For sensitive goods such as food and beverages, speed and precision, but also cleanliness, are essential in the production line. The hygiene requirements for components in packaging technology are correspondingly high. igus offers a suitable product portfolio in hygienic design: from slewing ring bearings and energy chains to linear and drive technology. Together with the European Hygienic Engineering & Design Group (EHEDG), igus is also working on innovative hygienic design certifications.

During the production and processing of food, it must be ensured that the goods are packaged hygienically. In the food and packaging industry, therefore, all the processes involved must be machines and systems involved fulfil the high hygiene requirements - This also applies to the smallest components.

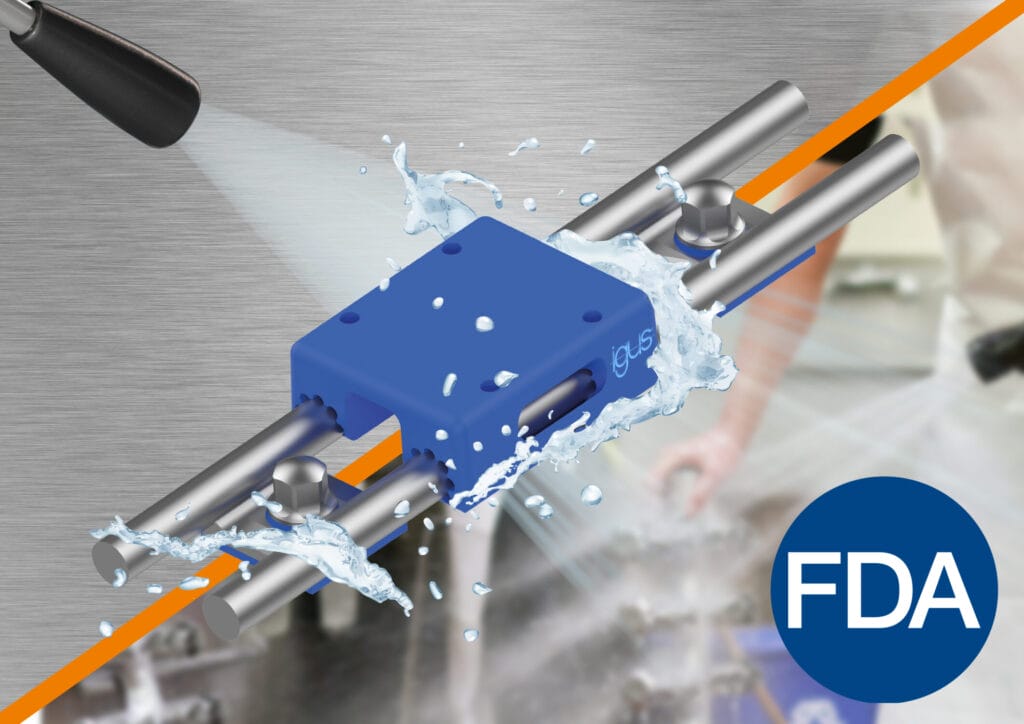

For hygienically perfect movement igus The company offers a wide range of machine components - from plain and spherical plain bearings to linear guides, energy chains and entire automation solutions. The company relies on specially developed and wear-resistant high-performance plastics with FDA and EU 10/2011 approval. The speciality: The so-called „motion plastics“ do not need to be lubricated with oil or grease. Solid lubricants incorporated into the materials enable low-friction dry running and thus improve hygiene, increase reliability and reduce maintenance costs considerably. Even daily cleaning with water, steam and aggressive cleaning agents does not affect them. This is because the plastics are corrosion-free, resistant to chemicals and do not need to be relubricated after a cleaning process.

Food safety with hygienic design

At drylin linear and drive technology, plastics in the form of linear plain bearings are combined with „soft“ stainless steel as a sliding partner when Corrosion resistance and FDA conformity are required. These are usually non-hardenable types of stainless steel that are highly resistant to chemicals. The systems often have the same dimensions as recirculating ball bearing guides and are particularly lightweight thanks to the lubrication-free high-performance polymers, Dust-resistant and easy to clean.

