Packaging can be an important lever for manufacturing companies to fulfil climate targets. This is because it also has an impact on CO2-footprint of the packaged product. What does this have to do with IQ? A lot! The impact quotient is a measure of the proportion of ecological expenditure for the production of the packaging in relation to the contents.

„The CO2-The carbon footprint is an important measure that quantifies the impact of a company or product on climate change. It allows us to identify the specific areas where the highest emissions are generated. This allows us to develop strategies to reduce them efficiently and promote more sustainable business practices,“ explains Wilhelm Dyckerhoff, member of the Gemeinschaft Papiersackindustrie e. V. (GemPSI). A paper bag for 25 kilograms of food, for example, has a CO2-footprint of just six grams of CO2e/kg filling weight. In comparison, a 1-litre disposable PET bottle for water has a CO2-footprint of 96.5 grams of CO2e/kilogramme filling weight and packaging for sliced cheese 313 grams of CO2e/kg filling weight.

„Whether packaging makes ecological sense can be assessed by looking at the interaction between the packaging and the packaged product,“ says Dyckerhoff. „In the case of packaging for high-quality products, it is not just the CO2-footprint of the packaging, but also the savings that are achieved through product protection.“ The chart shows that the total CO2 increases if too much or too little packaging material is used.

Product group Filling material | CO2-emissions Paper bag [g CO2/bag] | Filling weight [kg/bag] | CO2-Paper bag emissions per filling material [kg CO2/kg product] | CO2-emissions Filling material [kg CO2/kg product] | Impact quotient paper bag [Per cent] |

Foodstuffs | 174 | 25,0 | 0,0070 | 3,5 | 0,160 |

Building materials | 87 | 22,7 | 0,0038 | 2,0 | 0,161 |

Cement | 78 | 25,0 | 0,0031 | 0,6 | 0,335 |

Chemicals | 178 | 25,0 | 0,0071 | 6,0 | 0,058 |

The examples show that the paper bag for these filling goods has only a minimal IQ on the CO2-footprint of the filling material. (Source: GemPSI)

Packaging fulfils various protective functions. First and foremost, it protects the packaged product mechanically during transport and storage, but also from damage caused by moisture or oxygen. Packaging should therefore be tailored to the entire supply chain of the packaged product.

„In order to develop an ecologically sound paper sack, in some cases it even makes sense to use more material in order to minimise CO2 to save money. We follow the motto: as much as necessary, but as little as possible. As an independent processor, we advise our customers on which material and how much of it is appropriate in each case.“

Wilhelm Dyckerhoff, member of the Gemeinschaft Papiersackindustrie e. V. (GemPSI)

