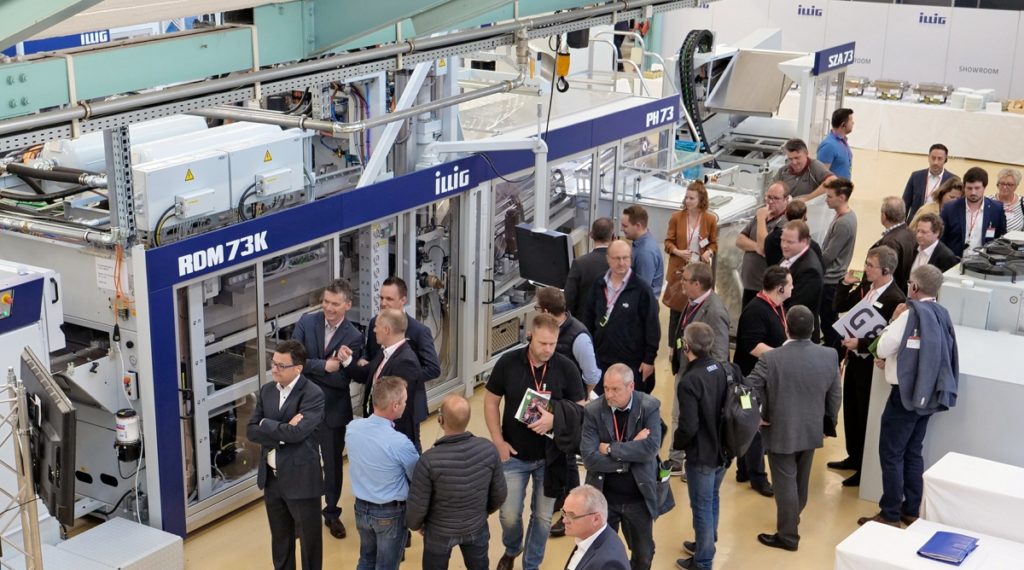

Over 300 participants attended the two-day in-house exhibition of the machine and tool manufacturing company ILLIG in Heilbronn on 8 and 9 May. The 18th in-house event thus set a new record and reflects the great interest in the technology leader's thermoforming expertise.

ILLIG presented with the guiding principle „Circular Thinking!“ sophisticated, sustainable technical solutions in thermoforming for the packaging industry. At numerous stations, the company presented the latest high-performance thermoformers, developments in toolmaking and current service topics. With machine and mould demonstrations under production conditions, ILLIG offered a technological showcase at the highest level.

The new packaging solutions resulting from the consistent continuation of the 360° packaging development Pactivity® The innovative solutions developed for current „circular thinking“ market requirements offered a wide range of possibilities for the packaging industry. One highlight at the in-house exhibition was the new application IML-T® Cardboard, which ILLIG presented to the public for the first time. Presentations by the two raw material manufacturers BASF and NatureWorks on bio-based and biodegradable materials rounded off the international customer event.

„The event took place two weeks before Chinaplas and six months before the K trade fair. Despite, or possibly because of, these upcoming major events in the plastics industry, customers accepted our invitation to Heilbronn to find solutions with us in the global packaging debate and to find out about our existing technical solutions,“ said Managing Director Karl Schäuble satisfied.

Influence of the global packaging debate

Sustainability, environmental friendliness, the reduction of plastics and the recyclability of packaging are current global issues that pose a wide range of challenges for the packaging industry. Packaging made of plastic or with plastic content will continue to play an important role in minimising the Hygiene standards and to secure the goods to be packaged. In developing and emerging countries in particular, the pent-up demand is high due to urbanisation.

„From our point of view, the global Development of a circular economy should be given top priority. This requires recyclable packaging and the use of recyclates in the packaging industry. The developments in PET bottles show the possibilities,“ Karl Schäuble told the trade press at the press conference.

The commitment of food manufacturers and retailers should accelerate the global development of recycling systems for packaging. Awareness-raising work on plastic as a recyclable material and the optimal use of this resource should continue.

