For over 60 years, Greiner Packaging has stood for a high level of solution expertise in the development, design, production and decoration of stable plastic packaging. Today, the company is one of Europe's leading manufacturers for the food and non-food sectors and is committed to innovation for a circular world.

With the guiding principle „Reduce, Reuse, Recycle“, the company focuses on maximum recyclability in combination with responsible use of existing resources through conservation and reuse: reduce what can be avoided (reDUCE), utilise what can be reused (reUSE) and recycle what cannot be reused (reCYCLE). All three „Rs“ are important building blocks for the future of packaging.

Back to the beginning

In its more than 150-year history as a family business, the company has Greiner from a small general store to a leading global group of companies with more than 10,000 employees in 30 countries. Today, Greiner is known as a leading producer of plastics, but the company's roots go back to a different material - cork. Carl Albert Greiner and his wife Emilie open a small general store in Nürtingen in 1868, selling, among other things, soda water filled in bottles with handmade cork stoppers

Just ten years later, Carl Greiner receives the patent for his cork cutting machine, which makes the manual cutting of corks obsolete. From now on, other beverage producers are also supplied with corks. Shortly before the turn of the century, in 1899, her son took over the management and set up a cork stopper factory with 45 employees in Kremsmünster, Austria. The start of something really big has been made.

The transition from cork to plastic

In the 1920s, the company was already internationally networked and active, with branches in Europe and Chile and exports to Australia, Asia and America. Due to the high customs duties that were introduced in the exporting countries around 1950, Greiner also began to work with other materials.

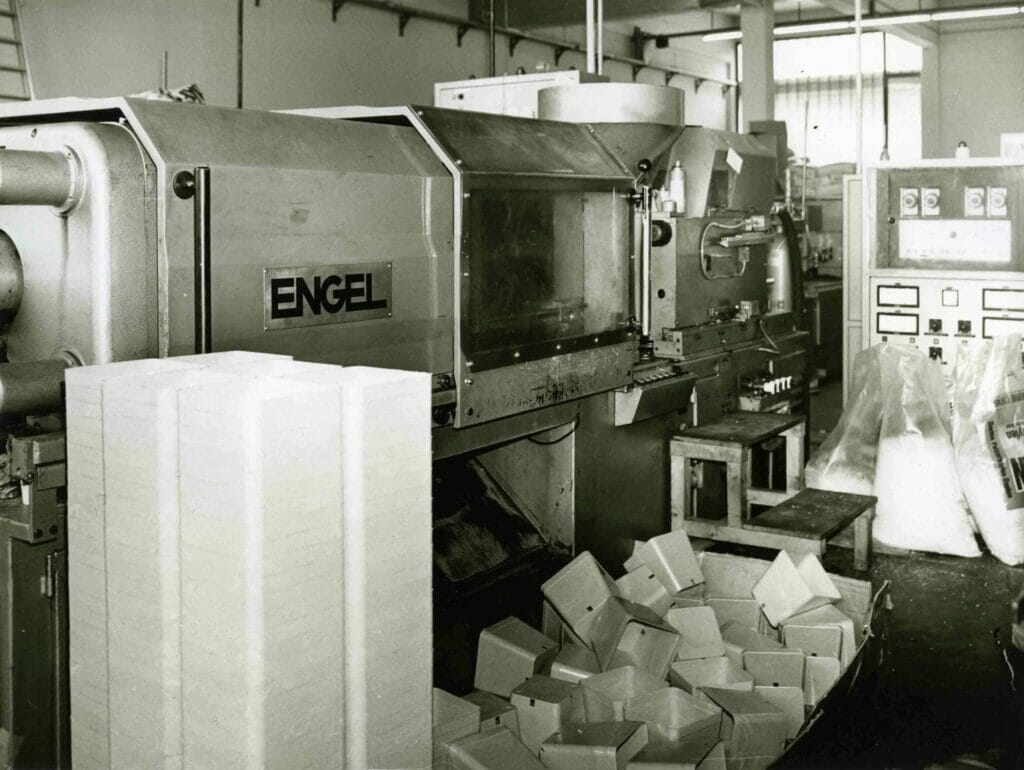

This led to two injection moulding machines being put into operation in 1960 and the first plastic cups being produced. This is the starting signal for Greiner Packaging as we know it today. The issue of sustainability has always played a major role for Greiner Packaging, which can be seen, for example, in the expansion of the business to include multilayer films in 1987. Regenerated material is incorporated into the centre layer of the film - the best example of the company's progressive packaging standards even back then.