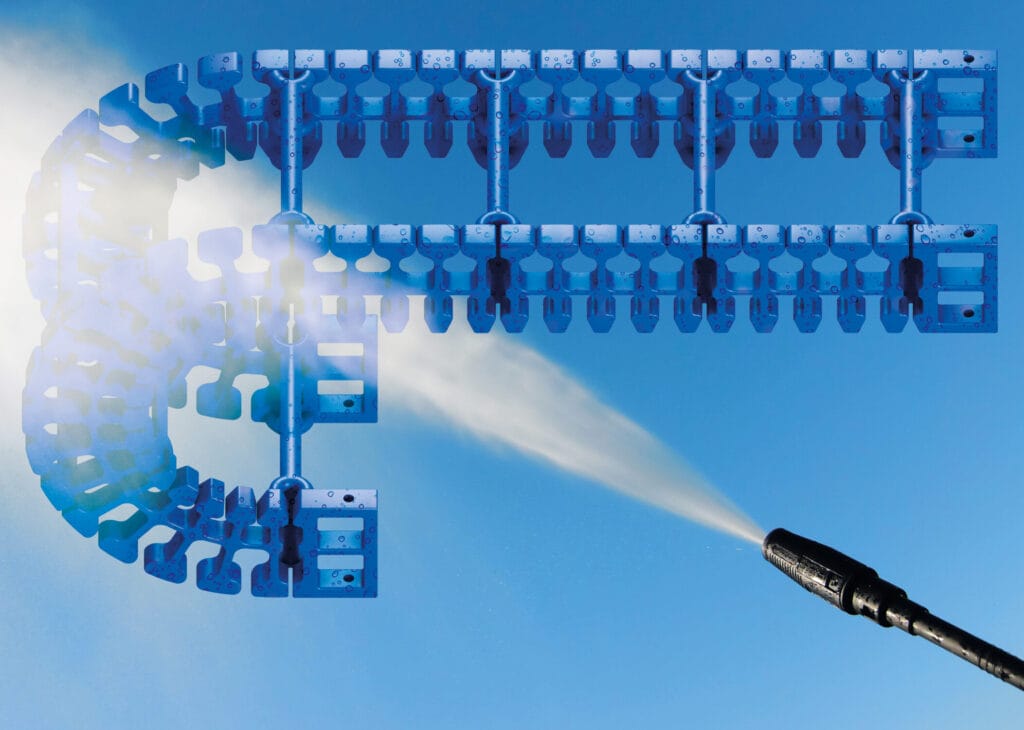

In order to offer users even more safety, igus not only develops solutions that fulfil FDA and EU requirements, but also meet the guidelines of the European Hygienic Engineering & Design Group (EHEDG) with regard to cleanability. These require that components either have a have a gap-free design or are encapsulated accordingly must be. The specifications serve igus as a guideline for hygienic design product innovations. The design freedom, especially in plastic injection moulding, also meets these requirements, for example the required radii and bevels. The innovations include a PRT slewing ring bearing in an encapsulated design with stainless steel and an FDA-compliant iglidur polymer as a sliding pairing, as well as the world's first plastic energy chain TH3 developed in accordance with hygienic design guidelines.

Rinsable polymer linear slide for efficient cleaning

The company has also continuously expanded its linear technology portfolio with new hygienic design solutions. Last year, for example, a new type of slide was presented for the linear guidance systems in the drylin W modular system. What makes it special: This is the first slide that Made from 100 per cent food-grade plastic consists of. „The design is completely open and free of dead space. The system is fully flushable and therefore hygienic,“ says Michael Hornung, Product Manager for drylin linear and drive technology. The Gap-free design is designed to prevent the accumulation of dirt. Surface quality, sealing materials, rinsing holes, bevelled edges and rounded shapes ensure residue-free rinsing. Users can clean the stainless steel rail on site - even using the CIP process - and always make sure that all dirt residues have been removed thanks to the open design. After easy disassembly, the slide is also suitable for automated cleaning in a dishwasher.

