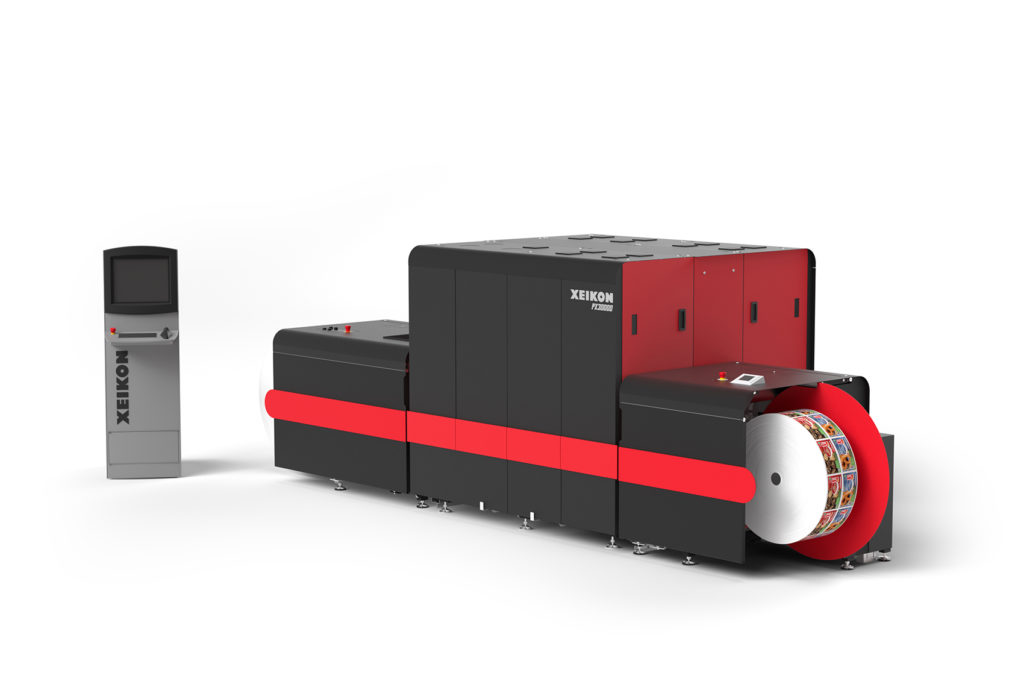

A high-end PX30000 label printing machine has been added to Xeikon's Panther portfolio. It is equipped with eight printing stations, two of which are used to apply the layers for a highly opaque white at maximum printing speed. The label printing system is based on UV inkjet technology and is controlled by Xeikon's industry-leading X-800 digital front end. Its unrivalled feature set is designed to fully exploit the performance potential of digital print production.

The Xeikon PX30000 is an economical solution

Small to medium flexographic print runs can be realised with short delivery times. It enables label printers to produce the widest range of digitally printed labels with a glossy feel, optimum durability and high abrasion and scratch resistance. The press was developed especially for label printers operating in the high-end market for health and beauty products, chemicals and premium beers. Label printers looking for shorter lead times, lower production costs and reduced complexity can now realise new business opportunities with digital printing. The PX30000 is available for demonstration at Xeikon's Global Innovation Centre and is available in Europe and North America.

The Xeikon PX30000 digital press is an extremely versatile solution with an impressive range of performance and functionality. As with all Xeikon digital printing technology, overall equipment effectiveness can be optimised with the optional Xeikon Premium Services. The UV inkjet press Xeikon PX30000 is based on a proven platform driven by the company's X-800 digital front end, which can be easily integrated into existing workflow environments.

For greater flexibility and application diversity, the machine can print in the extended colour space. Here the user can choose between configurations with six or seven colours with seamless control of colour management. The maximum print speed of 70 m/min with opaque white shows that the machine has been developed to maximise efficiency and industry-leading productivity. This web press with full web press technology handles media widths up to 340 mm.

„The industry recognises us as a trusted partner and solution provider. Over the years, Xeikon has created a comprehensive package of really needed services. We support our customers in developing and selling new applications. We help them to seamlessly integrate digital printing into their existing production environment and provide advice and support for the automation of their entire label production. In addition, the workflow of the X-800 front end enables further automation of all processes. Its intelligent imposition algorithms for positioning the labels on the print web can help to reduce costs through shorter production times. This powerful workflow can handle even the most challenging jobs. Even the most demanding jobs with variable data or labels with track-and-trace functions can be handled by the X-800 workflow with unrivalled quality.“ Filip Weymans, VP Marketing at Xeikon

Source: Xeikon