Software, sensors, data and networking are the main players in Packaging 4.0. Multi-head weighers, flow-wrapping machines, traysealers, checkweighers and X-ray inspection systems all collect valuable information. Ishida has developed the Sentinel online software, which networks the machines and seamlessly analyses the large volumes of data.

Data plays a central role in the food factory of the future. The entire production process is digitally mapped and analysed live. After intensive beta testing with hundreds of connected machines, the programme from the manufacturer specialising in packaging technology reached market maturity and has now proven itself in use at dozens of food manufacturers across Europe.

The production lines are controlled remotely, including monitored by means of mobile devices. Because any problems that arise can be recognised and rectified immediately, significant cost savings can be achieved.

Performance analyses made easy

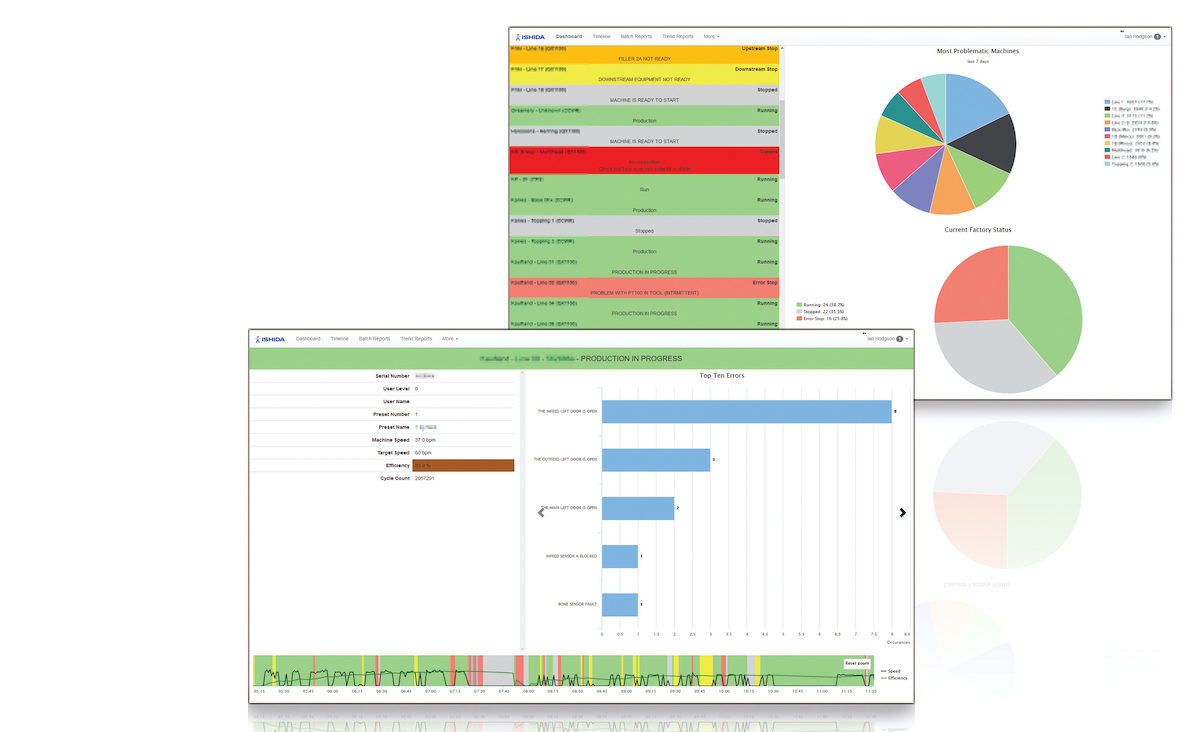

Sentinel offers direct performance analyses focussing on the most important key figures. Users of the software receive customised analyses in real time. Trend values, lot data and statistics. It is also possible to benchmark different packaging lines and production sites. The software collects and stores all information on machine running times, alarm logs and downtimes.

About the Function of the Tracked Changes the changes to the default settings can be traced back and their effects made transparent. Operating errors can therefore be quickly recognised and corrected, and employees can be trained accordingly. The bottom line is increased overall equipment effectiveness (OEE).

Danger recognised, danger averted

Sentinel offers the food industry a great deal of flexibility thanks to its predictive intervention capabilities. Security. The software knows the target status of a system and detects minimal anomalies at an early stage by analysing the data in real time. These deviations signal problems, and rapid detection reduces product loss and helps to increase output.

The Software warns before damage occurs. Technicians can act proactively and prevent expensive downtime. A practical example: In humid production environments, small amounts of water can continuously enter a multihead weigher due to damaged seals.

This gradual process remains undetected until oxidation occurs or the machine suddenly breaks down. By monitoring with moisture sensors, the ingress of moisture can be recognised immediately and Sentinel triggers a corresponding alarm message.

Software users are no longer dependent on fixed maintenance intervals for their machines. After all, regular or even sporadic maintenance has a fundamental problem: every user utilises their machine differently, and the Wear is therefore almost impossible to calculate.

Solution packages for special needs

Sentinel is made available to users in various scopes. The „Reporting Pack“ is predestined for small and medium-sized manufacturers who either do not have their own data monitoring system or wish to outsource it. These companies receive system access and automatic reporting by e-mail to defined recipients.

The detailed and clearly presented reports are available in a variety of languages and provide daily information on the output and capacity utilisation of the machines. In addition to minute-by-minute performance reports and downtime analyses, the reports also include identified recurring problems (the „top 10 errors“) and labelled as urgent.

Interactive web-based visualisers highlight specific time periods and production periods. A practical feature is that users of the software can zoom into the graphics and tables in very small sections.

For small and large food producers with few technical staff of their own, the „Intervention Pack“ the optimum solution. Here, Ishida service technicians have access to the performance data and machine settings.

If rapid troubleshooting is required, there is a Callable contingent of help desk interventions. Test runs for new settings are carried out in consultation with the customer. If a service technician does need to work on site, they can start their work optimally prepared.

Those who opt for the „Service Pack“ who chooses Sentinel receives real-time monitoring of their packaging systems. This comprehensive service package from Sentinel software is increasingly in demand. The fact that many food manufacturers want to relinquish technical responsibility in order to concentrate on their core business is in line with the trend.

Manufacturers with high-performance lines or perishable products also benefit from proactive help desk interventions if performance falls below predefined values. In the event of major faults, the programme sends an automatically generated email to the customer as an alarm message. Communication with Ishida's technicians can be organised through Video conferencing technology in Voice-over-IP mode and via the remote-controlled RCU webcam take place.

Comprehensive protection for sensitive production data

Valuable information from food production requires maximum protection. For this reason, the Sentinel data is stored on a secure SQL server from Ishida. A Direct data retrieval from outside is impossible. During data transmission, the firewall only allows incoming connections with registered IP addresses. The outgoing connection runs via the user's factory network, to which Ishida has no access.

Maximum safety is ensured by a SSL encryption and proxy tunnelling. Only authorised personnel have access to the data on the server. Individual user accounts always have limited access to certain production sites and can only view their data.

Changes to the settings can only be made by selected users. All connections and mouse clicks are logged for complete traceability. For security reasons, machine start and stop commands are always blocked.