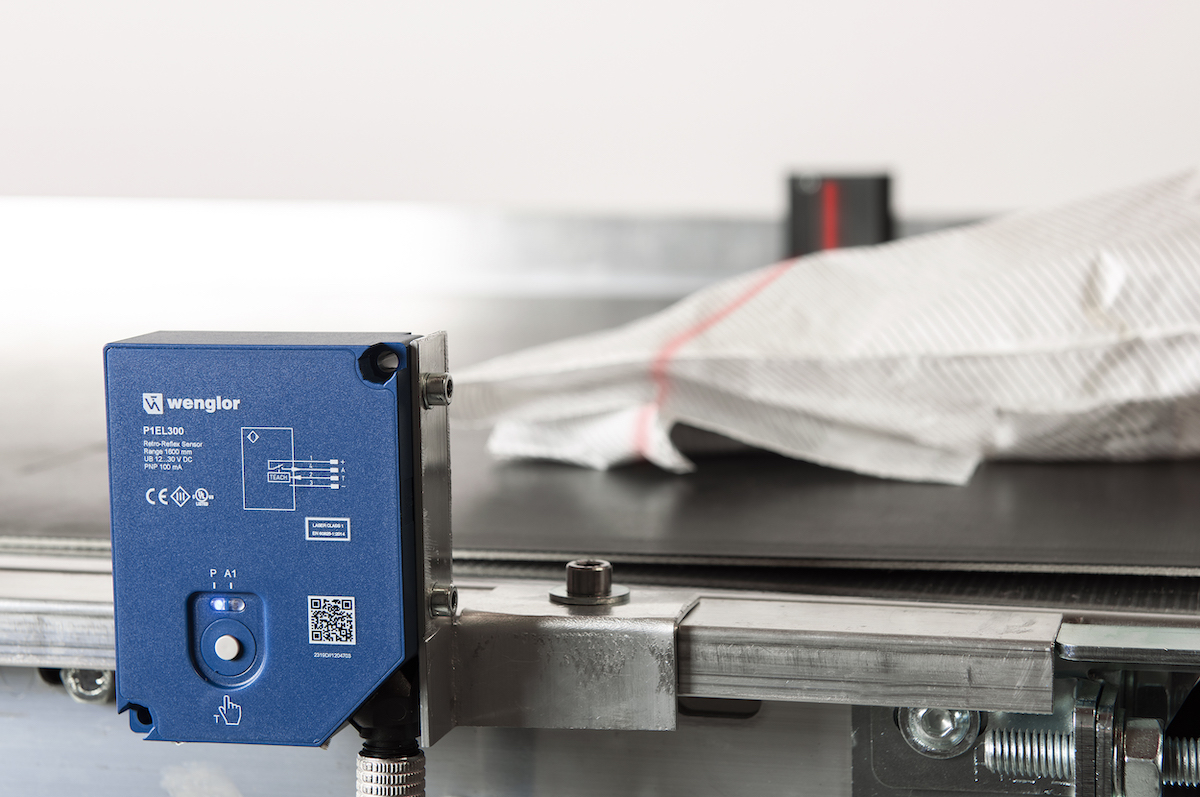

Convincing all along the line: thanks to their continuous and homogeneous light band, the new wenglor reflex barriers can also reliably detect objects with irregular or asymmetrical shapes, for example in intralogistics.

Higher productivity and system availability with reduced costs

With three models With a wide range of light band heights, high user-friendliness and special logistics functions, wenglor offers an economical and easy-to-operate solution to prevent congestion zones and overlapping in storage processes, for example.

The P1EL100 (27 mm light-band height), P1EL200 (42 mm light-band height) and P1EL300 (54 mm light-band height) reflex barriers with light-band were designed as Two-dimensional light barriers with a homogeneous laser light band.

They recognise objects with varying shapes or perforated surfaces - even dark, transparent or shiny objects are detected precisely. And with a range of up to 1.6 m.

„In contrast to comparable products on the market, all wenglor models - thanks to the collimated, homogeneous laser light band laser class 1 - detect the smallest parts from 4 mm in size over the entire range of 0 to 1.6 m.

In addition, smart sensor functions such as the fading out of conveyor belt unevenness with Dynamic Teach, the dynamic readjustment of the switching threshold, as well as the very slim housing with a width of only 27 mm, offer enormous advantages in terms of both application and installation.“

Stefan Reetz, wenglor product manager

Quick and easy commissioning thanks to the teach-in button

This means that the sensors with light strip can be quickly and easily taught-in at the touch of a button. Clever: To prevent unintentional button contact and ensure flush installation, the button has been placed in a slightly recessed position on the housing. Even a External teaching is possible via the control unit using a 24-volt voltage signal.

No less useful for use on conveyor belts is the Dynamic Teach function. This means that unevenness in the conveyor belt can be easily masked out. In the additional precision teach mode, even the smallest parts from 4 mm in size can be reliably detected.

Variable assembly equipment for every system

The sensors combine transmitter and receiver in a slim housing (only 27 mm wide), which can be attached to the side panels of conveyor systems in just a few simple steps.

The sensor connector can be flexible assembly can be rotated by up to 180 degrees, suitable mounting brackets, M4 through-bolts and press-fit sleeves as well as reflector sets facilitate precise mounting and alignment of the reflex barrier.

Source: wenglor sensoric GmbH