The great expansion

Just two years later, Greiner Packaging is one of the first companies in Austria to expand into Eastern Europe. Greiner Packaging continues this expansion strategy consistently in the following years. The Greiner Assistec business unit was created in 2006 from the „technical parts“ production area, which had already existed for many years, and internationalisation continued in 2010. The first location outside Europe is established in Monterrey, Mexico. Together with an international customer, the Assistec business unit enters the market. The first US location in Pittston, Pennsylvania, follows a few years later.

At the present time, Greiner Packaging on three continents in 19 countries with over 30 locations and more than 4,900 employees active. The company offers a wide range of technologies, decorations and innovations and can proudly look back on many satisfied customers. Despite the immense growth, the company is still family-owned - a fact that is also reflected in the company culture. „When I look back on my 39 years at Greiner Packaging, I can proudly say that we have developed a regionally operating company into an internationally successful company that is still family-owned and where the focus is on the employees,“ emphasises Harald Steiner, Vice President Global Technology & Excellence.

And what happens next?

Not only is the company growing, but also the criticism of plastic as a recyclable material. Greiner Packaging has been interested in sustainable production since its beginnings. While the initial motivation was to use resources as responsibly and sparingly as possible, climate and environmental concerns are now a priority: „With its sustainability strategy, Greiner Packaging is ideally equipped for the future. From the recyclability of our existing products to new products and business models, we are working intensively on innovations - with the aim of being able to offer our customers the best possible products and solutions,“ emphasises Manfred Stanek, currently still CEO at Greiner Packaging.

In 2022, the guiding principle „Join the Circular Revolution“, with which the company is committed to the three main objectives of Reduce - Reuse - Recycle. The company's innovative expertise not only covers a wide range of materials and technologies, but also constantly strives to develop innovative ways of conserving resources. Because one thing is clear: it takes bold and creative ideas to really make a difference.

Greiner Packaging is pursuing different directions for success, for example K3: Plastic and cardboard. One innovation that the company can look back on with particular pride is the cardboard-plastic combination that first saw the light of day in 1982 and has been continuously developed ever since. Correctly separated and disposed of, both components - the unprinted plastic cup and the cardboard wrap - are optimally recyclable. If the consumer does not separate them, the latest innovation from Greiner Packaging provides a remedy: K3 r100, the first K3 cup in which the cardboard wrap separates automatically from the plastic cup during the waste disposal process.

Another approach that Greiner is pursuing is the use of r-PET. Good availability, food suitability plus high quality - these properties make r-PET a valuable material when it comes to sustainable packaging. This is because r-PET is currently almost the only material that can be mechanically recycled and used for food applications. In 2022, Greiner Packaging took over a Serbian r-PET flakes producer, making recycling an integral part of the business division. The company is constantly striving to optimise both the material itself and processes for material processing and decoration options. For example, in addition to the already well-functioning bottle stream, the company is committed to establishing a tray-to-tray recycling stream for r-PET so that in future, PET cups, tubs and trays can be recycled and processed into new packaging in addition to bottles.

A look into the future

Greiner Packaging will not stand still in the future. Firstly, there will be a change at the top of the company in May 2023Manfred Stanek, who has held the position of Chief Operating Officer at Greiner AG since January 2023, will be succeeded by Beatrix Praeceptor, an experienced manager, as the company's first female managing director.

On the other hand, the journey towards a circular economy has only just begun, the climate discourse is in its infancy and much still needs to be done to achieve the company's ambitious goals. Greiner Packaging is looking forward to tackling these challenges together with the entire industry.

More news from the packaging sector

Confectionery: Flavour alone is no longer enough

Croxsons launches first British sparkling wine bottle on the market

adapa completes refinancing

Interaction of machine, adhesive and application technology