Sustainability and the conservation of resources are also key topics in the field of labelling. At the Hannover Messe, Bluhm Systeme will be presenting solutions for the international movement of goods that utilise ecologically sound raw materials and at the same time use resource-saving processing.

Among the solutions that Bluhm Systems in Hanover is the NoLiner, a label printing dispenser that Labels processed without backing material and therefore sustainable and cost-effective labelling is possible. The system has an atomisation unit that applies a fine water-based liquid film to the back of the label during printing. The elimination of the label liner layer saves resources and reduces waste costs. Label rolls without liner also hold more label material with the same roll diameter.

The two-colour Markoprint integra PP 108 Bicolor inkjet printer marks with a print height of up to 108 mm. Robust against vibrations, it also feels at home in challenging production environments. A unique feature is the bicolour version, which uses two ink colours simultaneously, e.g. for GHS labelling in black and red with just one device. The Legi-Air 6500 is a Combination of colour label printer and label dispenser. The system prints colourful labels with a resolution of 1,200 x 1,200 dpi at lightning speed and applies them to products of different heights.

The Linx 8900 continuous inkjet printer continuously monitors the ink levels and viscosity. Ink and solvent can be refilled quickly and easily. The print head cable is up to 6 metres long. It can be used in ambient temperatures from 0 to 50 °C. The Geset 221 labelling system is a versatile system for automatic labelling of cylindrical products. It offers a cost-effective entry-level option for the fully automatic wrap-around labelling of cans, bottles, buckets or canisters with diameters between 25 and 125 millimetres and heights between 30 and 300 millimetres.

Source: Bluhm Systems

Bluhm Systeme at the Hannover Messe: Hall 6, Stand E62

More news on labels and labelling

CCL Industries expands labelling expertise

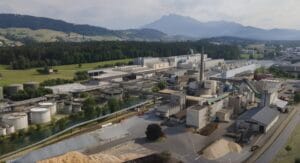

Perlen gets into moulded fibre packaging

Autajon Group strengthens presence in the Netherlands

Volati takes over Interket Group