Powerful automation for mills

How four mills master the sack with Koch robot systems - from manual labour to high performance and into the automated future.

The trade magazine for the packaging industry

The trade magazine for the packaging industry

Five years ago, Linhardt's declared aim was to use recycled material, known as PCR material, in the plastic tubes it produces, and today a high percentage of this is the case. It was therefore a logical step for the company to decide two years ago to follow the same path for aluminium tubes and cans. Taking stock:

The Linhardt Group, manufacturer of plastic and aluminium tubes and cans, is a typical medium-sized family business. Not only since the "Fridays for Future" movement has the company seen itself as responsible for holistic, sustainable action and as an innovative driver in the industry. This applies to all processes in procurement, production, logistics and sales, but above all at product level. The basis for new developments is the primary goal of Material avoidance, the development of reusable packaging, the conversion of products to mono-material packaging and the use of recycled materials.

"About three years ago, we were faced with the question of which recycled material we could use for our aluminium products and in what proportion," emphasises August Wanninger, Director Innovation & Product Development at the Linhardt Group. Which PCR materials are actually available in sufficient quantities? And last but not least: What quality is really necessary for our manufacturing process? "Ultimately, we want to contribute to a meaningful circular economy with our product development. Hence the provocative question we asked ourselves," Wanninger continues: "Is recycled aluminium in packaging sensible, honest and responsible?"

There are a whole series of important facts that stand for aluminium as a very high-quality and valuable material and that have encouraged the company to investigate aluminium recycling more closely:

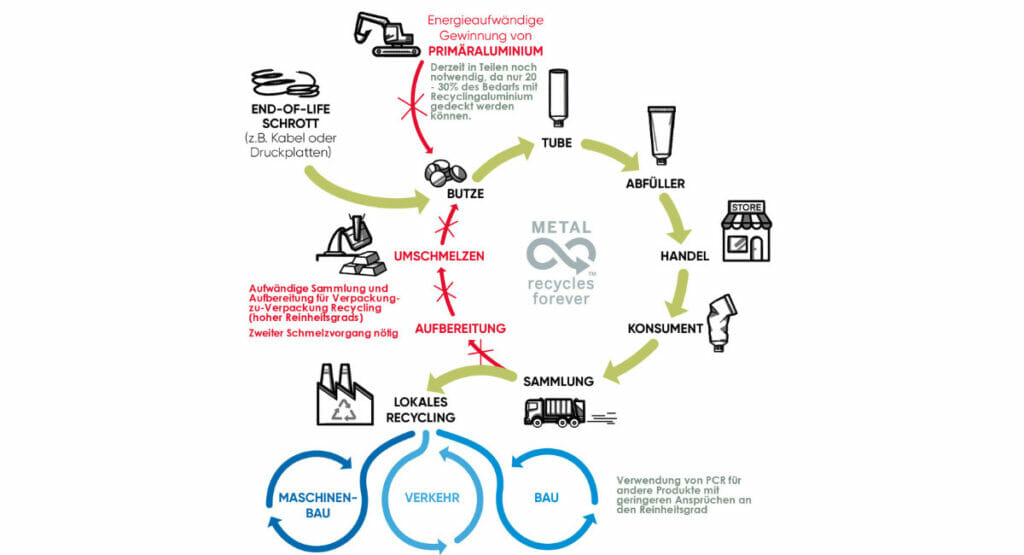

Based on the fundamental approach, Linhardt's focus was on the The focus is on the question of whether "packaging-to-packaging recycling" is sensible, honest and responsible. is. The following answers were developed in an intensive process.

The company's approach was and is to deal with and communicate the topic openly and honestly so as not to be accused of greenwashing. This is why the DIN was consulted. After all, an official standard should be beyond reproach as far as credibility is concerned. In this case, it is the DIN EN ISO 14021:2016, which regulates what is considered post-consumer recyclate (i.e. PCR) and what is not. The DIN clearly states that PCR aluminium is produced by recycling material that can no longer be used for its original purpose. It is therefore Recycling of "waste after use" or, in other words, "end-of-life scrap". So explicitly not production waste. It would be even better to say: material that is at the end of its life cycle, because after recycling it is about to be reincarnated in the form of a new product.

According to DIN, this end-of-life scrap can be made from Private, commercial, industrial or institutional use originate. And this was the point at which discussions first arose that continue to this day. Terms such as "real PCR" are used in the market, as the recyclate is obtained from products that were used directly by an end user, i.e. a natural person, and ended up in the Yellow Bag. The question now arises as to whether there really is "real" and "unreal" PCR. What is important is the fact that Material remains in the cycle and is not lost. Regardless of whether it was used by an individual or a company before recycling. This raised the question for those responsible: which aluminium recyclate makes more sense for tubes and cans?

Closed loops are an important building block for a sustainable economy. This requires an increase in recycling rates and the utilisation of recyclates in new products (see graphic).

For the production of aluminium tubes and cans using the extrusion process, minimum technological requirements are placed on the purity of the aluminium. Today, for example, aluminium is used in the Tube production with an aluminium purity level of 99.7 percent. The minimum requirement is around 99 per cent in order to be able to press the material into tubes without cracks or holes forming.