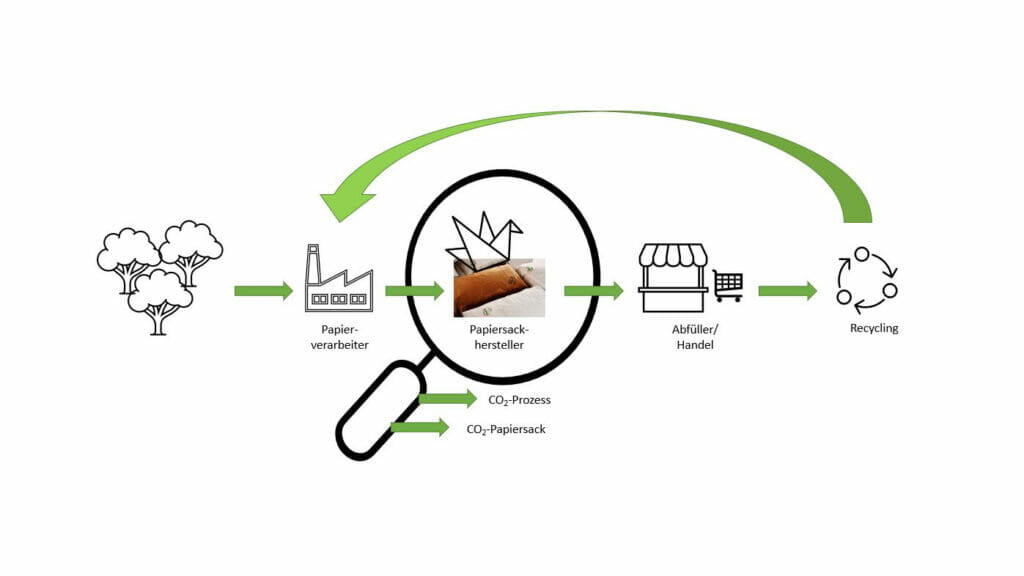

CO2 footprint of a paper bag

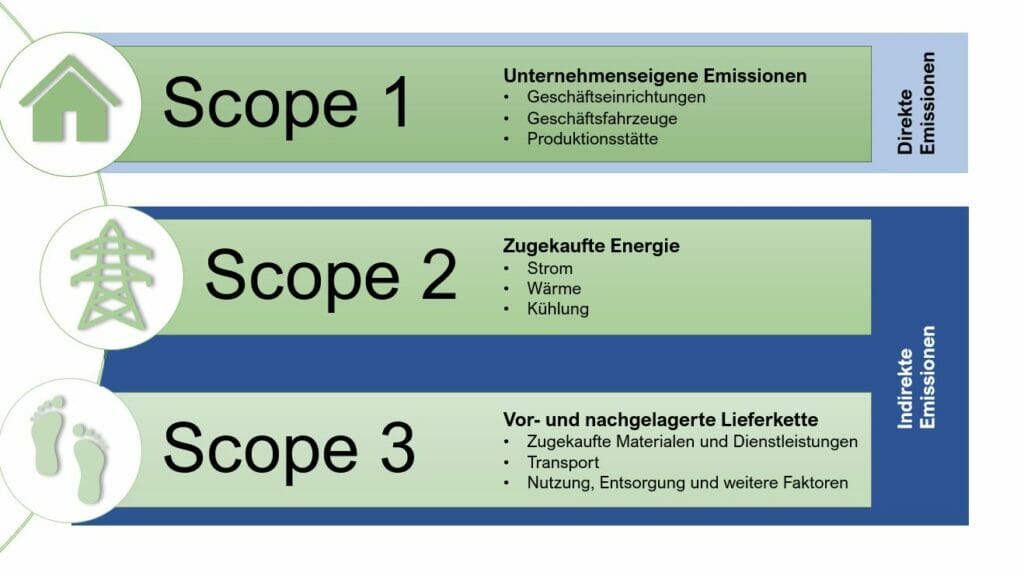

The calculation of the CO2-The carbon footprint of a paper sack includes Scope 1, 2 and 3 emissions. Scope 1 summarises all emissions generated within the company, for example by operating facilities and vehicles. Scope 2 describes indirectly generated emissions through the use of purchased energy. Scope 1 and 2 are the easiest areas for paper sack manufacturers to influence. „There are various initiatives within the GemPSI member companies, for example through the modernisation of plants, the use of electric vehicles and energy-saving energy management,“ explains Dyckerhoff. „However, Scope 1 and 2 only account for two to four per cent of CO2-footprint of a paper sack. Scope 3 accounts for the largest share at around 90 per cent.“ This includes all indirect emissions in the upstream and downstream supply chain, from the purchased raw materials and their production and transport through to the end of a product's life cycle. Processors can obtain the corresponding data for the paper sack with the CO2-footprint calculator from RISE for their customers.

Influencing factor raw material on Scope 3 emissions

Of the raw materials purchased, paper as the main component of the paper sack has a major influence on its Scope 3 emissions. The sack kraft paper used consists of renewable raw materials, which are obtained from sustainably managed forests. In Germany alone, the forest area has increased by more than one million hectares in the last 50 years despite intensive economic utilisation thanks to sustainable forestry.

A large proportion of this CO2-The storage properties of forests are retained when wood is processed into paper. Paper sacks are therefore during their entire life cycle in the storage of CO2 involved.

If, among other things, this storage property were included in the calculation of the CO2-footprint of an average paper bag, according to a 2020 study by RISE it would be minus 35 grams of CO2e per paper bag is already positive for the climate. What's more, GemPSI has already been the Repasack take-back system for recycling kraft paper bags introduced. Other packaging materials can be produced from the valuable long-fibre raw material of paper sacks through recycling. According to a study conducted by Graz University of Technology in 2021 wood fibre-based packaging can be recycled more than 25 times, without significantly reducing their mechanical properties. According to the Fraunhofer Institute Umsicht, recycling one tonne of kraft paper bags in 2021 saved an average of 183 kilograms of greenhouse gases and 3,150 kilograms of primary resources (wood).

„Compared to other packaging, a paper bag has a very low, and in some cases even negative, CO2-footprint. With a careful, intelligent selection of the raw materials used and their suppliers as well as clever design variants, emissions can be reduced even further,“ says Dyckerhoff. „Thanks to the efforts of our raw material suppliers, we will have even more opportunities to reduce our Scope 3 emissions in the future.“ Whether paper or barrier film: by selecting the best materials in each case and through design refinements, there are many ways to reduce CO2-footprint of the paper sack.

Product protection along the supply chain

A good indicator of the minimum CO2-The Impact Quotient defined by the Munich University of Applied Sciences provides the basis for determining the impact on the overall „packaging and packaged goods“ system. The IQ describes the percentage of packaged products that must be protected from damage so that the resulting CO2-savings are greater than the cost of producing the packaging used. „Including the packaged goods in the packaging design makes sense for the development of the ecologically optimised paper sack, but it is also challenging because it requires a lot of knowledge. We can best advise our respective customers if we understand the downstream supply chain of their product,“ explains Dyckerhoff. „Then we can develop an optimised paper sack with the lowest possible CO2-configure the footprint.“

Paper sacks are extremely hard-wearing and tear-resistant. With a low net weight of the packaging, they typically hold 15 to 25 kilograms of filling weight. Their IQ is therefore generally low. A typical food sack, for example, has an IQ of 0.16 per cent. This means that if one in 625 paper bags protects the contents from damage, the entire packaging has less CO2 than would be caused by a loss of product. One chemical bag would only have to protect the contents of around one in every 2,000 bags from damage.

„In general, particularly low IQ values indicate that the protection of the packaged product is particularly important. The CO2-emissions due to possible product loss are quickly higher in this case than the emissions caused by the packaging.“

Prof Dr Dirk Burth, Professor in the Packaging Technology and Sustainability programme at Munich University of Applied Sciences

Paper - More news

Metsä Board optimises folding boxboard for European markets

Waterscoring for precise folding carton gluing

Metsä Board plans Packaging Design Studio in Milan

Zerkom certification for packaging from Packchampion