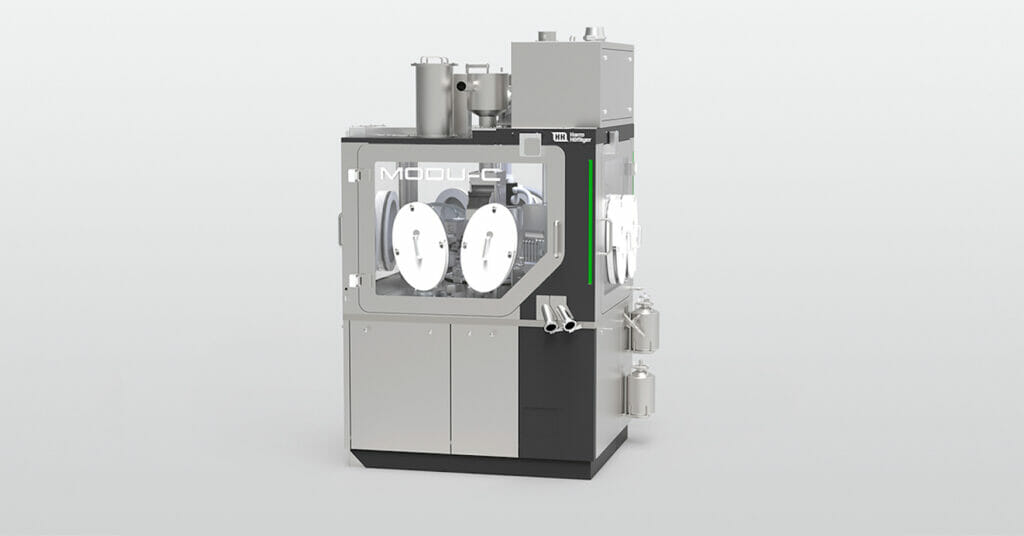

In pharmaceutical development, safe processes are of great importance to ensure that the products reach customers and patients in the highest quality. The new Modu-C CS capsule filling machine from Harro Höfliger fulfils such requirements.

With a capacity of 43,500 capsules per hour, the Modu-C CS from Harro Höfliger for the medium power range. The system is also as a containment variant available.

„The motto ‚Every capsule counts‘ was at the centre of development. On the one hand, this applies to patients who depend on the flawless quality of their medication. On the other hand, it also applies to pharmaceutical development departments - they are increasingly processing sophisticated, expensive powders and other filling media. Product-saving, highly efficient work is particularly important here.“

Klaus Käfer, Sales Director in the Capsule Technologies division

These sophisticated powders include pure active ingredients, freeze-dried powders or so-called highly engineered particles. Many of these substances have complex rheological properties that make the filling process a challenge. make. The trolley system allows the dosing systems to be changed quickly. This means that completely different products can be produced on one system.

„In order to fulfil the promise ‚Every capsule counts‘, we adapt dosing systems and feeders depending on the product properties - and thus achieve the best results, even with tiny filling quantities. Of course, all standard powder blends and pellets can also be processed reliably with our CS.“

Klaus Käfer

Source: Harro Höfliger

More news about packaging machines

White paper | How to make packaging machines more dynamic through lightweight construction

Three applications, one solution

Packaging machine manufacturer in flow

Sacmi acquires majority stake in Groupe Emballage Technologies