Under the working title „HP Indigo Digital Pouch Factory“, HP and Karlville are presenting a complete solution for the production of flexible packaging for the first time. This new solution optimises existing production processes and can reduce the production of printed pouches to a single day.

Various pouches will be produced live in the „HP Indigo Digital Pouch Factory“ during Labelexpo 2019. Films printed using HP Indigo digital printing, the „HP Indigo Pack Ready“ lamination solution and a pouch maker from Karlville will be used.

Compared to conventional methods, this solution reduces the production process from several weeks to a single layer - Converters can therefore also produce smaller runs economically.

„The cooperation between HP Indigo and Karlville is revolutionising the production of flexible packaging - currently the fastest growing segment in the packaging sector. Our solution enables simplified, Consistent and cost-effective production. Converter opens up new areas of business thanks to extremely short throughput times and more resource-efficient production.“

Alon Bar-Shany, General Manager, HP Indigo

Optimised pouch production

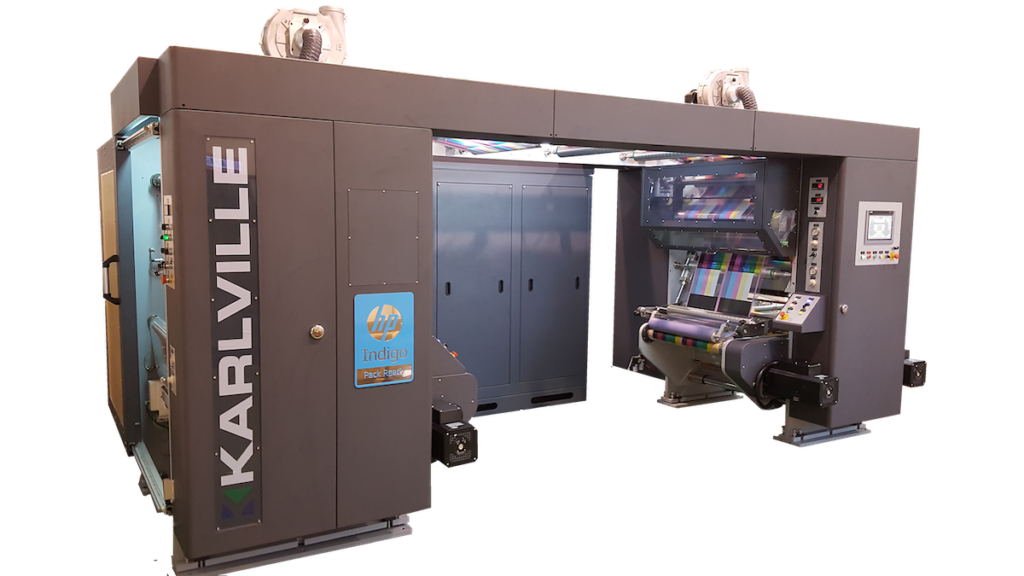

At the HP trade fair stand (5C200), a continuous Web-to-Pack workflow shown. The two digital printing machines HP Indigo 20000 and HP Indigo 6900, the Karlville Pack Ready laminator and the new Karlville Swiss stand-up pouch machine are used to produce various samples - all under the umbrella of the HP PrintOS operating system.

„Karlville developed this finishing solution specifically for HP Indigo. Our aim was to significantly reduce both production times and the complexity of the manufacturing process while keeping costs as low as possible. The Thermal lamination is the most economical approach for label manufacturers to enter the flexible packaging market. The ability to carry out the entire process of laminating, cutting and packaging in a single day thanks to Pack Ready offers completely new opportunities on the market.“

John Price, President, Karlville

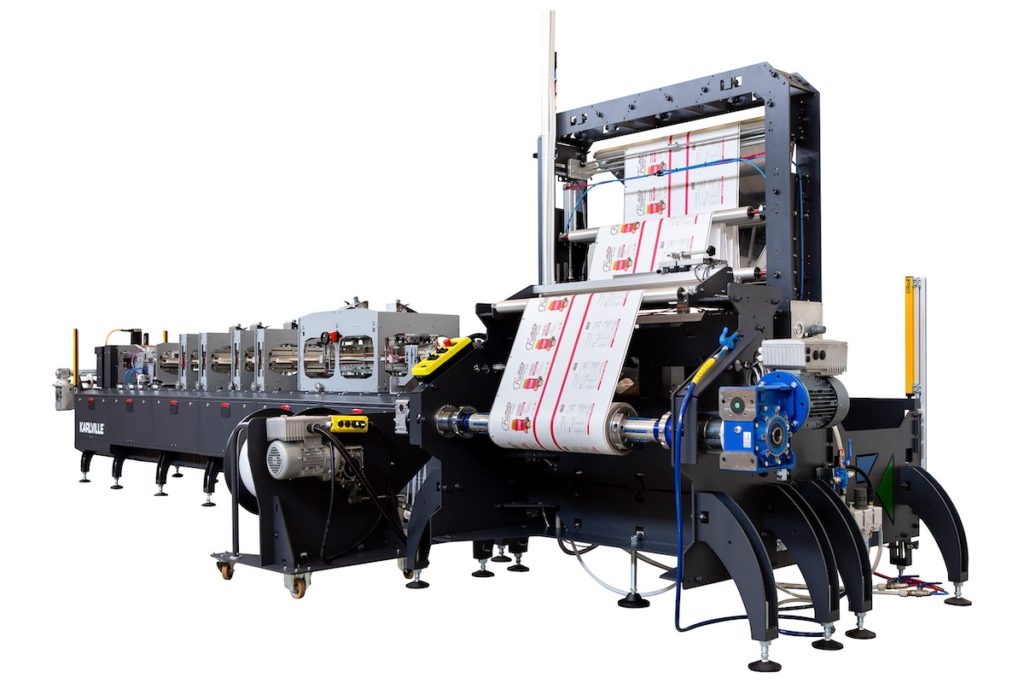

The HP Pack Ready Laminator from Karlville creates a strong laminate adhesion, but does not require any curing time. This makes it possible to cut and pack the material immediately after lamination.

The solution is suitable for a wide range of packaging applications and fulfils the strictest global food safety regulations. It enables converters to build a profitable add-on business for flexible packaging based on an already established material supply chain.

Fast and cost-effective

A Low space requirement, reduced waste and fast set-up times with reduced personnel requirements reduce the total cost of ownership and represent a sustainable and economically attractive solution.

Martin Peroutka from the Czech Republic was the first company in Europe to utilise this solution. Digital Dogma was the pioneer in the USA. Both companies have successfully diversified and can now offer their customers flexible packaging in addition to the production of labels.

The new Karlville Swiss KS-DSUP-400 pouch machines for the HP Indigo 20000 and the KS-DSUP-400-GSW for the HP Indigo 6900 are Quickly ready for use and are also suitable for smaller barrel lengths.

At Labelexpo, the KS-DSUP-400-GSW will be used to produce a 450 x 300 mm pouch that is sealed on three sides - the film is printed in advance with the HP Indigo 6900. This demonstration shows narrow web converters how easily they can expand their range to include flexible packaging thanks to HP Indigo.

Furthermore, a 170 x 280 x 40 mm stand-up pouch is supplied with Additional holographic film manufactured by Nobelus.

Source: HP Germany GmbH