Achieving certification together

Based on this principle, igus has developed the linear guide to series production readiness and is now working on certification. Hygienic design certification was a challenge for a long time, as moving parts have narrow gaps due to their function and existing designs therefore did not fulfil the requirements. „We discuss the issue of ‚open versus encapsulated design‘ with many customers - and the arguments in favour of open systems are convincing from our point of view,“ explains Michael Hornung.

„Our hygienic design developments should trigger a discussion with our customers, but also with bodies such as the EHEDG, and thus generate new ideas. We have therefore also joined the EHEDG with the aim of jointly enabling certification for open moving parts.“

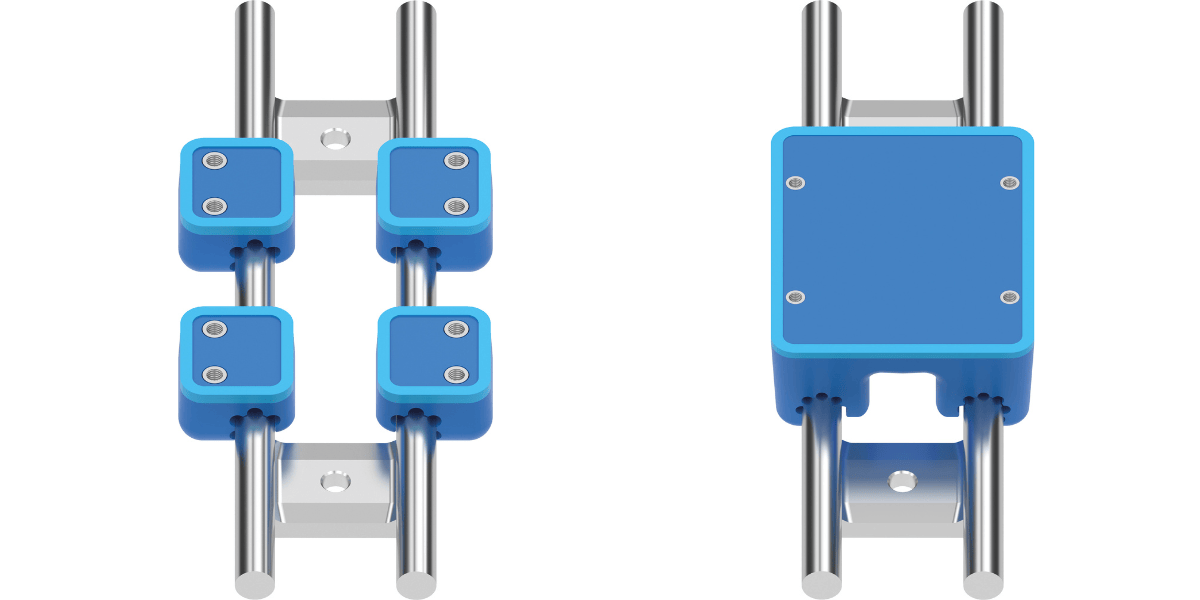

Flexible designs with individual bearings

Following the positive experience with the polymer slide, igus expanded the Hygienic Design modular system this year. It quickly became clear that, in addition to the slide, other solutions were needed that could be used flexibly in the food and packaging industry. The modular system therefore now also includes Single bearing for flexible constructions. Unlike the linear slide, the individual bearings are placed separately on the guide rail and assembled into linear slides using stainless steel plates in various sizes. As with the all-plastic slide, the open and gap-free design enables quick and efficient cleaning. The materials used are also FDA and EU-compliant - and even PTFE-free.

