Consumer and brand protection, traceability along the entire process chain, protection against product piracy, environmentally friendly packaging solutions, waste reduction and legally compliant labelling - today's requirements for product and packaging labelling could hardly be more complex and changeable. Domino has been synonymous with coding, marking and labelling systems for almost 45 years.

Today is Domino a leading provider of industrial coding, marking and labelling solutions that are used in production and logistics environments worldwide. The systems can be used to apply expiry and traceability data, batch, lot and test numbers, metre and inch markings as well as logistics information to products, packaging and pallets. They also include monochrome and full-colour digital printing systems for label and packaging printing to the product portfolio.

Continuous inkjet technology on the rise

Domino was founded in 1978 by Graeme Minto. As project manager at Cambridge Consultants Ltd (CCL), he had led a customer project to develop continuous inkjet technology (continuous inkjet printing). Although Graeme Minto's client lost interest in the project, the visionary himself was convinced that it was a promising technology. Therefore He acquired the necessary licence and literally founded a garage company.

Graeme Minto was fortunate when the company began to grow in the early 1980s. This was due in no small part to the support of EU legislation, which required perishable goods to be labelled with expiry dates. Continuous inkjet technology (CIJ) is the ideal process for these requirements. With the introduction in Unijet, developed in 1978, was able to label around 4,500 to 30,000 products per hour. become.

In 1985, the founder floated Domino on the UK stock exchange and decided to hand over the management of the company to a management team with more experience of running large companies. He himself became Chairman, but after four years he moved on to other things, leaving behind an up-and-coming company with an extremely attractive, sought-after technology.

In search of further technologies

But Not every product and packaging can be optimally labelled using CIJ technology. Domino's Management Board very quickly recognised that limitations associated with this technology, such as high product speeds, moisture films on product surfaces, general surface properties and shapes, substrate materials or production steps such as steam sterilisation in different sectors, represented both a threat and an opportunity for the company.

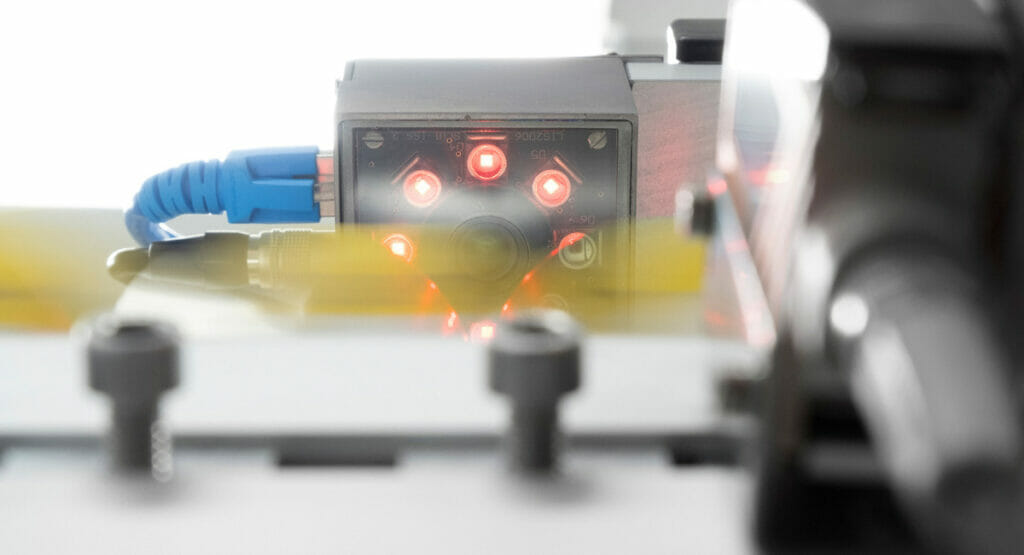

Those responsible were aware that it was not possible to focus on just one coding technology, as it could cover many but not all applications in terms of product and packaging materials, and that the company's rapid growth would soon stagnate without further specialisation and expansion. Domino has therefore expanded its Product portfolio continuously expanded over the years with additional technologies. As a result, the Laser technology (CO2-laser, fibre laser and, more recently, UV laser), thermal transfer printing, the piezo inkjet process and thermal inkjet technology. as well as label printing and dispensing solutions were gradually added to the product portfolio. This means that all coding, marking and labelling applications can be served.

As a designer, developer and manufacturer of today's comprehensive range of coding, marking and labelling systems (including industrial camera systems for code checking and verification), the company provides manufacturing companies with a wide range of products. customised system technologies available, with the help of which all Labelling requirements from the product to the pallet can be operated.

More than just a marker

The Digital printing industry is fundamental to Domino's continued success. Digital Printing Solutions, a separate business unit within Domino Printing Sciences plc, provides solutions for the commercial printing industry and label presses for printing full-colour labels using the digital printing process.

„Domino. Do more“ means making an impression for all Domino employees - the best impression, especially on customers. Because production for customers has priority. The Experts know the market and legal requirements of the individual sectors and speak their language. They are trained in-house to find the best solution in each case.

Focus on special corporate values

„Thanks to our competent employees, we know our customers“ requirements, think ahead for them and always provide solution-oriented advice," emphasises Götz Kroeber, Managing Director of Domino Deutschland GmbH. He is an engineer and has been familiar with the coding and labelling industry and its requirements for many years. Götz Kroeber joined Domino Deutschland in November 2012 as General Sales Manager and was appointed Managing Director with effect from 1 June 2019. For him and all employees Collaboration, listening, competence, ambition and responsibility are of the utmost importance. in.

„As a global company, we are in the fortunate position of being able to utilise the expertise and experience of a large number of brilliant minds around the world. However, this is only possible if we work together as one. That's why we endeavour to foster a culture of collaboration in everything we do, so that everyone can contribute their ideas and help improve the company. Collaboration is also crucial when it comes to our customers and forms the foundation of our customer relationships.“

Götz Kroeber

One of the ways of working together more effectively is active listening. The company is continuously working internally to strengthen its competences. This includes the realisation of Compliance with global regulations, Industry 4.0 and smart production, sustainability in manufacturing and waste reduction. A fairly recent example is the acquisition of Lake Image Systems.

„This was the result of our commitment to developing our machine vision capabilities because we recognised that quality control and data validation are hugely important to our customers. In addition to our customers, we also have a responsibility to our stakeholders, to everyone within the Brother Group, to the communities in which we operate and to the environment. We can do none of this without our skilled and dedicated employees. They are the driving force behind Domino.“

Götz Kroeber

Bundled potential

Domino has been a trusted sparring partner to manufacturing companies and machine builders (OEMs) in numerous industries for more than 40 years, providing them with its coding and marking solutions and the know-how of its industry experts. Uncomplicated. Human. Solution-orientated. Effective.

As the German sales and service subsidiary of the global Domino Printing Sciences group of companies, the industrial coders from the Domino Deutschland GmbH provides manufacturing companies with efficient solutions for industrial product and packaging labelling and brand protection. The company specialises in the various requirements of different industries such as food, beverages and life sciences.

„Our industrial printing expertise and reliable solutions help manufacturers worldwide to produce sustainably, reduce waste and at the same time attract, inform and protect consumers,“ summarises Götz Kroeber.

http://www.domino-deutschland.de

More news from the magazine

Translucent paper seal labels for pharmaceutical packaging

Packaging machine manufacturer in flow

Powerful automation for mills

Decentralised signal processing with the Schmersal Safety Fieldbox