Every day, 450,000 glass bottles are filled at Nürburg Quelle Hermann Kreuter GmbH in the Vulkaneifel region of Rhineland-Palatinate. The company now relies on artificial intelligence (AI) from Indspect for bottle recognition: to achieve a recognition accuracy of well over 99 per cent, the experts created a large number of images in advance and evaluated them manually one by one. The AI then takes over ...

Nürburg Quelle uses white 0.7-litre pearl bottles and green 0.75-litre GdB bottles. However, the crates in the return flow often contain new 0.75-litre bottles (N2) as well as individual bottles from competitors. They are indistinguishable from above and with normal cameras. It took a great deal of effort and a new AI software that works on a high-performance graphics card, for the possibility of detection with Indspect inspection technology.

Development milestones

Hermann Kreuter senior founded Nürburg Quelle as a limited partnership in 1932. The early years for the company were difficult because the company owner did not want to share the political views of the National Socialist rulers. But from 1950 onwards, things began to improve rapidly. Nürburg Quelle grew continuously from ten employees and one million bottle fillings in 1950 to currently 115 employees and an annual output of around one million hectolitres.

Mineralbrunnen set a milestone on 28 November 1968, when it became the first fountain company in Germany to introduce the practical and used a hygienic screw cap thus demonstrating its innovative strength and customer-orientation. Seven years later, on 11 July 1975, the company once again made history: the „Vulkania“ mineral water spring was officially recognised as medicinal water.

The Indspect AI has to differentiate between these bottles, for example (on the right, those of Nürburg Quelle, next to it those of other competitors).(Image: broesele | Montage: packaging journal)

Bottled in pearl bottles

Every year, well over 100 million bottles filled, 65 per cent of which are made of glass. Three PET lines (one-way and two-way PET) and a glass line with a capacity of 30,000 bottles per hour are in operation at the plant in Dreis-Brück. Brown and green 12-bottle GdB crates are used for the glass bottles.

„We have been using camera systems from Indspect for years to recognise the ‚good‘ bottles. However, for some time now, we have increasingly been registering the new GdB bottle N2 as well as individual bottles from other wells in our crates. The previous camera systems were no longer able to differentiate between these foreign bottles, so we ended up having to sort out many foreign bottles manually.“

Hermann Kreuter, is the third-generation managing director of Nürburg Quelle and asked his long-standing partner Indspect for a solution.

Innovative detection technology

For over 20 years, Indspect from Neuwied has been designing a wide variety of Process for checking bottles and crates in the beverage industryCameras, high-frequency technology, laser light section systems, ultrasonic sensors and light barriers detect the colours, shape and size of containers, the presence, correct fit and intact retaining rings on closures, labels and their dating, as well as fill levels. Added to this are the Detection of foreign substances and residual liquids in the bottles, completeness in the full crates, broken handles, incorrect crate colours and logos, foreign objects or incorrect bottles in the empties.

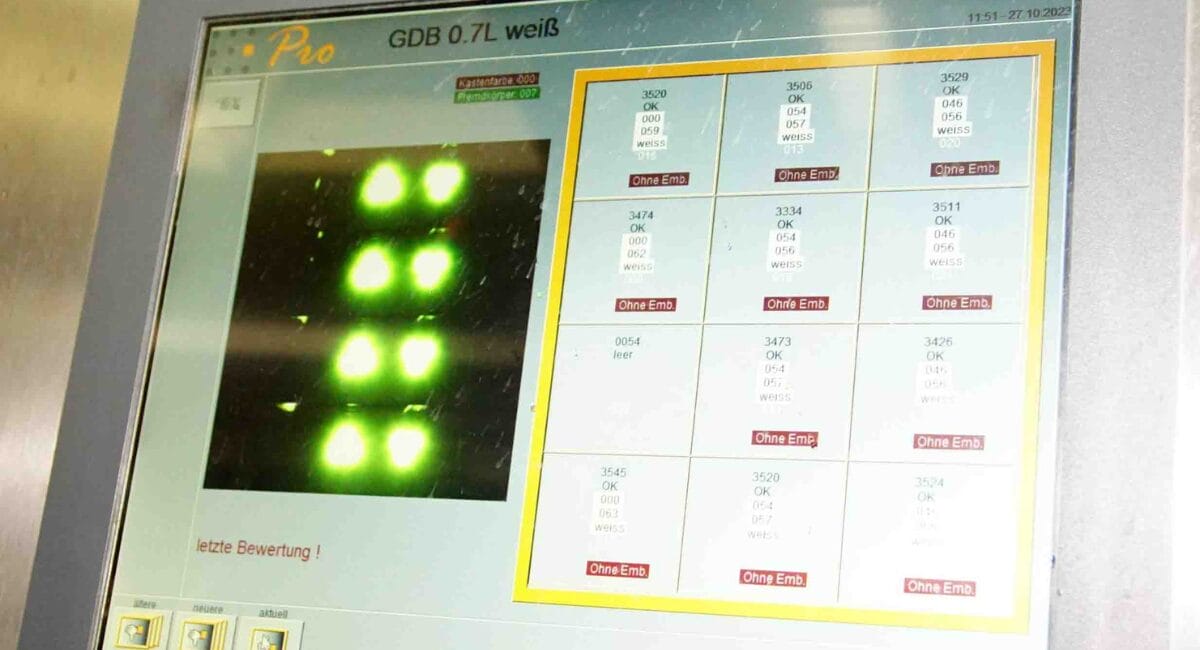

The following are used CCD high-performance cameras in measuring bridges, The crates with the bottles pass underneath in free flow. Just as important is the associated software, which clearly converts the sometimes extremely fast signals in such a way that the bottles and crates are guided into the correct lanes by rejection systems and the complete results are clearly and comprehensibly displayed on a large screen, and errors and good bottles and crates are saved in clear statistics. The Pro, Basic or Eco control units (depending on performance requirements) are used for this purpose.

Problematic differentiation - time-consuming preparation

At the Nürburg Quelle, Indspect uses a Special AI software one. „The desired pearl glass bottle, the new N2 bottle from GdB and the individual bottles from our competitors are almost the same height. What's more, it's almost impossible for our cameras to recognise the differences from above with a shoulder view,“ says Indspect Managing Director Frank Nicklisch, describing the problem. However, AI in no way means that this system learns completely independently, as many people think, „but we have to give the Software as many variations as possible The AI must be able to draw the right conclusions and ultimately distinguish between the bottles,“ emphasises Nicklisch. Firstly, the human has to evaluate each individual image and provide the AI with the result.

(Image: broesele)

At its headquarters in Neuwied, Indspect therefore began to take countless photos of the various bottles from above. Each individual image was then analysed manually and the often minimal difference marked. The Indspect engineers then installed their four CCD cameras and the electronics on the Nürburg Quelle line and took more photos. „In total there were between 25,000 and 30,000 images, which we shot and analysed individually,“ reports Nicklisch. Only then were they satisfied and achieved a Detection accuracy of well over 99 per cent with an output of 30,000 bottles or 2,500 crates per hour.

„The AI gradually draws its own conclusions from this wealth of information and distinguishing features as it trains the model and thus becomes better and better.“

Convincing result

Crates that do not contain any missing bottles go directly to the unpacker and washing machine. Crates with non-production bottles are sent to a separate conveyor for palletising and are later returned to production. Crates with more than one foreign bottle reach the sorting area via a third conveyor:

„We are very satisfied with the new system from Indspect and have far fewer foreign bottles in the process. Of course, the solution would be perfect if 100 per cent of the wrong bottles could be sorted out.“

Hermann Kreuter