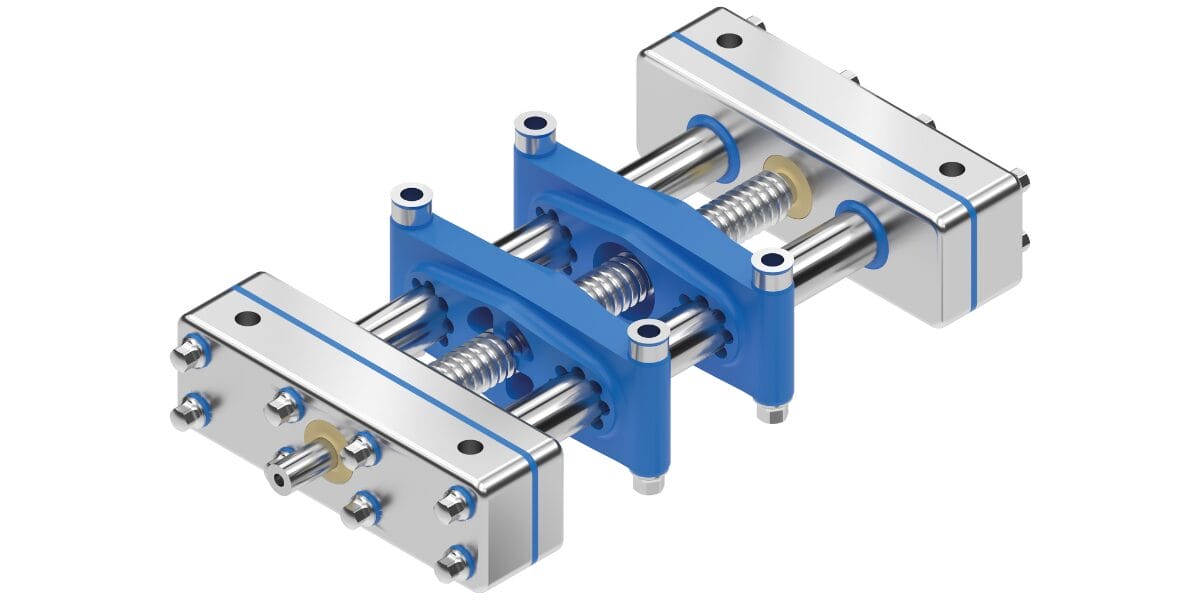

Design study for SHT linear actuator further developed

In addition to the drylin-W modular system extension, igus has also further developed its design study for the ready-to-install SHT linear axis and optimised it with regard to a optimised for better flushability. The system uses stainless steel round shafts as guides and stainless steel dryspin thread technology as the drive, which is characterised by its smooth running and efficiency. All components - whether stainless steel or plastic - were customised according to the same hygienic design specifications. The crosshead assembly consists of two housing halves, which are sealed using an FDA-compliant silicone flat seal and hygienic screws. The shafts are sealed using specially configured wiper seals that prevent dirt and moisture from entering the crosshead. The threaded nut, which runs on the spindle, is provided with sufficiently large gaps so that no dirt can accumulate and efficient cleaning is possible. The specifications for the cleaning process include At least two travel positions for the cleaning process.

„We are working on developing more and more of our products consistently in accordance with the hygienic design guidelines. Complex drive units such as the SHT linear module have never yet been certified. However, we are confident that we will develop new, innovative solutions and certifications together with the EHEDG and our customers.“

Michael Hornung

Tried and tested in practice

The hygienic linear technology from igus has already proven itself in a variety of applications in the food, beverage and packaging industry - for example in the inspection technology of Krones AG. The first step that takes place in the inspection technology of empty returnable bottles is sorting. These checks are the task of the Linatronic 735, which includes a rejection system for sorting out bottles with format adjustment of the linear motor by means of a drylin WS-1040 profile rail made of stainless steel. This and other drylin linear axes help Krones to keep its lines maintenance-free.

drylin timing belt axes are also used in the robotic kitchen of the start-up Cook-e. The electromechanical cooking artist consists of software-controlled modules for storage, dosing and cooking and conjures up fresh dishes without human assistance - and all this in just 2.7 square metres. The toothed belt axes from igus enable all movements in a small installation space - quickly, precisely and reliably - and are therefore also suitable for easy adjustment and positioning tasks in confined spaces where every millimetre counts.