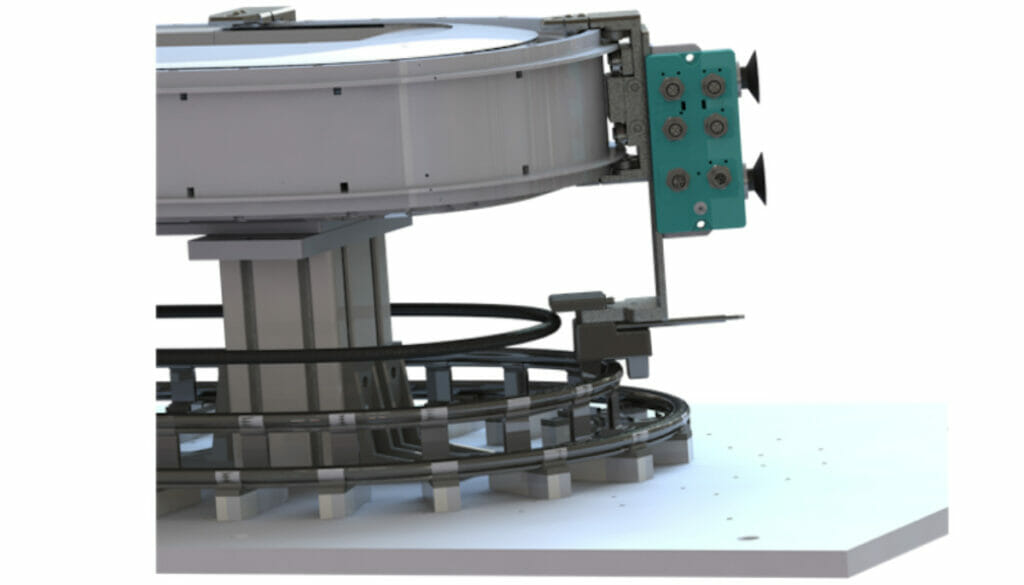

Paul Vahle GmbH has a new service offer for manufacturers of packaging machines. The company has entered into a strategic partnership with CoreTigo and combines its inductive energy transmission with wireless real-time communication systems.

The advantages of the solution from Vahle and CoreTigo can be seen in the stages of machine design, machine production, machine construction and with the operators of the systems. For example, a Increase in production capacities through simultaneous assembly processes reached during the journey of the goods carrier.

"We want to improve our service offering not only by further developing our own products, but also by providing our customers with a comprehensive overall package through targeted strategic partnerships. The wireless real-time communication systems from CoreTigo are an ideal addition to our inductive energy supply solutions and significantly expand Vahle's portfolio of system solutions."

Achim DriesCEO of the Vahle Group

Furthermore, a wide range of packaging variants can be utilised on a single machine. This means that the Reduce changeover times between different packaging types or are completely eliminated. At the same time, the use of these technologies reduces the space required for machines and systems, as fewer cables and external robots are required. The permanent machine and process analysis, based on the available real-time data, enables preventive maintenance to avoid downtimes and increases the availability of the machines.

Through this cooperation, the company is addressing the factory automation sector. "Especially for the manufacturers of packaging machines that require High-availability communication solution with low latency times and deterministic behaviour for real-time control and monitoring We can offer considerable added value with IO-Link Wireless," says the CEO. In the long term, this system solution will also be extended to other markets. "The strategic partnership with CoreTigo will enable us to respond even faster to the dynamic requirements in various automation areas. Customers in various sectors will benefit from this," emphasises Dries.

Source: Vahle Group

More news on the topic of automation

Modular platform for autonomous mobile robots

Packaging machinery sector sees moderate growth

Automation to combat staff shortages in dispatch

LogiMAT 2026 showcases packaging as an intralogistics driver