Yaskawa will be showcasing a number of new developments for networked Industry 4.0 environments at SPS 2019, including a robot cell in which a single controller controls the robot, servo drives, frequency inverters and I/Os via Yaskawa's „Singular Control“ solution.

The prerequisite for controlling the various components via just one module is provided by the MP3300iec RBT compact machine controller. The data from the various networked machines and components is in turn analysed using the „Yaskawa Connected Factory YCF 1.0“ are determined, analysed and visualised.

When networking components, system parts and software, Yaskawa relies on platform- and manufacturer-independent communication via the „Open Platform Communication Unified Architecture“ standard (OPC UA). Corresponding interfaces are now available for the CPUs Micro and Slio as well as for the HMIs smartPanel and Panel PC available.

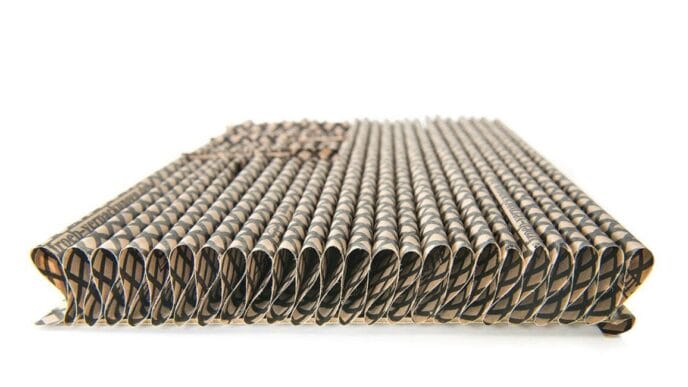

Servo system with EtherCAT interface

Yaskawa shows another example of open interface standards with the Servo controller system „Sigma 7“. In addition to Yaskawa's own Mechatroniclink III bus connection it offers an integrated EtherCAT-interface. The axes are also equipped with integrated Profinet-interface. This allows them to be seamlessly integrated into higher-level system environments without additional power cards.

Also for the proven I/O system Slio Yaskawa is announcing extensions just in time for SPS 2019: New DI/DO modules offer up to 16 digital inputs and outputs. As an additional safety function, the system will also support „Fail Safe over EtherCAT“ (FSoE).

Yaskawa at the SPS 2019: Hall 7, Stand 340