Packaging development Pactivity®

Under the umbrella of packaging development, ILLIG's Pactivity® has long been involved with the circular concept in the packaging industry and is constantly expanding the aspects of recycling. Optimised packaging can reduce the Use of raw materials and be designed to be recyclable. Thermoformed packaging in particular is thin-walled, resource-saving and economical to produce.

In addition to traditional plastics, the use of alternative and new materials in thermoforming is technically feasible. Current ILLIG thermoforming and mould systems process, for example, bio-based and biodegradable plastics, recyclates and material combinations to produce high-quality, recyclable moulded parts.

„Especially in conjunction with the IML-T®-technology, numerous new packaging variants have been created. This also includes the possibility of producing full cardboard blisters on our packaging systems,“ says Karl Schäuble.

Pactivity® also includes ILLIG configuring or developing the optimum production system for the packaging in question. In this development process, the mould systems in the plants are becoming increasingly important. ILLIG has developed a Consistent tool concept „This will enable us to consistently develop the mould systems, which usually consist of several moulds. A further step towards the implementation of digitalisation in thermoforming towards Industry 4.0,“ added Karl Schäuble.

Sustainable packaging solutions

The focus of the ILLIG in-house exhibition was on current market requirements in relation to recycling and mould systems. In particular, the development and continuation of the IML-T® ILLIG has been recognised in the industry with recyclable monopackaging materials and Plastic-paper packaging Milestones set.

ILLIG presented to the public for the first time the Plastic-cardboard composite pack IML-T® Cardboard. The application was developed specifically for the new „Circular Thinking“ market requirements and is based on ILLIG IML-T®-systems. The advantage of the packaging is that the plastic and cardboard can be easily separated. This enables optimum recycling.

Another advantage from the ILLIG packaging world is the production of full cardboard blisters on an HSA 50d heat-sealing machine. The HSU 35 blister packaging machine for non-food applications and the medical technology sector is also new. ILLIG has technically redesigned the proven sealing technology of the HSP series. The economical and efficient automatic sealing machine with its many features offers almost unlimited possibilities for today's requirements in the packaging industry.

Business development ILLIG

The ILLIG Group continues to grow worldwide. The ground-breaking ceremony for the new ILLIG Maschinenbau S.R.L. assembly plant in Romania took place at the beginning of April. Commissioning is planned for 2020 with an initial 50 employees. A new sales location is currently being built in the Middle East and the continuous expansion of ILLIG service locations outside Europe will continue unchanged.

Over the past three years 2016, 2017 and 2018, sales have increased by a total of around 30 per cent increased. This is primarily due to the new developments presented in recent years and the consistent implementation of the packaging development Pactivity® attributable.

„The increase in sales applies not only in Europe, but especially in the markets in Asia, the Middle East and South America and is also due to the increased demand for packaging machines such as our HSA, BSA and FFS lines,“ said Karl Schäuble on the company's economic situation.

ILLIG assumes that the entire packaging technology market will continue to grow worldwide in the coming years. With the solutions that already exist today, the company can open up additional areas of application in thermoforming.

Irrespective of this, some customers are somewhat more reluctant to make new investments due to the global packaging debate, which is why incoming orders have been below the previous year's level for several months. The number of new projects in progress has increased in recent months compared to 2018, but the decision to make new investments is currently often being postponed. The Objectifying the packaging debate is therefore a task for the entire packaging industry, and existing networks must be utilised consistently for this purpose.

„Communicating life cycle assessments for individual packaging variants and their recyclability is difficult, but this is the only way we will be able to objectify the discussion. Then the uncertainty among consumers and in the packaging industry will lead to growth again, as in previous years,“ predicted Karl Schäuble.

Outlook for the K trade fair 2019

At the K trade fair in October, the company will present the next steps in the realisation of the Digitalisation in thermoforming on the new industry standard 4.0, in which the ILLIG tool system will play a role, among other things. ILLIG is also announcing the first T4th generation hermoforming machine which will set new standards in terms of productivity and reproducibility of the thermoforming process. Another new machine development will be the IML-T®-The focus will be on the decoration of thermoformed lids. In addition to the machine presentations, visitors to the ILLIG K trade fair stand can look forward to a comprehensive range of current service topics.

Source: Illig