Should therefore, in the sense of a closed product cycle If tube and can scrap from the Yellow Bag were to be reprocessed, there would be the problem that the required degree of purity could not be achieved without additional processing, e.g. in the energy-intensive pyrolysis process. can be processed. After this usually complex preparation and the first melting down, the slug manufacturer then melts it down again in order to be able to produce a cast-rolled strip for slug production (primary material for tube production) from the liquid melt.

"We, on the other hand, have opted for an alternative approach and, together with one of our slug manufacturers, have found a way to melt down cable scrap and used litho plates directly and without any detours in a double chamber furnace."

August Wanninger

These raw materials were selected because they have an inherent purity of over 99 per cent in aluminium and can therefore be melted down directly without special pre-treatment and immediately converted from the liquid melt into a cast-rolled strip and slugs. Thus saves the tube manufacturer the high energy consumption and thus the CO2-emission for pre-treatment and the second melting process.

For the Linhardt project, this was the key to their approach of producing PCR material with the lowest possible CO2-emissions. In addition, in the original product cycle, small quantities would often have to be transported from many decentralised locations and with complex sorting to the special pyrolysis plants, whereas the Cable scrap and lithographic plates are usually collected where they are generated and delivered to the slug manufacturer directly or via a maximum of one intermediary become.

The tube and can scraps with their lower degree of purity, on the other hand, can be used for other future applications in machine, vehicle or building construction, for which their quality is sufficient.

The International Organisation of Aluminium Aerosol Container Manufacturers (AEROBAL) and the European Aluminium Slug Producers (ASP), which operate under the umbrella of the Aluminiumverband Deutschland e. V. (AD) had therefore commissioned the renowned Swiss research institute Carbotech to carry out a study to deal with this topic in more detail. In this study confirms that material loops often have ecological advantages over product loops. have.

"The best strategy is to focus on high collection and sorting rates in order to maximise the amount of aluminium that remains in the market in terms of a closed material loop. This should further improve recycling results, as this will reduce the environmental impact in the long term, regardless of the application into which the recycled material flows."

Dr Fredy Dinkel, Carbotech

"Ultimately, all our efforts to develop innovative and sustainable products are about minimising the environmental impact of our packaging as much as possible," says August Wanninger.

After the Carbotech study had confirmed Linhardt's approach, the third question was the actual achievable difference in CO2-emissions: Of course it is marketing-effective to minimise the percentage of CO2-savings to be awarded. However, the only factually relevant comparison is how much CO2 is released during the production of a tube made of virgin aluminium and how much is released when using a high PCR aluminium content. The absolute savings based on the actual CO2-emissions is the decisive factor here.

Literature values or industry averages are still often used to calculate the highest possible theoretical CO2-emissions as a basis and thus be able to specify a high percentage saving. For the CO2-footprint has a large difference whether I buy virgin aluminium from China, India or Europe, as the CO2-emissions from aluminium production in China, for example, may well be twice to three times as high as in Europe.

"The Linhardt benchmark is a maximally utilised, but also honestly declared CO2-savings when comparing the previously used virgin slug with the new 100 per cent PCR slug from the same supplier," explains August Wanninger. In terms of material alone, this results in a saving of around 92 per cent. However, what is much more important and meaningful is a absolute saving of twelve tonnes of CO2e per tonne of aluminium used. In addition, the life cycle assessment from which these values originate was externally audited by a third party. Also Tube manufacturer Linhardt can determine the savings potential of customer packaging on a customised basis using its own LCA tool and thus provide its partners with a concrete decision-making aid.

In addition, the supply chains of all materials are traceable and completely transparent. More importantly, the PCR slug suppliers have received confirmation from an independent audit that the procurement and processing of PCR slugs meets the requirements of ISO 22095:2020 - Chain of Custody. This means that the Scrap, litho plates and cable wires are purchased directly from the previous owners or from scrap dealers within a maximum radius of 750 kilometres from the European slug manufacturers. This is also in line with the responsibility arising from the Supply Chain Duty of Care Act.

"Today, we can see that the use of alternative sources of recyclate leads to the greatest possible saving of tonnes of CO2 with transparent and short delivery routes. We have finally put this into practice and are now able to offer our customers aluminium tubes and cans made from 100% PCR aluminium and therefore a significant CO2-savings."

August Wanninger

How four mills master the sack with Koch robot systems - from manual labour to high performance and into the automated future.

Packaging machine manufacturer Meypack relies on Schmersal's Safety Fieldbox for safety-related signal processing. This concept benefits not only the designers, but also the users of the machines.

Since 1925, the Nivea cream can has borne its deep blue colour, white lettering and round shape - a design that has remained stable over generations, markets and crises and is now celebrating its 100th birthday.

Edding AG and Elried Markierungssysteme decided to combine their strengths back in 2018.

In his new column, our „packaging user“ takes a look at a business in which packaging and marketing have long since become more important than the actual content: the jersey. What was once a symbol of loyalty and identity is now degenerating into a seasonal disposable product - from carnival jerseys and limited special editions to „reinventions“ every year. A trenchant look at football, consumption and the question of how much sustainability there really is in polyester.

The requirements for transporting temperature-sensitive products are high, especially in the pharmaceutical industry. Eutecma has specialised in the cold chain with modular, reusable packaging solutions.